What it's about

In the following top 5 list, you can read which concrete advantages digital assistance software can offer you and your employees.

Production employees at the center of the use of assistance systems

In order to carry out the digital transformation of your production in a sustainable and integrated way, the resource of personnel, but above all the human being itself, should always be the focus of all strategies, especially in industrial companies. Because know-how and a lot of work cannot be done by robots or machines. This will not change for many specific areas in the future. This ensures that digitization will not destroy jobs – but can definitely transform and improve many. By opting for a sustainable concept for your digital production, you make your company ready for the future and ensure that you continue to work profitably tomorrow. In the following top 5 list, you can read which concrete advantages digital assistance software can offer you and your employees.

1. Relieve your employees

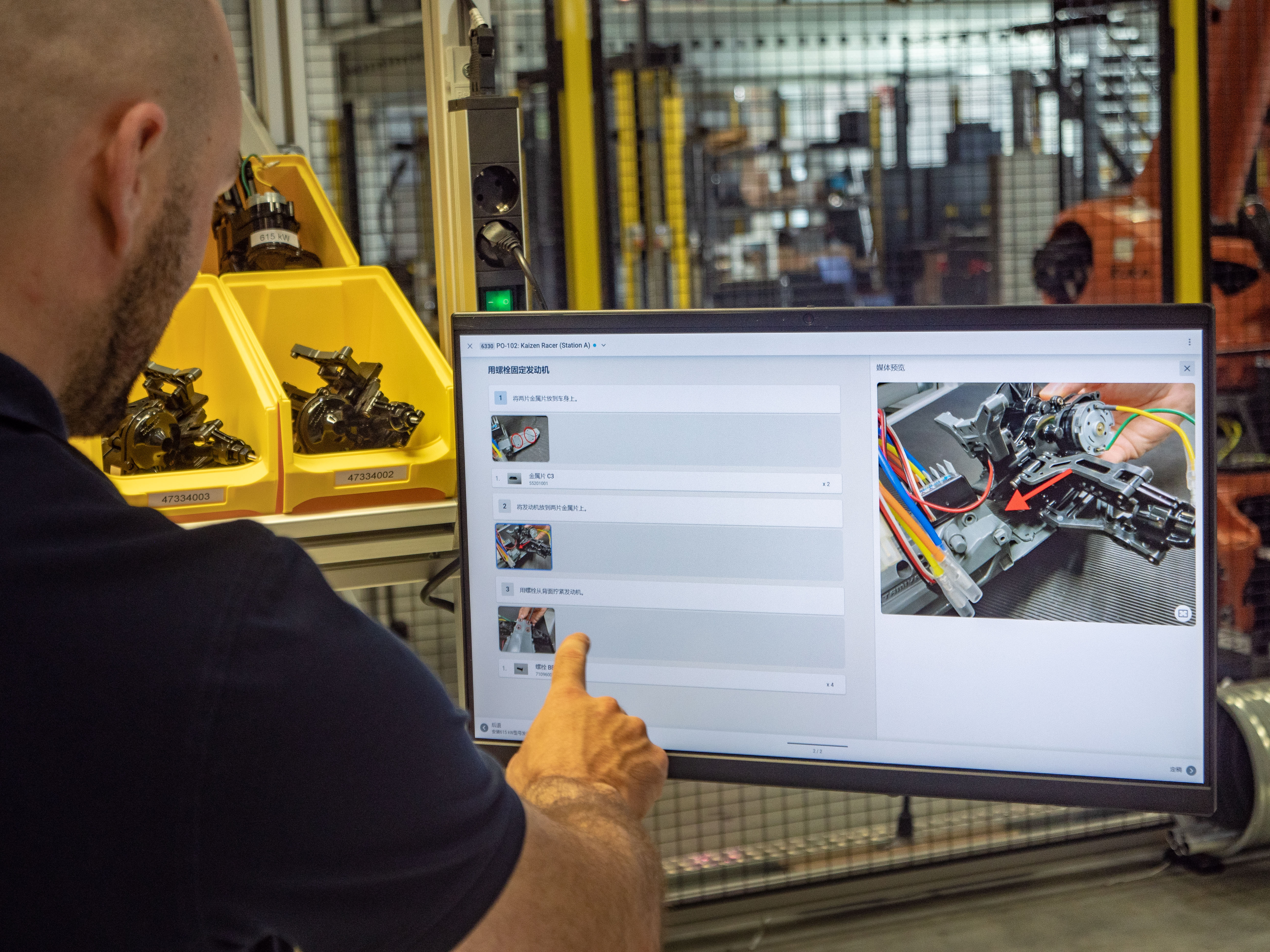

The productions of industrial companies involve numerous tasks that require in-depth specialist knowledge. From the assembly and/or the manufacturing process of the own products over the enterprise resource planning system up to the maintenance of production machines and plants and many more. Digital work instructions with integrated checklists help your employees to perform tasks correctly, to mark completed work steps directly and visibly as such and to keep track of upcoming activities. The digital work instruction enables the employee to perform far more tasks than before. They are guided step by step through the instructions using images, video and text and have comprehensive access to all the knowledge they need. Targeted checklists can be used, for example, during machine maintenance or in production to ensure that no work step is forgotten and that the production management can directly view feedback on the current status and progress.

2. Reduce training times

You can create and edit digital work instructions with photos, videos or pictograms according to the needs of your employees. With the help of software, even unskilled workers can teach themselves a lot of work and look at the description a second or third time. In this way, you save the valuable time of your experienced production staff. They can focus on your actual productive activities. The new employees get into productive operation much faster thanks to the detailed instructions and are practically ready from day one to create value.

3. Optimize product quality

Digital work instructions ensure that the quality of your products increases. Employees have permanent access to the required information, which they can call up directly at their workplace with just a few clicks. They no longer have to walk to remote terminals or search for the right documentation in paper folders, but can find what they are looking for right away. The inhibition threshold to obtain information decreases, because information is no longer associated with effort, but can be retrieved on mobile devices or your own PC. Your product quality will benefit because failures will be permanently and consistently avoided.

4. Shorten changeover times

Changeover times were previously unproductive hours, which, of course, you still had to pay your employees for? With digital work instructions, you can easily integrate non-expert employees into the changeover process and even save one or two service providers.

5. Increase the efficiency of the entire production process

Investing in an integrated, digital assistance platform will pay off for you as you invest in the skills and motivation of your employees, in the quality of your products and in streamlining your processes. And you also make your production paperless, which brings further advantages such as environmental protection and more space due to filing cabinets that have become superfluous. All this leads to an increase in the efficiency of your production all by itself. Fewer errors mean fewer rejects and fewer customer complaints. Reduced training times and the elimination of expensive training personnel allow you to make the most of your human capital. Employees can quickly acquire many more skills that they would be denied without access to relevant information.

Conclusion

All this proves once again that information is the gold of the 21st century. With the appropriate digital worker assistance system or worker information system, companies cleverly bring information together and make it intelligently available to their workforce.

Work Instruction 4.0

With digital work instructions and checklists, you increase efficiency and make better decisions. Read in our whitepaper how our software solution can help you!

Daniel Grobe

Daniel Grobe (M. Sc., Management & Technology) founds cioplenu GmbH in 2017 together with Benjamin Brockmann (also M. Sc., Management & Technology). The founders develop the software solution on the basis of various practical projects, including at the Fraunhofer Institute, and their experience in industry, auditing and management consulting. Daniel Grobe is a Junior Board Member of bayme vbm and has already worked for companies such as KPMG and Continental.