5S Checklist Software: Conduct audits using an app

Easily create order, clarity and increase productivity in your operations. With Operations1, 5S audits succeed without cumbersome paperwork. Thanks to intuitive creation and evaluation of digital 5S checklists, you can continuously optimize production processes, easily introduce employees to the 5S system and archive audit results in an audit-proof manner.

5S Audit Software for Industry Leaders

Sort (seiri) - Set in Order (seiton) - Shine (seiso) - Standardize (seiketsu) - Self-discipline (shitsuke). Companies use the 5S method to organize order and cleanliness in workplaces. A clean and safe working environment helps to focus on essential production processes. Operations1 supports you in complying with the five steps and makes the use of 5S checklists easy and scalable.

Advantages of digital 5S checklists for your production operation

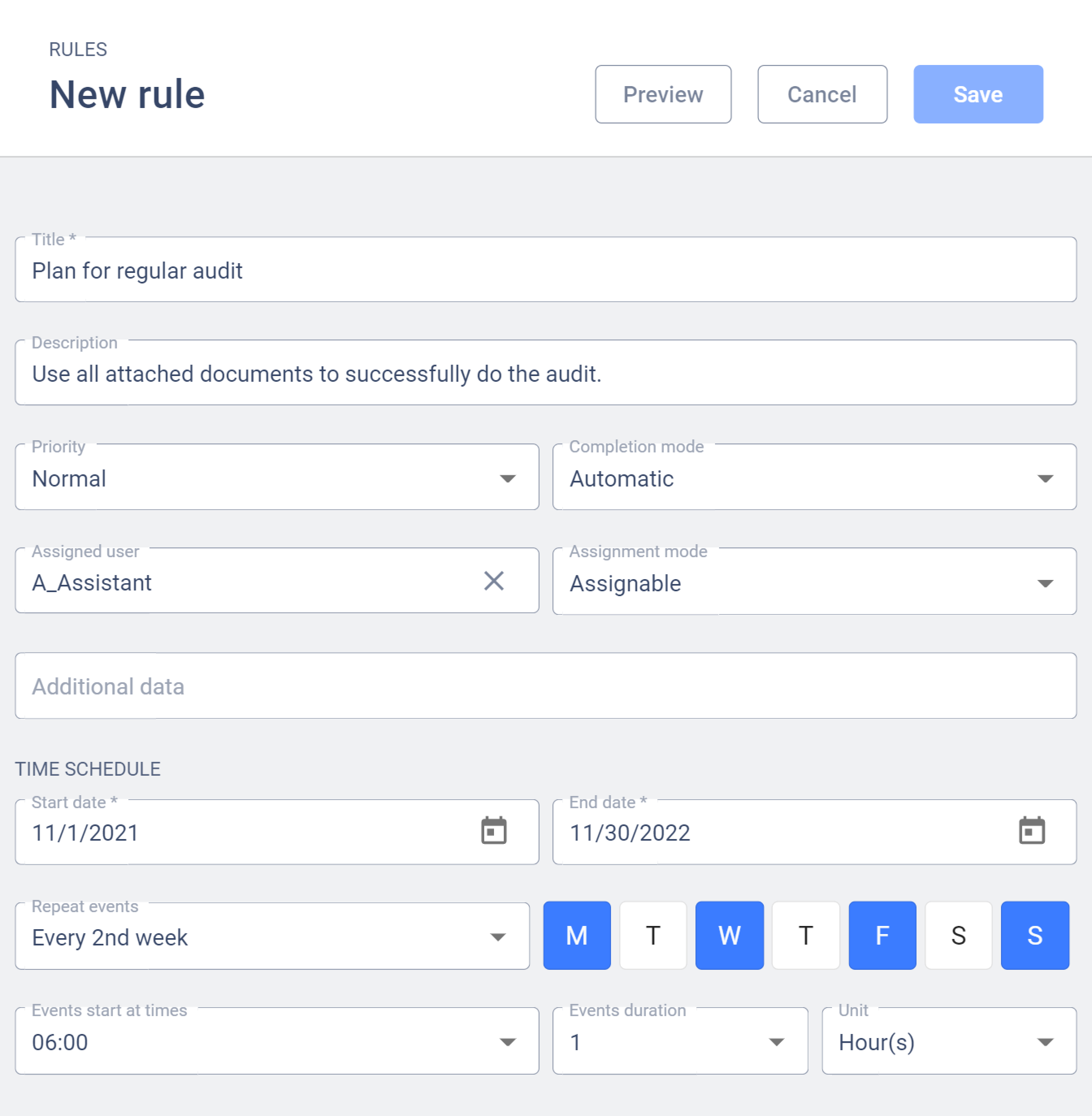

5S Audit planning

Easily create multilingual 5S audits and assign them to your employees. Schedule audit intervals and track progress live in the dashboard.

