Increase machine availability and flexibility with Preventive Maintenance Software

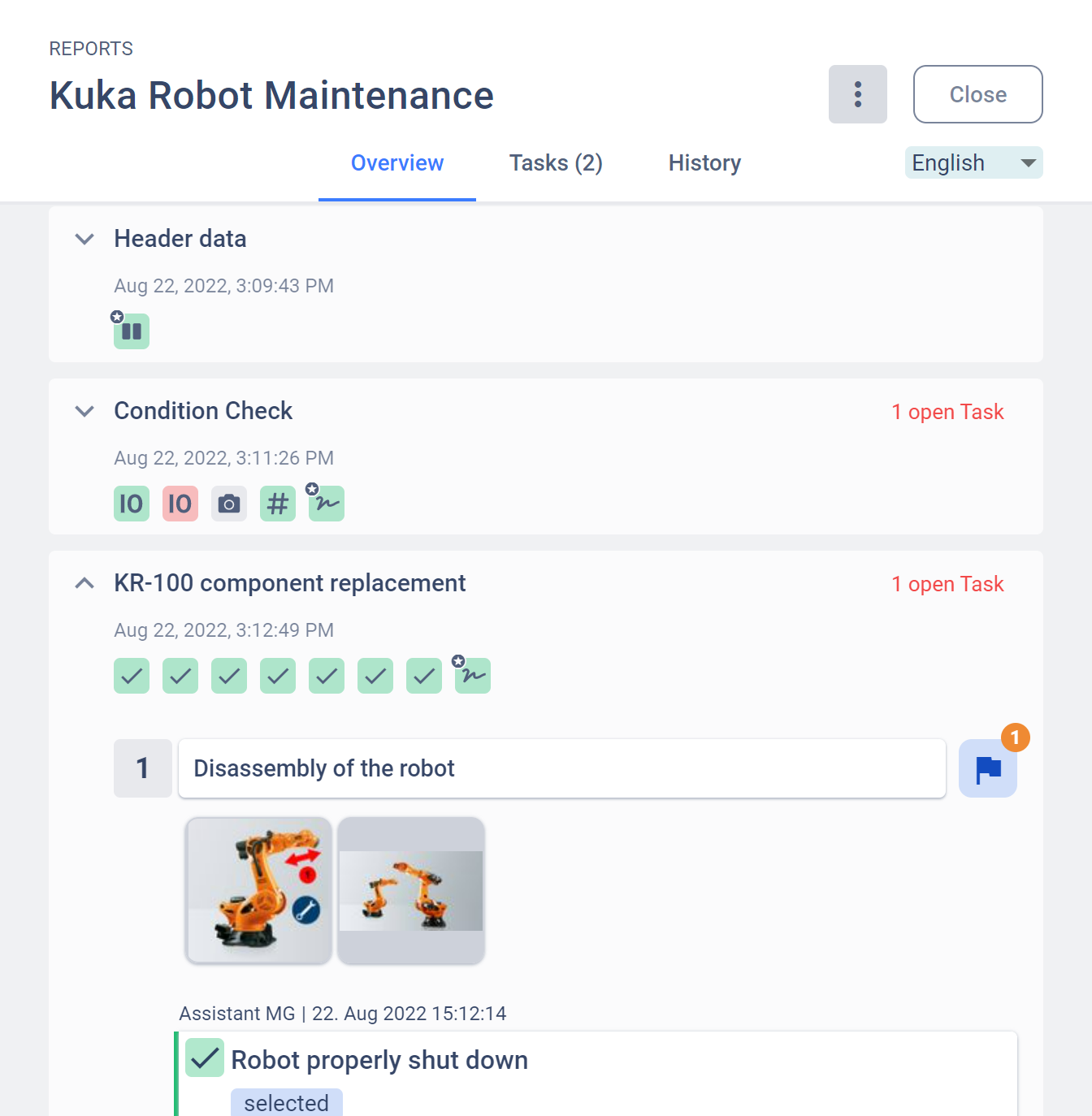

Digital picture- and video-supported maintenance checklists enable your staff to carry out maintenance work more efficiently.

Implement standardized preventive maintenance processes from planning to seamless reporting in one software.

