Create manufacturing and assembly instructions easily with software

Digital support for your employees reinvented. Create step-by-step manufacturing and assembly instructions with our Operations1 software. Intuitive, collaborative and evaluable.

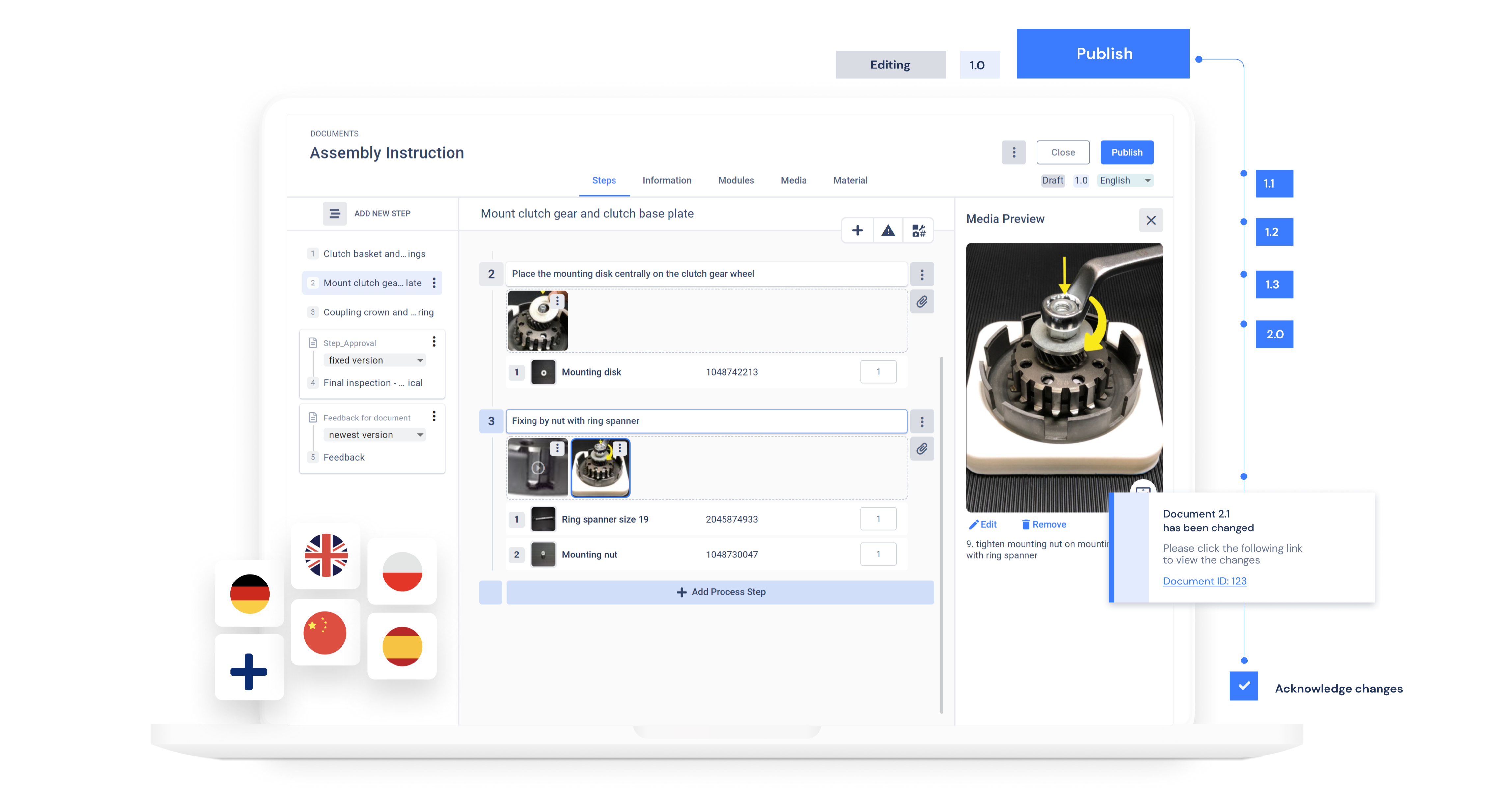

Create manufacturing and assembly instructions

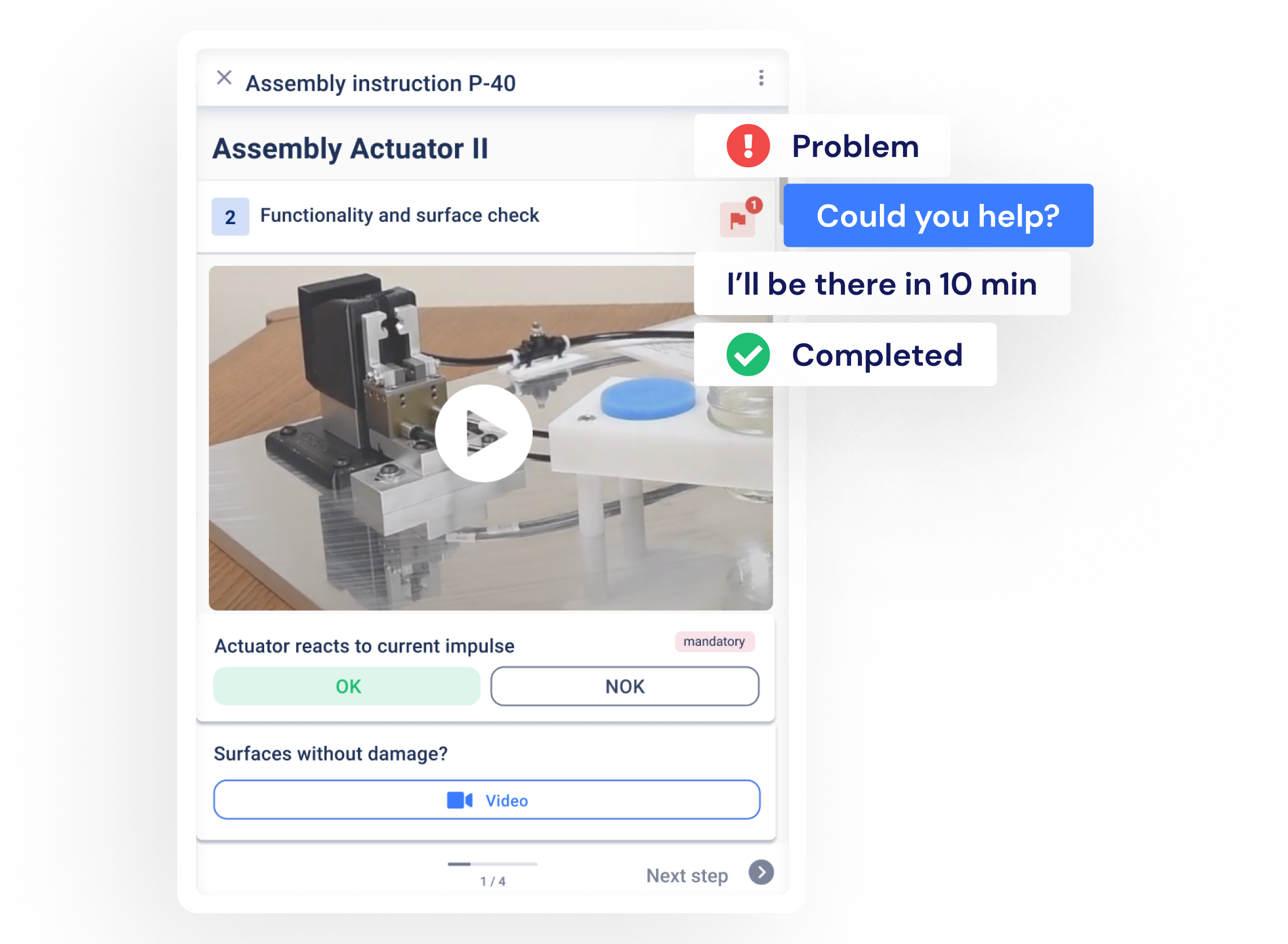

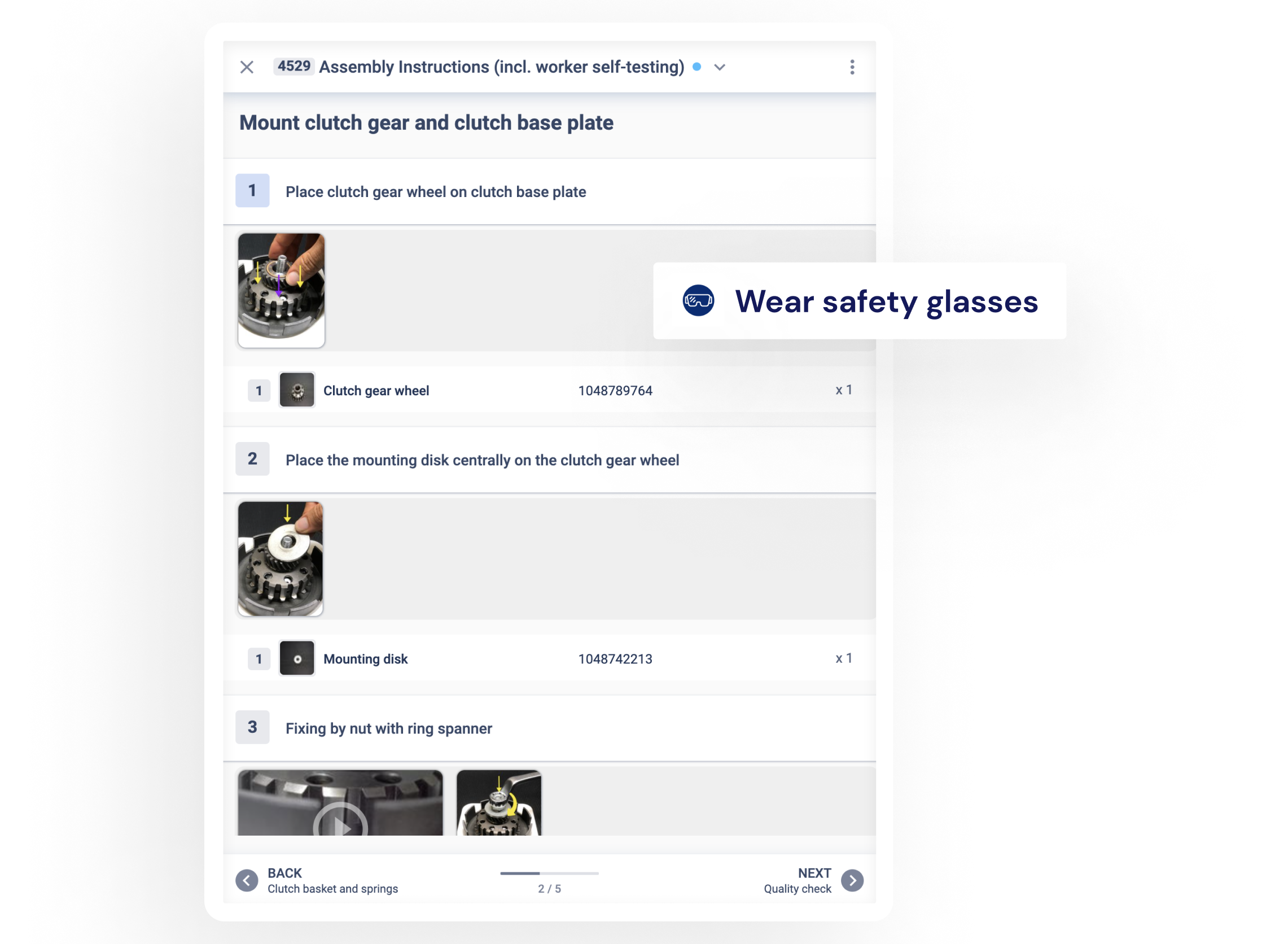

Create manufacturing and assembly instructions directly in development or during pilot production of a new product. With the smartphone or tablet, you can capture images and videos directly during the process. In the Creator you can add textual descriptions and interactions such as OK/NOK tests.

Advantages of automated assembly instructions

Thanks to intuitive user guidance, you create digital assembly instructions quickly and efficiently. Automated versioning ensures that your employees always have the latest version. Multilingualism as well as text-reduced, media-supported work instructions support your employees in living processes. Regardless of location and qualification.

Multilingualism

Provide the software and instructions in all common languages of the world

Images and videos

Include videos and photos directly in your assembly instructions for visual support

Media editor

Edit images directly in Operations1 software to highlight specifics in the manufacturing process

Modular structure

Create and edit recurring elements at a central point of truth

Drag and drop

Simplify the creation of your manufacturing instructions thanks to intuitive user interface

Change notifications

Inform employees about changes in the assembly instructions simply by means of notifications

Material & Tools

Store materials and tools visually in your work instructions

Production orders

Plan your orders in Operations1 or transfer them from ME and ERP systems

Integrated checkpoints

Perform digitally evaluable worker self-checks after specific assembly steps

Enable collaboration and improve efficiencies

With Operations1, your employees and teams work simultaneously on the same production orders and interact with the work progress of their team colleagues

Tools and instruments connection

Connect tools, measuring instruments and machines with the cioplenu application. Integrate measurement results or machine data during operations directly into checklists and work instructions.