Multiple interactions

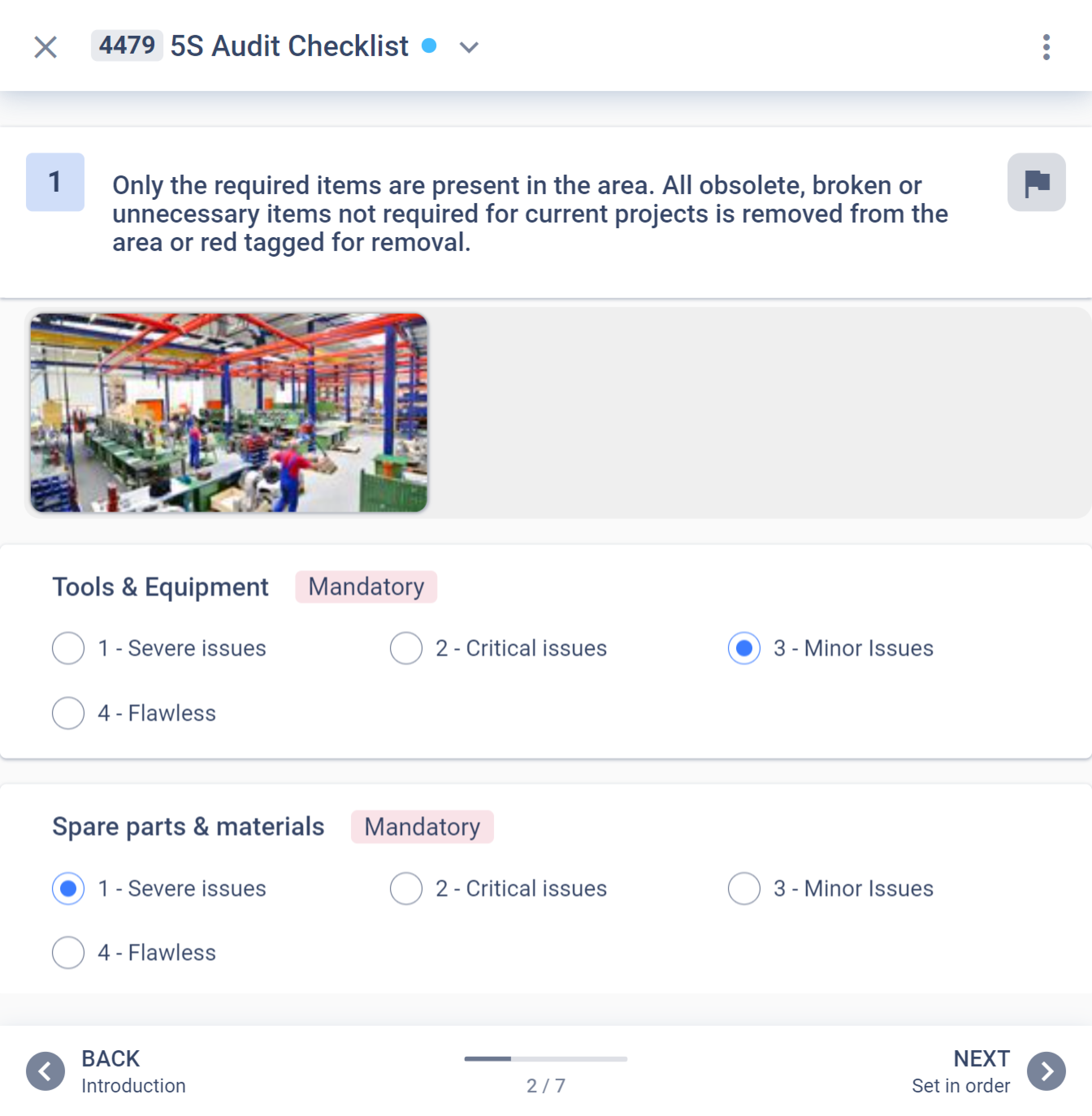

Choose from checks, value comparisons or OK/nOK queries and drag and drop to create the perfect 5S audits for your individual use case.

Mobile 5S Audits

Fill out digital 5S audit checklists directly on your tablet or smartphone during the walk-through. The collected data does not have to be transferred manually afterwards.