Get started with Preventive Maintenance

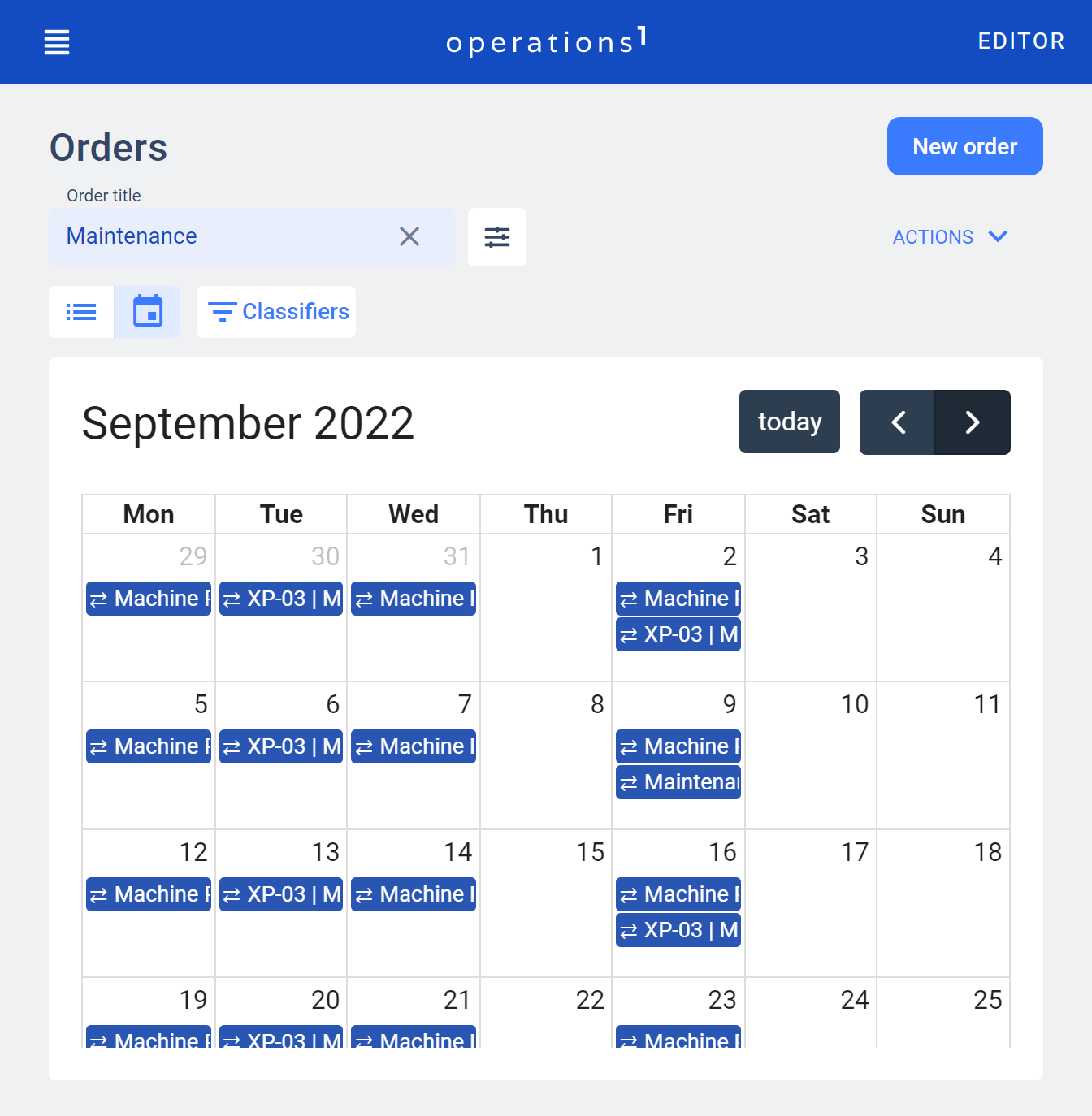

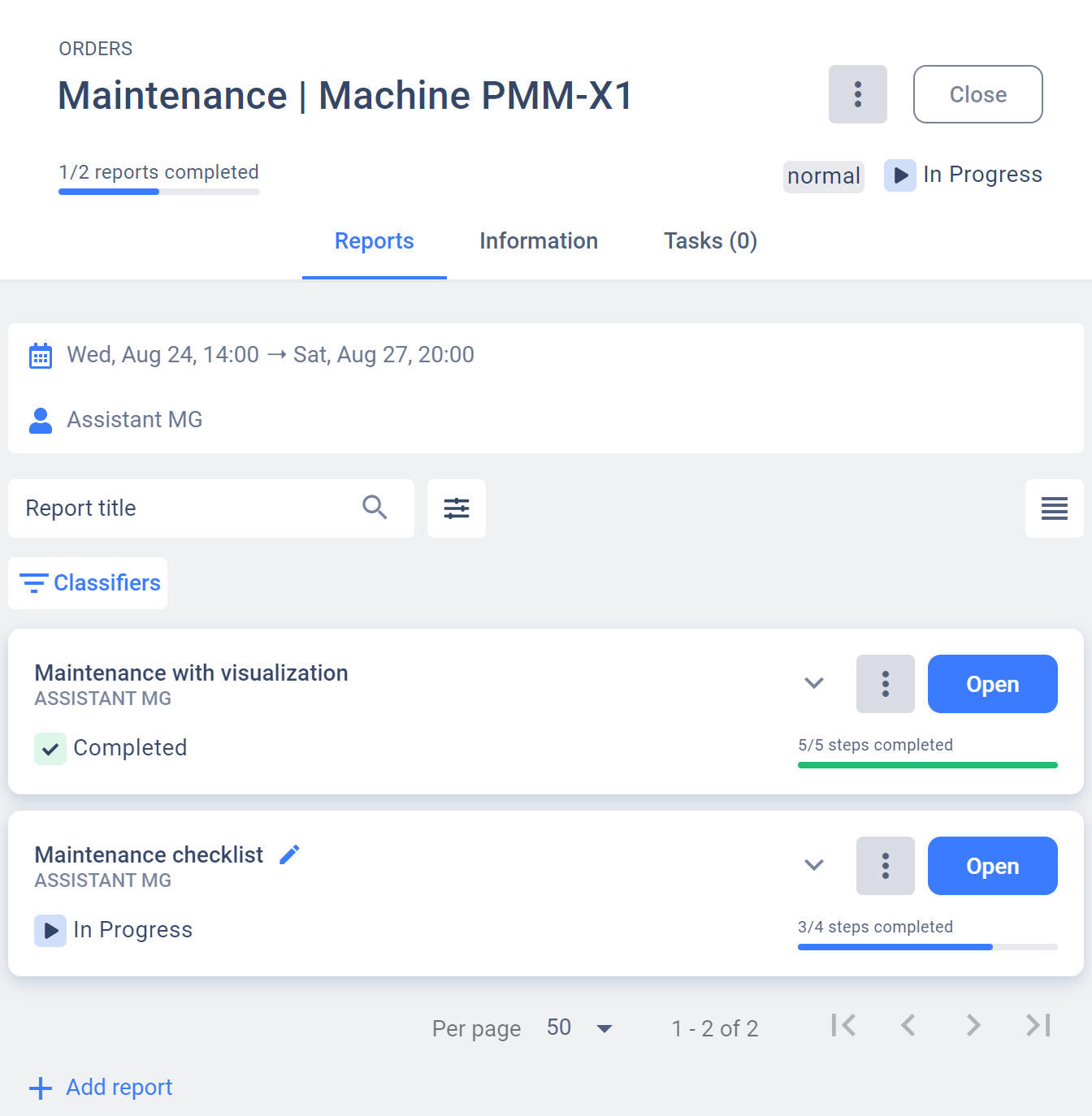

Our connected worker platform allows you to manage maintenance activities paperlessly and easily, while letting your staff perform inspection, maintenance and repair tasks accurately through digital asset-specific checklists.

See how you can digitize your maintenance processes with Operations1

Get to know the software in just 3 minutes

Get an overview of the functionalities and application areas of Operations1.

Digital preventive maintenance: 6 reasons for Opeations1

Why do leading companies in the discrete manufacturing and process industries choose Operations1 to digitize maintenance documentation?

Enormous industry expertise

Our dedicated industry experts at Operations1 work with 100+ leading companies from manufacturing day-to-day and are keen to support you.

Proven RoI

With every client, we jointly identify value drivers and collaborate on realization. We are happy to share our rich experience of successful implementations.

