Webinar recap: Successfully implementing standardized processes with multilingual work instructions

Standardized processes – understandable worldwide. Multilingual, digital work instructions help manufacturing companies standardize processes globally, secure knowledge, and train new employees more quickly. This makes operational excellence a reality – across locations, languages, and cultures. Multilingual, digital work instructions help manufacturing companies standardize processes globally, secure knowledge, and train new employees more quickly. This makes operational excellence a reality – across locations and languages. In this webinar recap, you will learn how companies such as Liebherr-Verzahntechnik GmbH have implemented their processes using a digital platform such as Operations1.

What it's about

This article shows how companies such as Liebherr have been able to standardize their production processes internationally through the use of multilingual, digital work instructions efficiently, comprehensibly, and independently of language or personnel barriers. You will learn why traditional training methods are increasingly reaching their limits, how digital platforms can help, and what results companies are achieving with them.

The reality of production: global, complex, and under pressure

Globalization, a shortage of skilled workers, and growing product diversity pose major challenges for manufacturing companies. In Germany, the number of applicants for apprenticeships has been declining for years, while at the same time production lines are having to be relocated to other countries. In addition, many new employees speak neither German nor English and are expected to be immediately ready for work on the shop floor.

If these people are absent whether due to illness or vacation or even leave the company due to retirement or a job change, this can have a significant impact on quality, productivity, and competitive advantages. This dependency makes companies vulnerable both in day-to-day business and in crisis situations.

“We have many international locations. It is very important to ensure that every location builds the machines in the same way and that the quality remains the same.” Thomas Unmuth, Production Manager at Liebherr-Verzahntechnik GmbH

The Solution: clear digital instructions for everyone, in every language

Localization: Same processes, different contexts

Work instructions must remain consistent in terms of content, but must be adapted visually, linguistically, and to local conditions. This means the same process steps, but communicated differently depending on the location.

Digitization: Fast, automated, scalable

With digital solutions such as Operations1, you can:

Automatically import existing work instructions (Word, Excel, PowerPoint, PDF)

Prepare them in multiple languages with AI-supported translation

Provide content visually, interactively, and in a version-secure manner

These instructions can be quickly optimized at any time and made available to shop floor employees globally in the latest version.

Why It Works: Documented knowledge instead of knowledge stored in your head

Many companies often only realize their dependence on individual key personnel when it is too late – for example, when experienced employees fall ill, go on vacation, or retire. The classic master-apprentice principle is well established, but it is difficult to scale, labor-intensive, and prone to errors. What is missing is a solution that not only secures knowledge but also makes it actively usable regardless of language, location, or prior knowledge.

Digital, multilingual work instructions close this gap. They transform experiential knowledge into clear, easy-to-understand process instructions that are accessible to everyone – on the workstation screen or on a mobile tablet.

The advantages are obvious:

New employees find their feet more quickly – even without prior knowledge.

Training becomes more efficient, structured, and stress-free.

Knowledge remains within the company – even when skilled workers leave.

Processes are auditable and documented in a traceable manner at all times.

