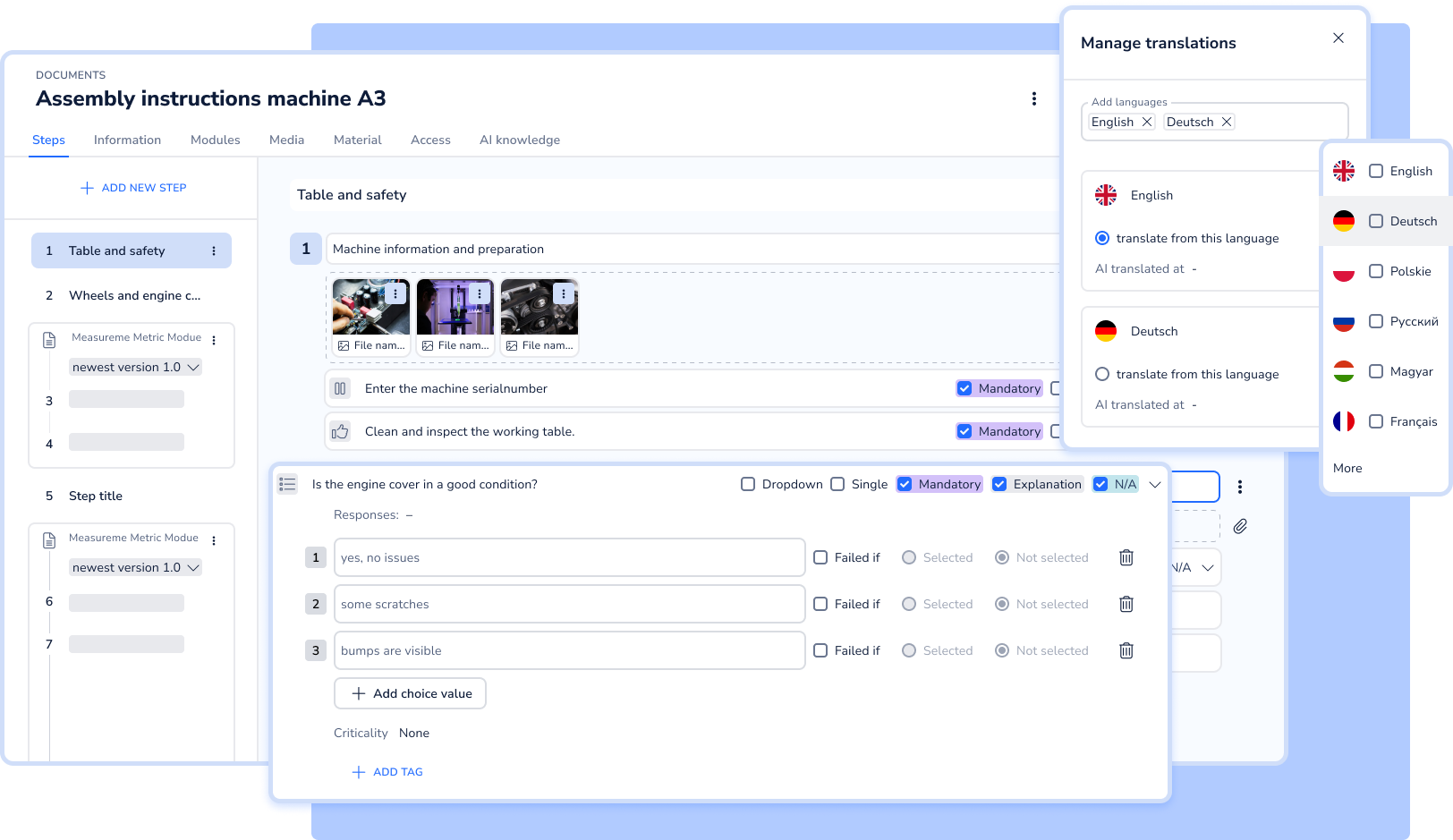

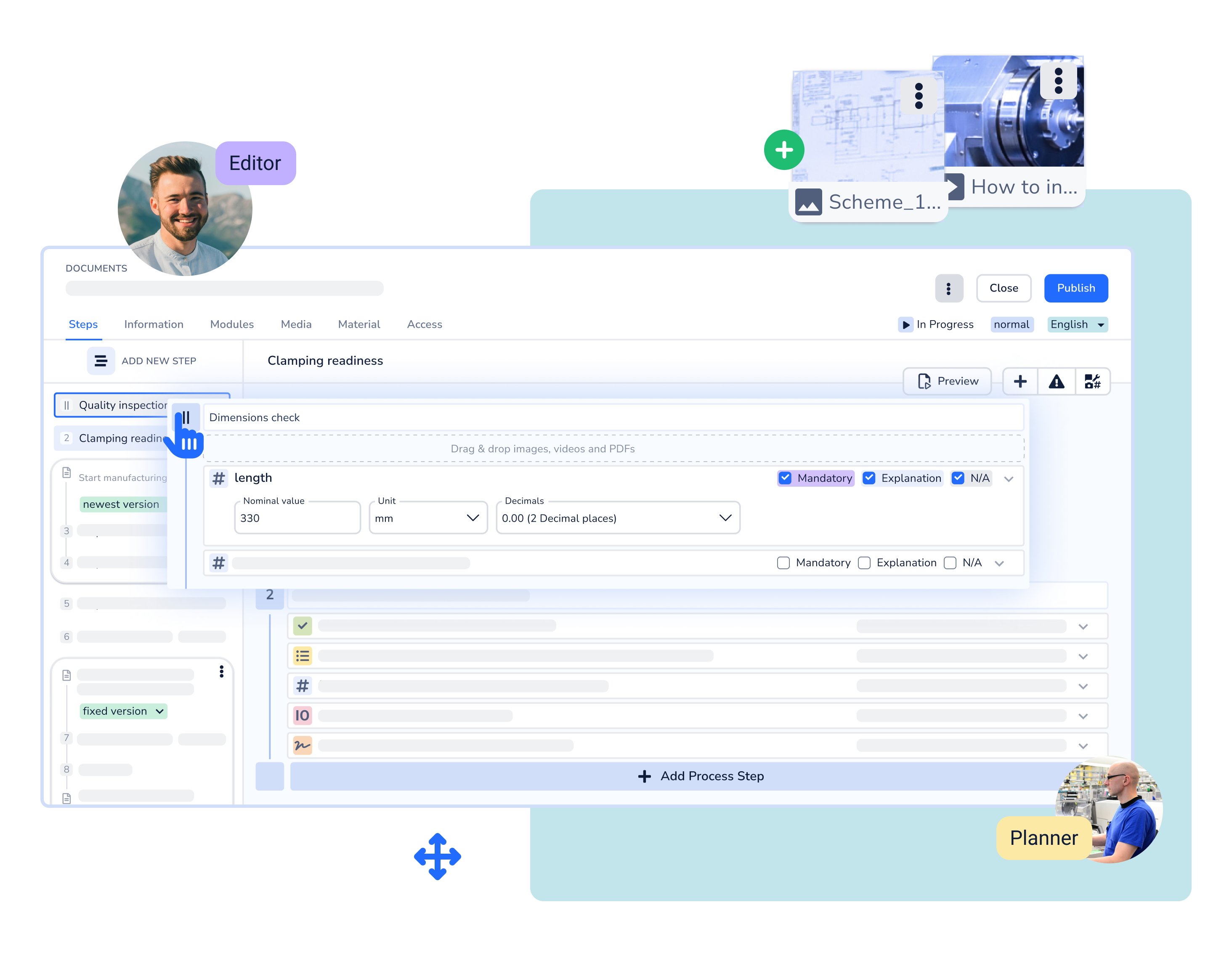

