The Operations1 Blog

Read our latest articles about connected work, digital work instruction and checklists, operational processes and innovative software and technology.

Latest articles on Connected Work

The Production Summit Allgäu 2024 impressively demonstrated that the German industry is on the verge of a profound transformation. The key themes of the summit—digitalization, automation, global competition, and the need for flexible production systems—highlight how urgently a shift in production thinking is required. It wasn’t just about technological innovations but also fundamental strategic and societal questions that will shape the success of the industry in the coming years.

Benjamin Brockmann

Oct 9, 2024

Amidst the rapidly evolving manufacturing landscape, Operations1 has secured a significant position in the prestigious Gartner Hype Cycle for Manufacturing Operations Strategy, 2023. As this trend gains momentum, with 5% to 20% market penetration, signaling a promising adolescence stage.

Markus Glotzbach

Aug 2, 2023

When it comes to change management, many people react with resistance and fear of change. Yet change management is often the key to a company's success and satisfied employees. As Head of Customer Success at Operations1, Rafael Koch has been involved in many change management processes. In this interview, he reveals the secret of successful change management and why it is so important to involve employees.

Markus Glotzbach

Jan 26, 2023

Companies that believe that the only chance of digitization lies in finally getting rid of the mountains of documents are thinking too short of the issue. Digital processes are just the tip of the iceberg, as Stefan Philipp knows. The Head of Solutions at Operations1 and his team have already successfully supported many companies on their way toward connected work. In this interview, he provides in-depth insights into how networked working can optimize processes to such an extent that productivity and employee satisfaction increase significantly and six-figure sums can be saved at the same time.

Markus Glotzbach

Jan 17, 2023

"See digital technologies as partners": Interview with Bernd Hausler

The fear that technology will curtail the frontline worker's job as it develops is widespread. However, if the requirement profile of operational employees shifts more towards conceptual activities in the coming decades, this fear is unfounded.

Bernd Hausler, Managing Director at ifm, the leading supplier of innovative automation technology, takes the clear view in an interview with CEO and Co-Founder Benjamin Brockmann: "For me, people will remain the focal point in production in the future."

Benjamin Brockmann

Jan 11, 2023

The shortage of skilled workers is one of the greatest challenges facing the manufacturing industry. It is not just a question of knowledge that is lost with the retiring experienced workforce, but also serious consequences such as declining productivity. What has been missing so far is a consistent digitization strategy that embeds the operational employee in a comprehensive digital system of connectivity.

A Connected Worker Platform represents such a solution approach, because it offers three central levers that sustainably protect against a shortage of skilled workers: knowledge retention, productivity enhancement, and employee retention.

Editha Bertsch

Sep 29, 2022

Total Productive Maintenance (TPM) is a comprehensive maintenance concept to enable a trouble-free production system. In our detailed TPM guide, we explain the complex term and its history, explain the different building blocks of TPM, go into the advantages and disadvantages of the method using examples, and illustrate the introduction. In the end, it becomes clear that companies that want to move with the times cannot avoid digital TPM.

