One of the most obvious benefits of paperless manufacturing is the reduction in paper consumption and printing costs. Traditionally, large amounts of paper were used in various departments of a production facility for work instructions, reports, inspection protocols and other documents. This not only led to significant costs, but also to an increased administrative burden to manage, distribute and store the documents.

Another key advantage of paperless manufacturing is that information and data are available in real time, enabling fast and accurate communication between different departments. Previously, physical documents had to be passed around and archived, leading to delays and potential errors. By digitising processes, employees can access the information they need at any time and from any location, which reduces production time and increases responsiveness.

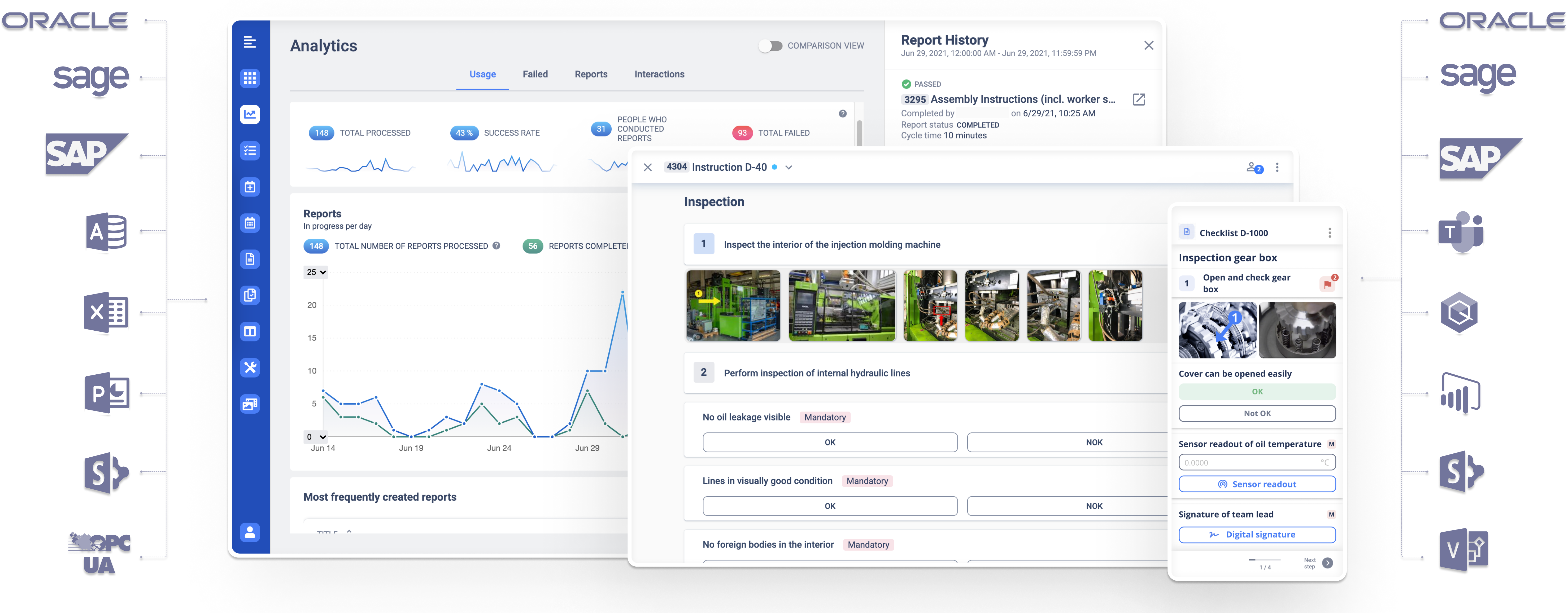

Paperless manufacturing is closely linked to the concept of Industry 4.0, which aims to comprehensively network machines, plants and systems. In a smart factory, these components work together and continuously exchange information to ensure a smooth production process. By integrating paperless manufacturing into a smart factory environment, companies can optimise their production processes and respond flexibly to changing market conditions.

Overall, paperless manufacturing offers many advantages for companies. It enables seamless integration of information and data into production processes, improves efficiency, reduces costs and supports quality assurance. By introducing digital technologies into manufacturing, companies can take a big step towards networked and future-proof production that meets the requirements of modern industry.