Broad functionality

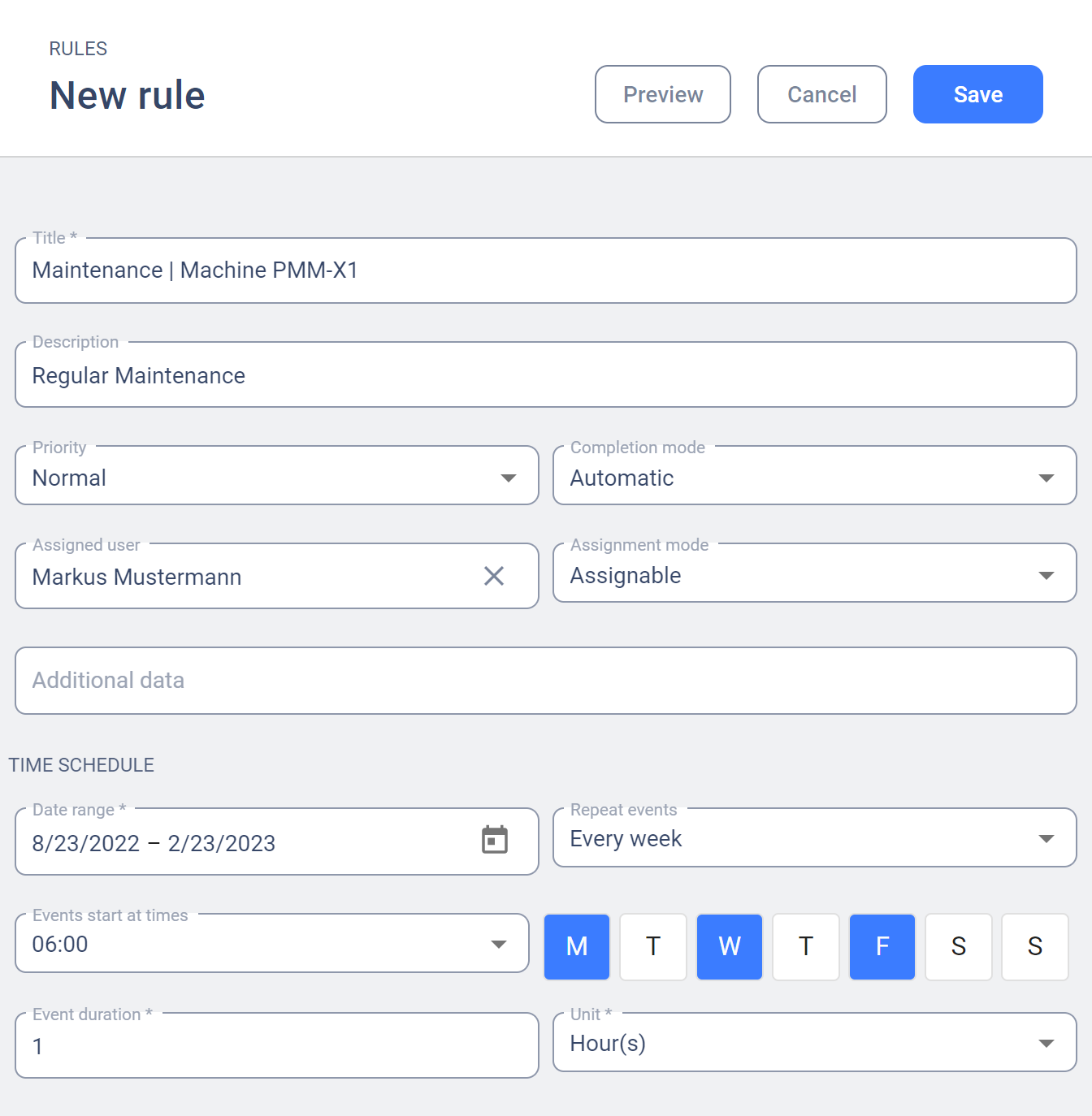

Our comprehensive platform enables you to fully digitize operational processes from planning over execution to analytics.

Easy and risk-free start

Through the SaaS approach, you can start tomorrow without transformation projects and heavy implementation cost. Just get in touch with us.

Great collaboration

We aim to create long-term partnerships with our clients. Our service satisfaction of 99,5% and the splendid customer retention speak for themselves.

High Scalability

Our technical foundation and platform features are made for enterprise customers in order to scale across sites and geographies in an easy way.

Get to know Operations1 in a live demo

We would be happy to show you the functions of Operations1 in an individual live demo and answer your questions.