Editha Bertsch

Aug 10, 2022

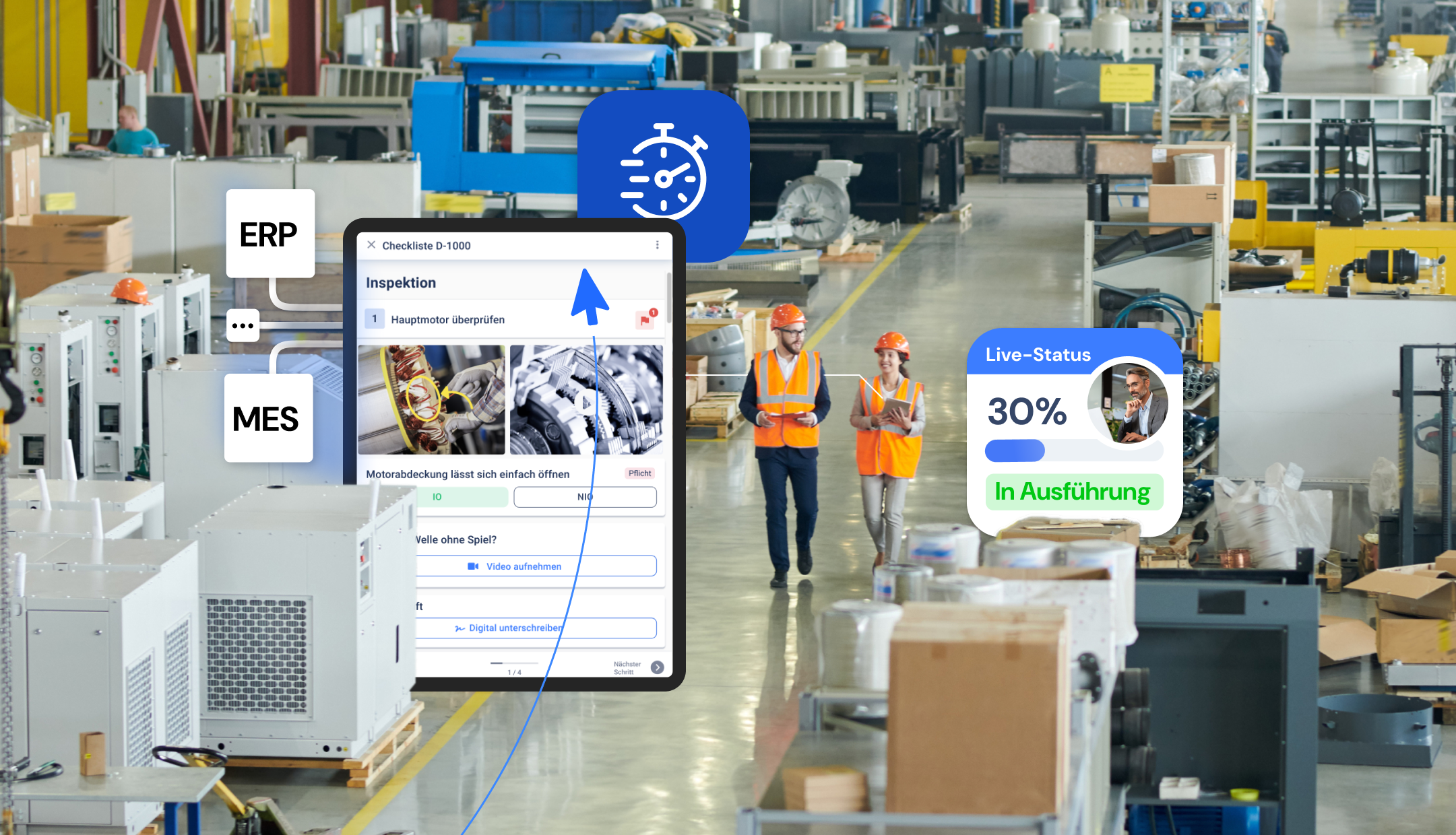

A Connected Worker Platform represents a new category of technology that puts people at the center of the production environment. In this compact guide, you will learn why this is important, how you can proceed to implement a Connected Worker Platform, and what results you can expect.

Markus Glotzbach

Aug 2, 2022

The connection of operational employees has arrived on the agenda of international executives of manufacturing companies. Pioneers can already measure enormous successes, while the majority of companies are still at the stage of paper, ERP interfaces on the shopfloor and fragmented in-house developments.

Markus Glotzbach

Jun 30, 2022

On 10 and 11 May 2022, we as Operations1 were nominated as one of the top 5 start-ups in the field of production and were thus able to engage in an exchange with many executives from Germany's most innovative factories. What was particularly motivating about this was that instead of focusing exclusively on the short-term challenges in global supply chains, the focus was particularly on the topics of sustainability, value orientation and digitalisation.