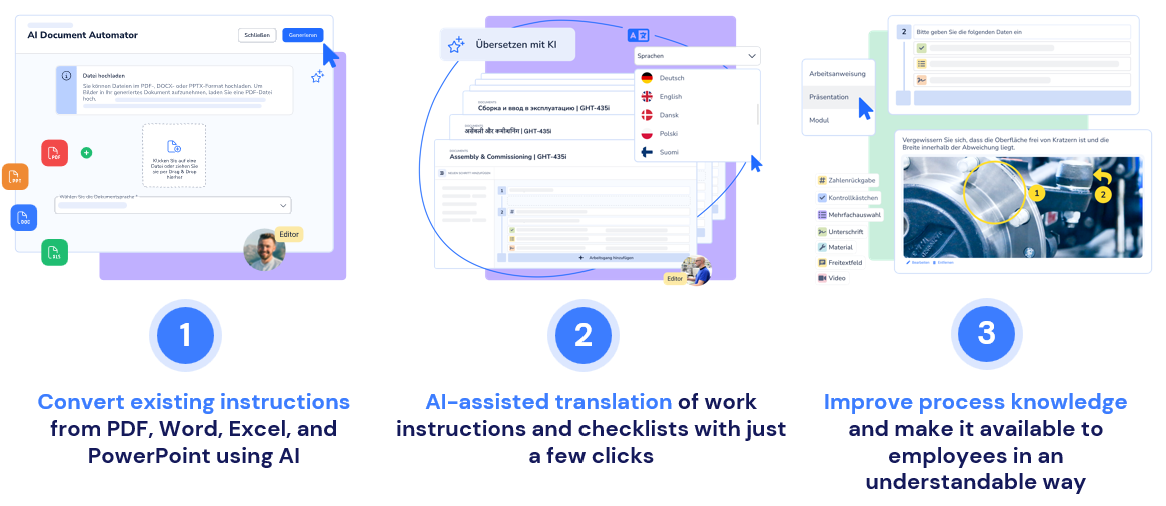

The Operations1 software solution is a good example of how this can be implemented. The process knowledge internationalization process is carried out in three simple steps:

1. Transfer existing instructions

Existing documents (e.g., PDF, Word, Excel, PowerPoint) are automatically imported using AI and converted into a digital structure.

2. AI-supported translation

Work instructions and checklists are translated into different languages at the touch of a button – including technically correct terms and cultural nuances.

3. Make it understandable

The digitized instructions are visually enhanced, e.g., with images, videos, checkboxes, or input fields, and made ready for use directly on the shop floor. This transforms fragmented, language-dependent knowledge into a clear, internationally applicable standard. Employees worldwide understand exactly what to do, and companies ensure maximum quality and efficiency.

Case study: Liebherr-Verzahntechnik GmbH

Liebherr-Verzahntechnik GmbH faced the challenge of relocating production lines to countries with more skilled workers available without compromising on quality, speed, or efficiency. The traditional method of laboriously training new employees on a one-to-one basis was too slow and unsustainable.

Results achieved through digital, multilingual work instructions:

Previously: 3 years relocation time - with Operations1: 1 year through digitalized training

Previously: 5 trainers for 5 temporary workers – with Operations1: 1 trainer supervises 5 at the same time

Previously: Time-consuming training – with Operations1: −70% effort thanks to intuitive documents

Previously: Dependence on head knowledge – with Operations1: Structured knowledge transfer

“Operations1 is easy to use and is very well accepted by the workers. In addition, its multilingual capability enables us to communicate clearly with our employees regardless of their country of origin. These were decisive factors for us.” Thomas Unmuth, Production Manager at Liebherr-Verzahntechnik GmbH

Standardized processes as a competitive advantage

The advantages of standardized, multilingual work instructions go far beyond training:

Quality control All locations work with the same reference

Audit security Every step is documented and traceable

Flexibility New plants can be ramped up more quickly

Employer branding Modern training retains skilled workers

Relief for experienced employees They are no longer used as “gap fillers” in training, but can be deployed productively

Conclusion: Why multilingualism is the key to global standardization

Standardization only works if everyone involved understands the same processes—both in terms of content and language. With digital, multilingual work instructions, knowledge becomes a resource that can be used worldwide. Companies that invest in such solutions early on are not only more efficient, but also more robust, flexible, and attractive to new skilled workers. They focus on clarity instead of guesswork, on clearly structured processes instead of arbitrariness in production, and thus secure a real competitive advantage in the global marketplace.

Now is the right time for digital work instructions!

Couldn't attend the webinar? Simply fill out the form and you will be taken to the complete webinar recording.

Anna-Karina Dawkins

Anna-Karina Dawkins is Team Lead Marketing at Operations1 and is your contact for press, social media and events. Before joining Operations1, Anna worked in marketing at SimPlan AG, a simulation service provider. Prior to that, Anna discovered her passion for marketing at Deutsche Tele Medien GmbH and while employed there, she completed her Bachelor in Business Administration at FOM in Frankfurt.