Provide assembly instructions intelligently

Automatically offer your employees only the work instructions that are relevant to them. The current versions can be called up via tablet and smartphone or stationary at terminals. Use barcode or QR scans or directly the order data from your ERP.

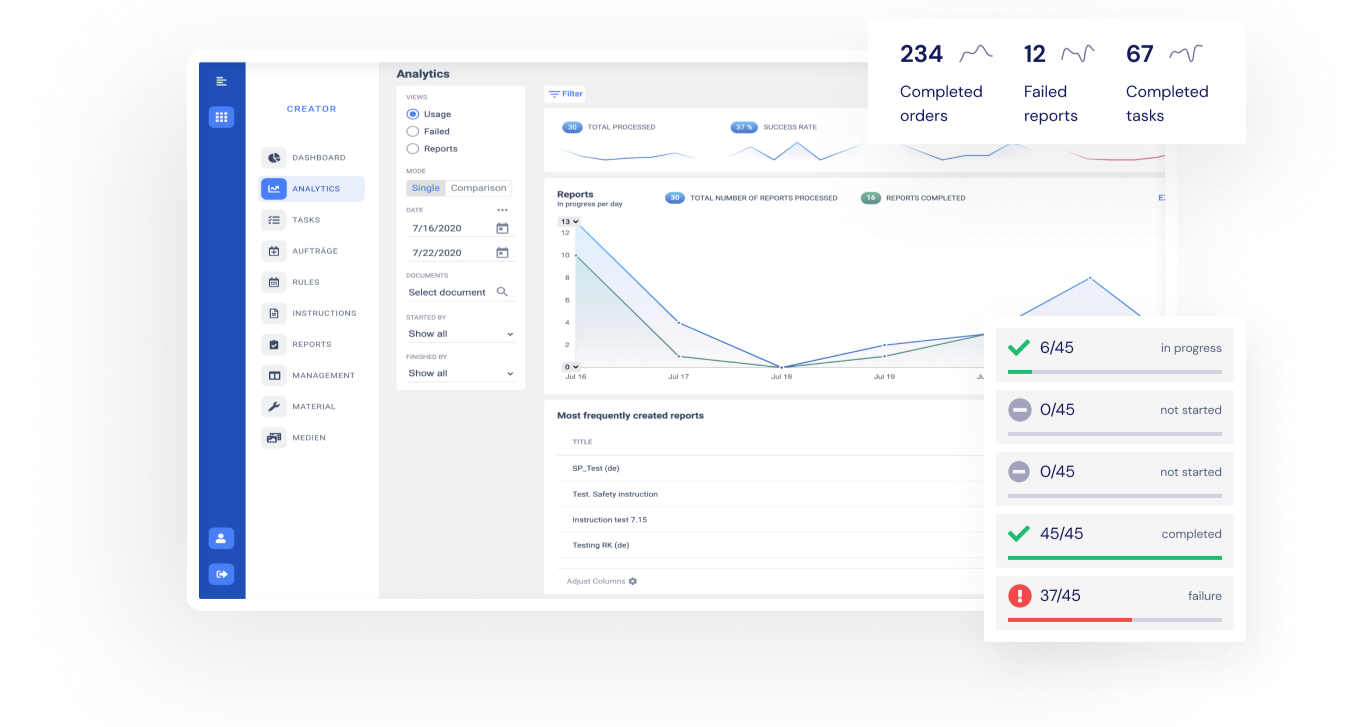

Analyze and Optimize

Analyze your activities and enter changes into your work instructions and checklists without much effort. The Operations1 platform takes care of the automatic versioning for you. Via a defined approval process, your employees receive the updated documents immediately.

Connection to ME and ERP systems

Share production-relevant information directly with your ME or ERP system. Trigger the opening of work instructions via RFID or from the MES. User interactions can be transferred in real-time to production-relevant systems.

Request your live demo today

Get to know Operations1 in a live demo

We would be happy to show you the functions of Operations1 in an individual live demo and answer your questions.