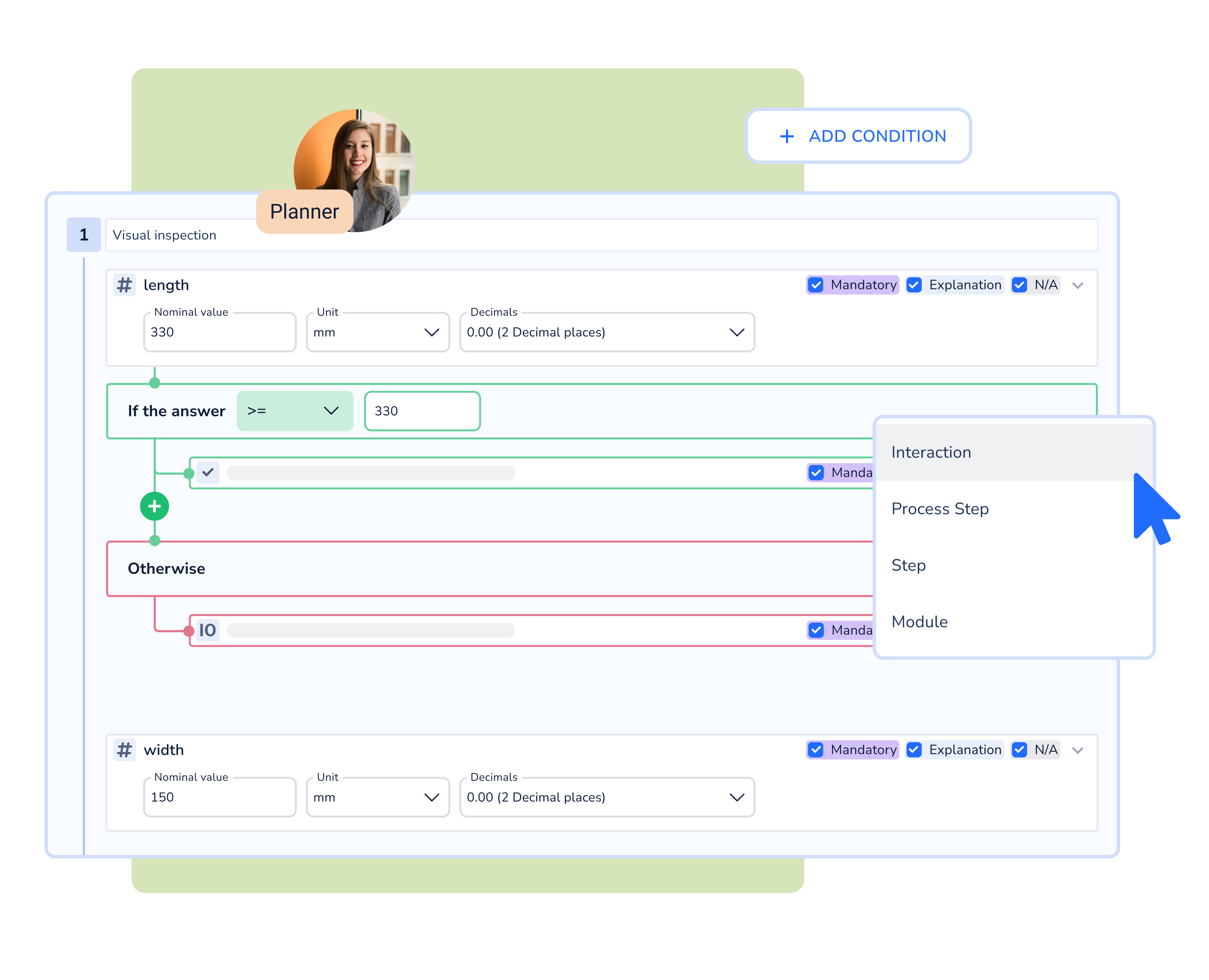

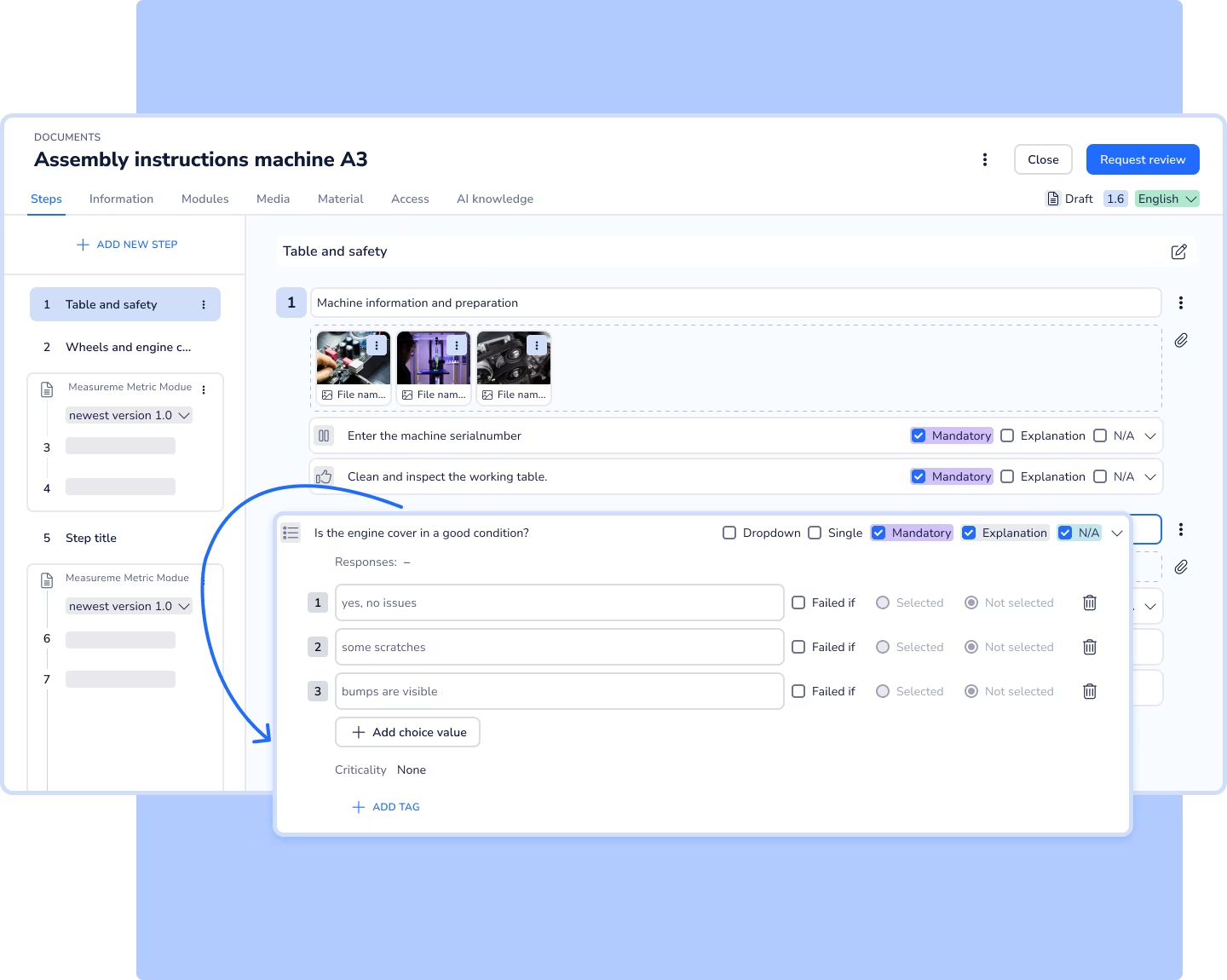

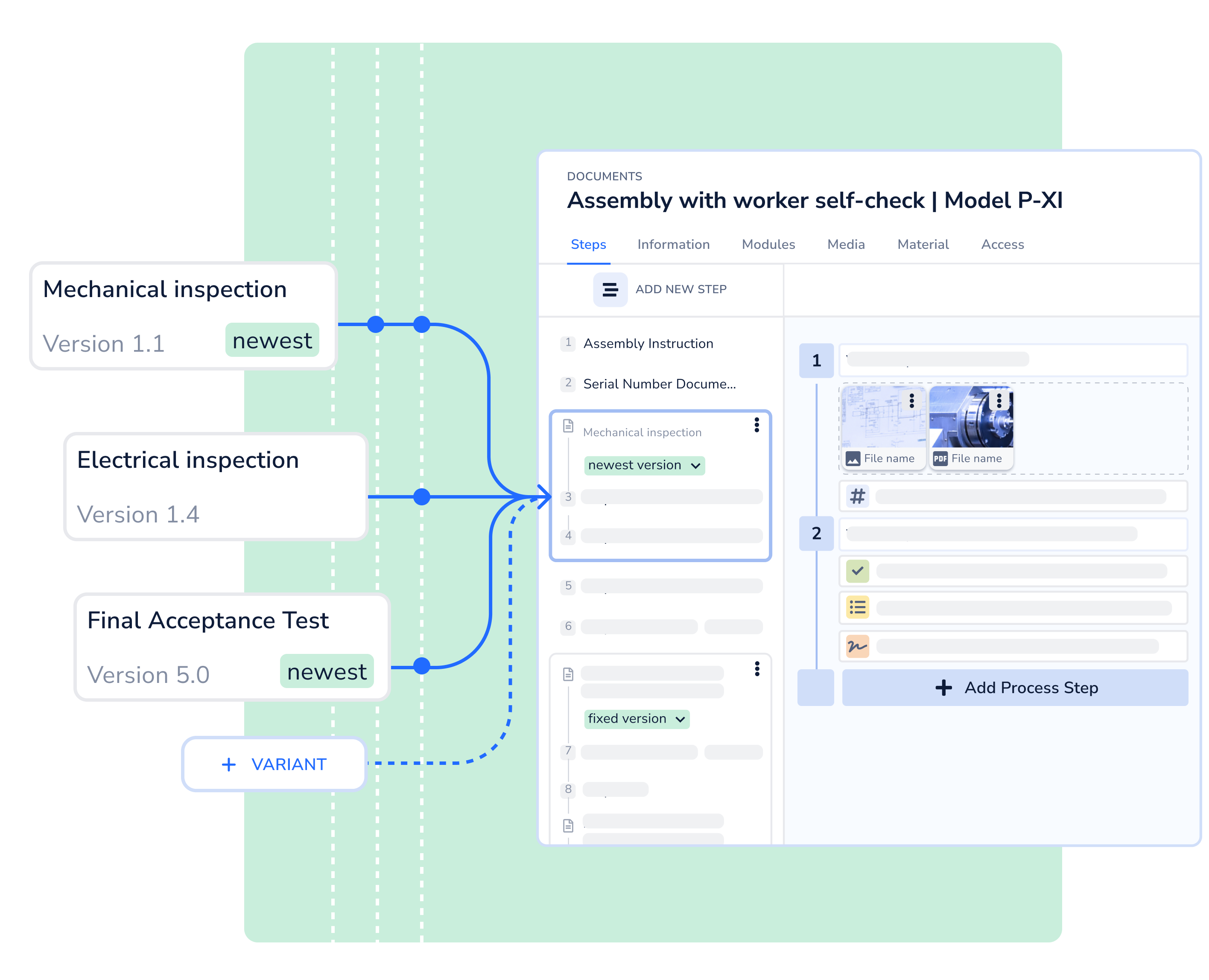