Benjamin Brockmann

Jun 2, 2022

We changed our brand from cioplenu to Operations1. Our goal is to support operational employees worldwide in their daily work! Therefore, we have decided to manage the software and our team under Operations1 to firmly anchor this ambition in our brand as well.

Benjamin Brockmann

Nov 8, 2021

Buzzwords like Industry 4.0 or Smart Factory are on everyone's lips. Most manufacturing companies are already investing heavily in digitization. However, this often creates data silos and increases complexity for operational employees.

Adaptive Process Execution Software helps to think holistically about the production process, to focus on the operational employee and to network the organization.

Benjamin Brockmann

Oct 26, 2021

There are many reasons for opening a new production site or relocating production. What is always required, is to transfer existing knowledge to the new location as part of knowledge management. We show you how.

Editha Bertsch

Oct 26, 2021

The HSSE area includes extensive guidelines and processes that require strict compliance. However, compliance auditing is often done in paper form. Adaptive Process Execution Software provides HSSE teams with a real alternative. We show how.

Editha Bertsch

Oct 26, 2021

Companies strive to continuously improve their organizational structures, processes and operations. The basic principle of the "Continuous Improvement Process" is often used for this purpose.

Process optimization can, for example, refer to increasing quality, reducing lead times or lowering costs.

Markus Glotzbach

Oct 25, 2021

Latest articles on operational processes

Quickly boost productivity - The demands on manufacturing companies are constantly increasing: rising cost pressure, more complex products, a growing shortage of skilled workers, and ever shorter innovation cycles. The shopfloor, i.e., the direct production level, is at the heart of this. But this is where traditional, paper-based processes quickly reach their limits.

Many companies are therefore faced with the question: How can they make the transition to a digitalized shopfloor without months of projects and high investments? The good news is that digitalization does not have to be complicated. With the right approach, productivity, quality, and process reliability can be increased in record time.

Markus Glotzbach

Sep 3, 2025

Increased process reliability and flexibility for your shopfloor employees - Production managers do not have an easy job in their day-to-day work: they must always ensure a high level of occupational safety, keep track of employee qualifications, ensure that new employees are trained quickly, and respond flexibly to personnel shortages in processes. But where Excel lists, paper-based processes, and unsecured knowledge pose problems for personnel managers, digital tools for qualification and knowledge management can provide enormous support.

Markus Glotzbach

Aug 16, 2025

In production, a company's ability to train new employees quickly and effectively is crucial to its success. Fast induction increases productivity and reduces errors, waste and rework. If a company manages to train employees quickly and effectively, new employees can reach their target productivity up to 70% faster.

Editha Bertsch

Sep 19, 2024

Find out how the potential of modern manufacturing can be utilized in the best possible way.

Future Manufacturing Event in Frankfurt

Benjamin Brockmann

Apr 25, 2024

Webinar recap: Digitizing quality control processes in mechanical and plant engineering

Mastering current challenges for machine and plant manufacturers.

Markus Glotzbach

Nov 22, 2023

Improve employee-led quality control through digitization.

Markus Glotzbach

Oct 16, 2023

Solutions to the challenges in paper-based commissioning.

Markus Glotzbach

Sep 21, 2023

Professional inspection protocols are the basis for successful commissioning processes.

Markus Glotzbach

Sep 4, 2023

Digitization projects in the manufacturing industry are still neglected. Instead, the focus is on the core processes - i.e., production itself. Downtimes of production facilities cause high costs and weaken the resilience of a company.

A preventive maintenance strategy can remedy this situation - and do so even more sustainably if the concept of digitization is taken into account. Our blog article explains how this can be done.

Markus Glotzbach

Sep 13, 2022

Autonomous maintenance helps workers take more responsibility for their plant by removing the strict division of tasks between production and maintenance. Among other things, companies can thereby increase their productivity, reduce costs and position themselves for the future.

This blog post will provide you with comprehensive information about the concept of autonomous maintenance and explain the benefits as well as how to implement it. Read at the end what added value a digital maintenance approach offers and how our software solution supports you in this.