Image and video

Make the 5S system easily understandable and accessible to your employees with image and video integration. Independent of language and qualification.

Findings photos

Document and store incidents such as improper tool storage or unclean workstations directly in the software.

Incident management

Assign findings such as material waste from your 5S audits directly to individual employees and track their processing in real time.

Signature field

Confirm audit execution directly on the tablet or smartphone with a digital signature. Date and auditor are automatically recorded and saved.

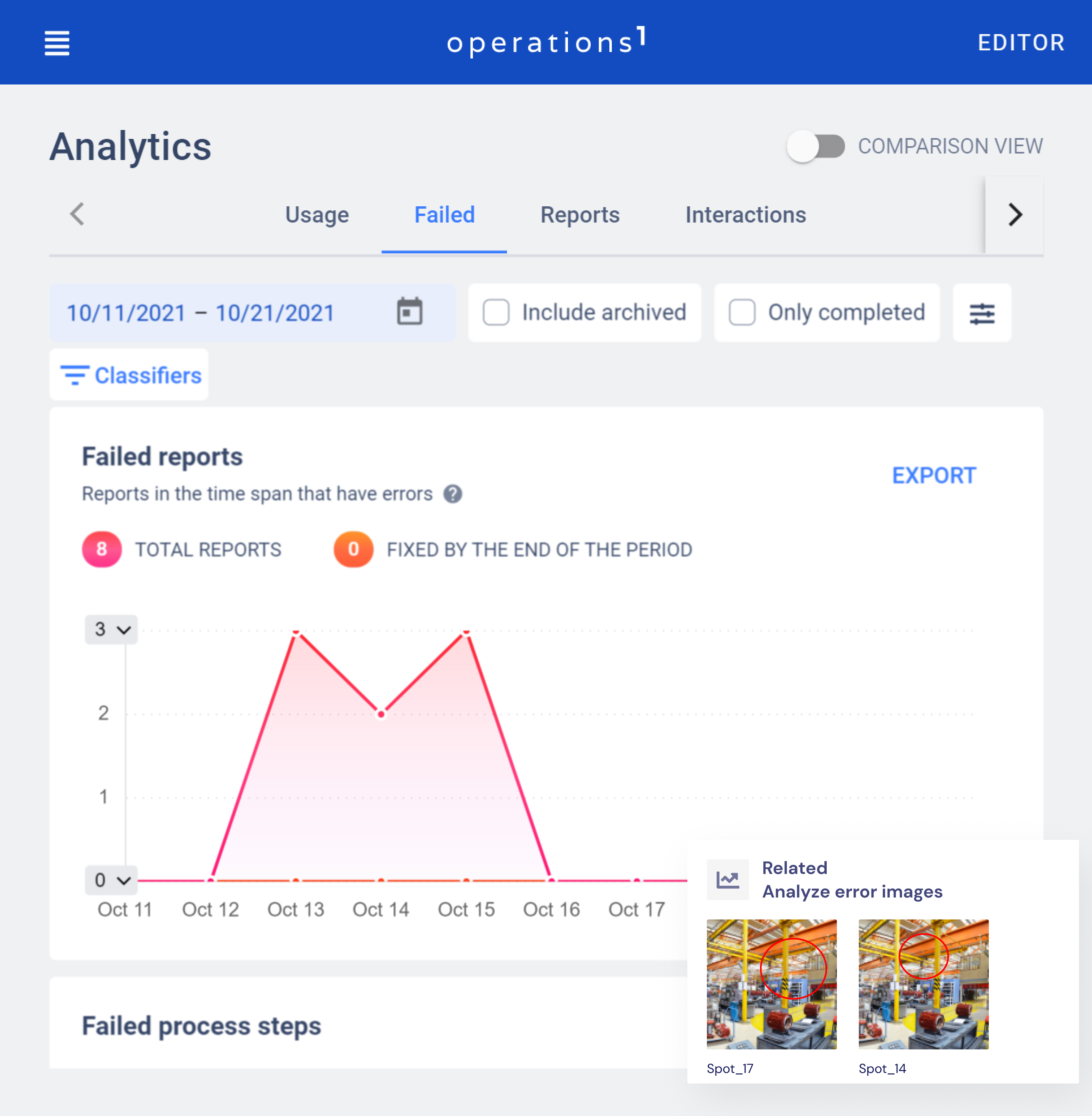

Reports

Create automated reports, archive them in an audit-proof manner and analyze the collected data in Operations1 or in third-party systems.

Book a personal demo

Get in touch with our product experts to find out how you can benefit from Operations1.