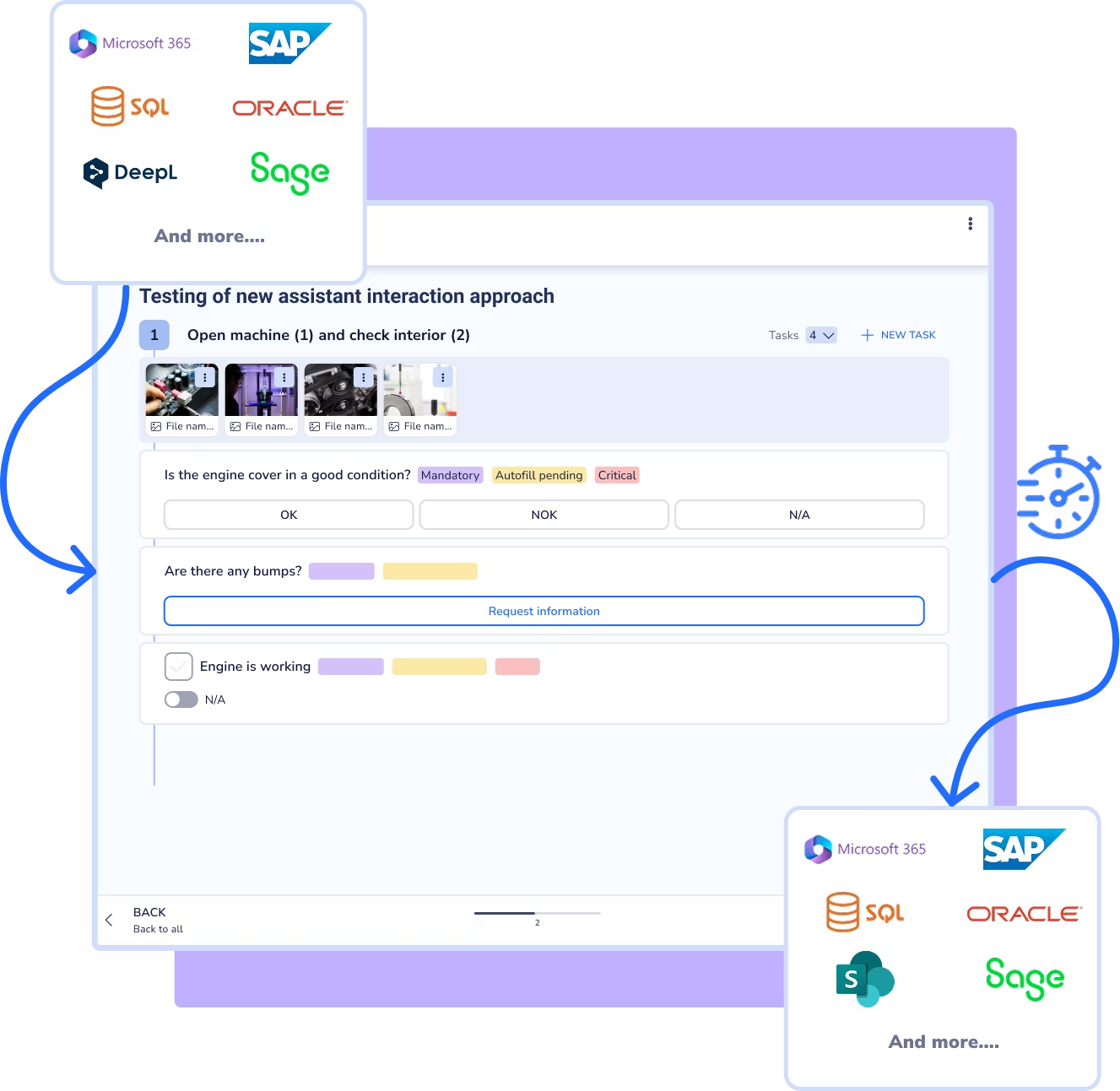

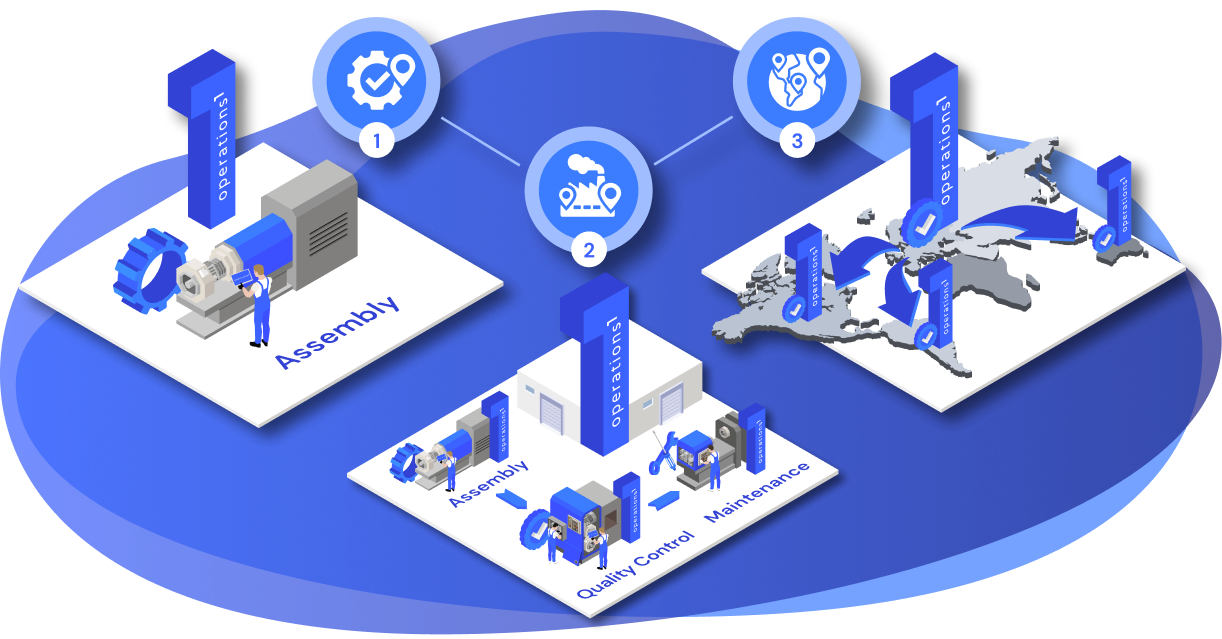

Digital work instructions are created by transferring analog or static content into a structured, interactive software solution. In Operations1, creation is done using a no-code drag-and-drop editor that allows work steps to be structured according to process, product, or equipment logic.