Markus Glotzbach

Aug 24, 2022

Corrective maintenance is also known as reactive maintenance. The aim here is to eliminate machine downtimes as quickly as possible and sustainably. Preventive or predictive maintenance are alternatives or supplements to this approach.

Markus Glotzbach

Jul 29, 2022

Manufacturing companies are increasingly confronted with a variety of challenges: external shocks such as pandemics, wars and global supply bottlenecks are forcing medium-sized companies in particular to become more agile. Internal market developments such as the shortage of skilled workers, an increasing demand for high product diversity, and shortened product life cycles add to the difficulty. The methods and tools of lean management are therefore more important than ever many years after they were first described. The good news: it is easier today than ever before to implement them.

Benjamin Brockmann

Mar 28, 2022

Efficient and lean production processes not only save money. Companies can secure their long-term success by avoiding wasteful, non-value-adding activities. In contrast, paper-based work instructions and checklists are in stark conflict with lean working methods. Companies that want to increase their productivity and improve their product quality should banish paperwork on the shop floor in favor of software.

Editha Bertsch

Mar 7, 2022

Operational excellence is no longer an option - for companies that want to survive in volatile, unsteady waters, there is no alternative. Numerous methods and instruments have developed around the management approach to support the achievement of objectives. Lean Management, Kaizen or Six Sigma are just a few examples. Another underestimated lever for achieving excellence goals is digitalization. We explain what operational excellence is and how you can take advantage of digitization to achieve excellence goals.

Daniel Grobe

Feb 28, 2022

Machines and systems, but also building services installations, must be inspected and maintained at regular intervals to ensure that production operations run smoothly. Maintenance plans are an integral part of maintenance and must therefore be carefully attended to at all times.

Editha Bertsch

Oct 25, 2021

Complete and careful documentation in the outgoing goods department is essential, because it protects you from high costs in the event of unjustified complaints.

Learn how to achieve this with digital checklists and what should definitely be included in your outgoing goods checklists.

Markus Glotzbach

Oct 26, 2021

The responsibility for quality is increasingly being transferred to manufacturing departments. Worker self-inspection is an increasingly popular topic. Some experts are supporting it, while others are voicing their concerns.

Daniel Grobe

Oct 20, 2021

Many manufacturing companies still use paper-based checklists in quality inspection. However, static inspection documentation poses several quality risks at once.

Daniel Grobe

Oct 20, 2021

Even before Covid-19, a smooth exchange between two shifts was an integral part of production operations. Short-time work, home office or even changed production processes increase the need for seamless information transfer. Digital shift handover protocols create transparency and process reliability.

Markus Glotzbach

Oct 22, 2021

In many industrial companies, more and more frequently necessary retrofitting causes unproductive times for employees and production losses. Depending on the complexity of the changeover, this can take a correspondingly long time and be error-prone. Digital assistance platforms can provide support here. Learn how.

Daniel Grobe

Oct 22, 2021

Latest articles on digital work instructions and checklists

Die Standardisierung von Prozessen ist ein zentraler Faktor für die Effizienz, Qualität und Wettbewerbsfähigkeit produzierender Unternehmen. Wir zeigen Ihnen, wie Sie Ihre Prozesse durch globale Arbeitsanweisungen standardisieren können.

Editha Bertsch

Oct 7, 2024

In modern industrial production, efficiency and quality assurance are two key objectives. Combining work instructions and inspection records is an approach that offers significant advantages in this context. This article highlights the positive effects that result from the integration of these two essential documentation elements.

Editha Bertsch

Aug 23, 2024

Most manufacturing companies have already recognized that there is no alternative to digitizing production. It is therefore all the more surprising that the clipboard has still not been banned from the shopfloor and that operational employees still work with paper-based process descriptions.

Yet digital documentation has invaluable advantages. Easy drag-and-drop creation and customization of digital documentation and the ability to provide multilingual instructions are just two of them. Our blog post sheds light on others.

Editha Bertsch

Aug 18, 2022

Efficient production has never been more difficult, especially when faced with the constant pressure to innovate quickly and deliver ever greater value to customers. Having the right information in the right place at the right time has never been more important. That's why digital manufacturing assembly instructions, as opposed to their paper-based counterparts, play a critical role in today's manufacturing environment.

Digital work instructions help manage increasing product complexity and make your employees' day-to-day work easier. Growing demands for product customization and shortening production cycles are among the biggest challenges in modern manufacturing. At the same time, quality control remains as important as ever, and sacrificing one for the other is neither sustainable nor profitable.

Markus Glotzbach

Feb 18, 2022

Writing work instructions is cumbersome. We understand that. But we would still like to take up the cudgels for them. Comprehensible step-by-step instructions not only help to carry out activities correctly. The creation of work instructions is an underestimated, value-adding process: processes are critically analyzed and further developed in the process. That's why we don't just want to give you tips on how to write really good work instructions. We will show you the potential that writing them holds for industrial companies. Read on to find out how you can leverage this potential. Or, jump straight to the content and style of the perfect work instruction.

Editha Bertsch

Feb 3, 2022

The importance of high-quality work instructions is constantly increasing. In times of a shortage of skilled workers, small batch sizes and varied productions, a precise work instruction is the gold of the 21st century. Find out here how to create a professional work instruction and what you have to pay attention to.

Benjamin Brockmann

Oct 18, 2021

Offering customers a wide range of variants will not be a differentiating feature in perspective, but a standard that must also be taken into account operationally in assembly processes, testing processes and other workflows. As the number of variants increases, a suitable data structure becomes more and more important.

Benjamin Brockmann

Oct 25, 2021

The checklist in production helps to carry out various processes. It supports workers in the maintenance of machines, in the review of quality targets and in the incoming goods inspection. Read more on how to optimize your checklist creation.

Editha Bertsch

Oct 26, 2021

As a specific form of inspection sheet, the check sheet is an established method for evaluating attributive inspections. The quality control check is based on the number of failures, since no measured values for defective parts are available with the static defect card.

Read here how you can make the way from the excel check sheet to a powerful quality tool.

Editha Bertsch

Oct 25, 2021

New employees are often not productive for weeks at the beginning, the training takes a lot of time and personnel resources. To ensure that employees are trained more quickly and can take on tasks independently at an earlier stage, training by means of integrated software is suitable. Self-learning in particular can help to bring employees on board more efficiently.

Editha Bertsch

Oct 21, 2021

Every device, every machine and every system must be tested regularly: whether cordless screwdrivers, ventilation systems or complex production machines. In addition to accurate inspections, the documentation of the test results is also extremely relevant. Digital inspection protocols are the optimal basis for legally compliant documentation. Read more ...

Daniel Grobe

Oct 21, 2021

Latest articles on software and technology

With a Connected Worker Platform, manufacturing companies are creating the basis for connected and digitally supported work on the shopfloor. Manufacturing is thus joining the ranks of company and industry-wide initiatives to position itself globally for the future. Not everything that has been presented and promoted over the past ten years under the banner of "Industry 4.0" has proven to be practical and sensible. At our "Future Manufacturing" event in German language you will find out what will help the industry move forward in practice and what is already a reality today. We will pay particular attention to the potential, but also the limits, of applications based on artificial intelligence (AI).

Markus Glotzbach

Nov 1, 2023

MS Office solutions are a popular choice in the industrial context, for example in production or quality management. Microsoft has stopped supporting Infopath in July 2021. Which software is the best InfoPath alternative?

Benjamin Brockmann

Oct 26, 2021

Every company uses a range of software solutions to support and map its processes. Before introducing new software, companies are often faced with a decision: standard software vs. individual software?

Editha Bertsch

Oct 20, 2021

Increase efficiency and transparency with digital assistance software and drive the digital transformation of your production in a sustainable and integrated way.

Daniel Grobe

Oct 22, 2021