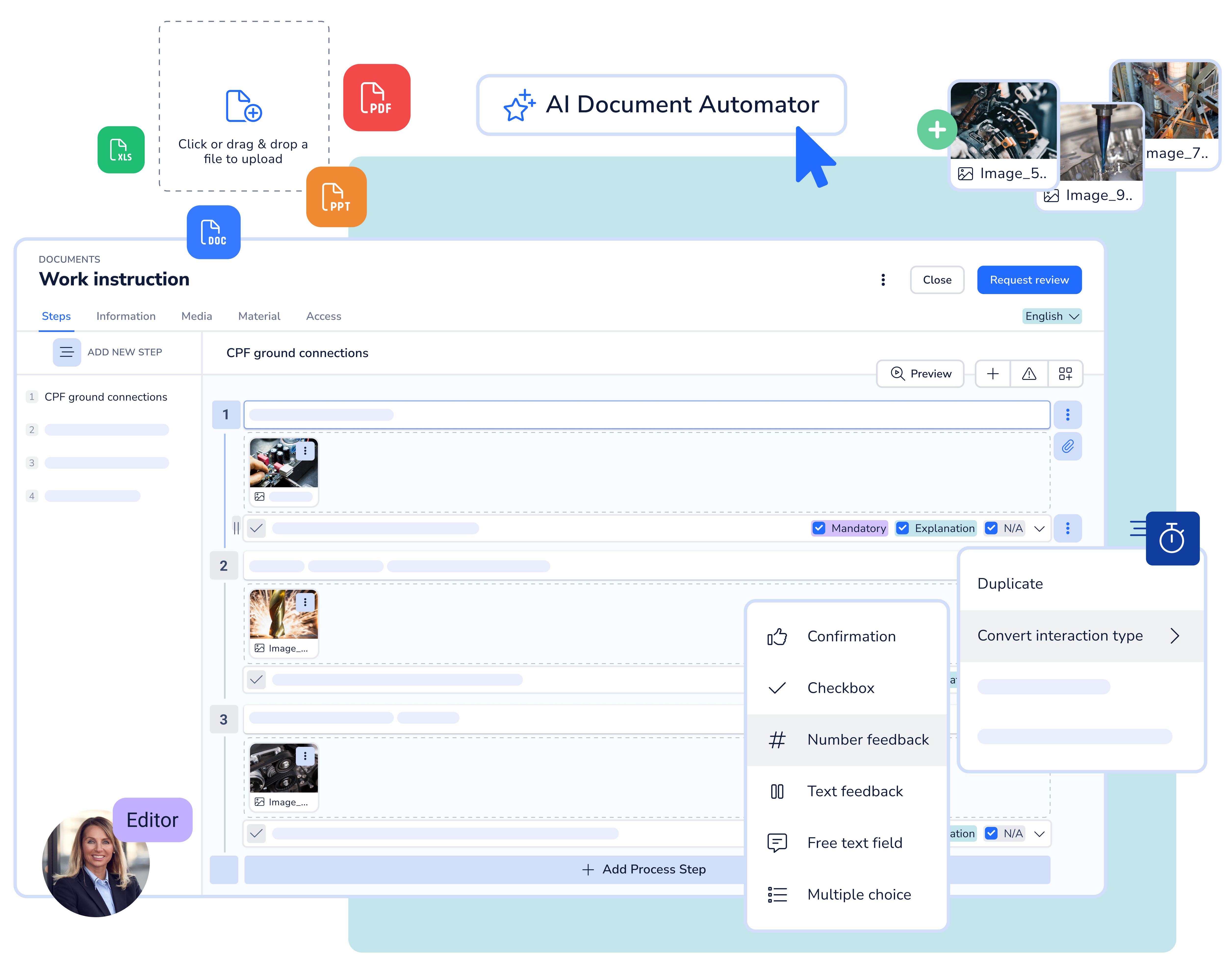

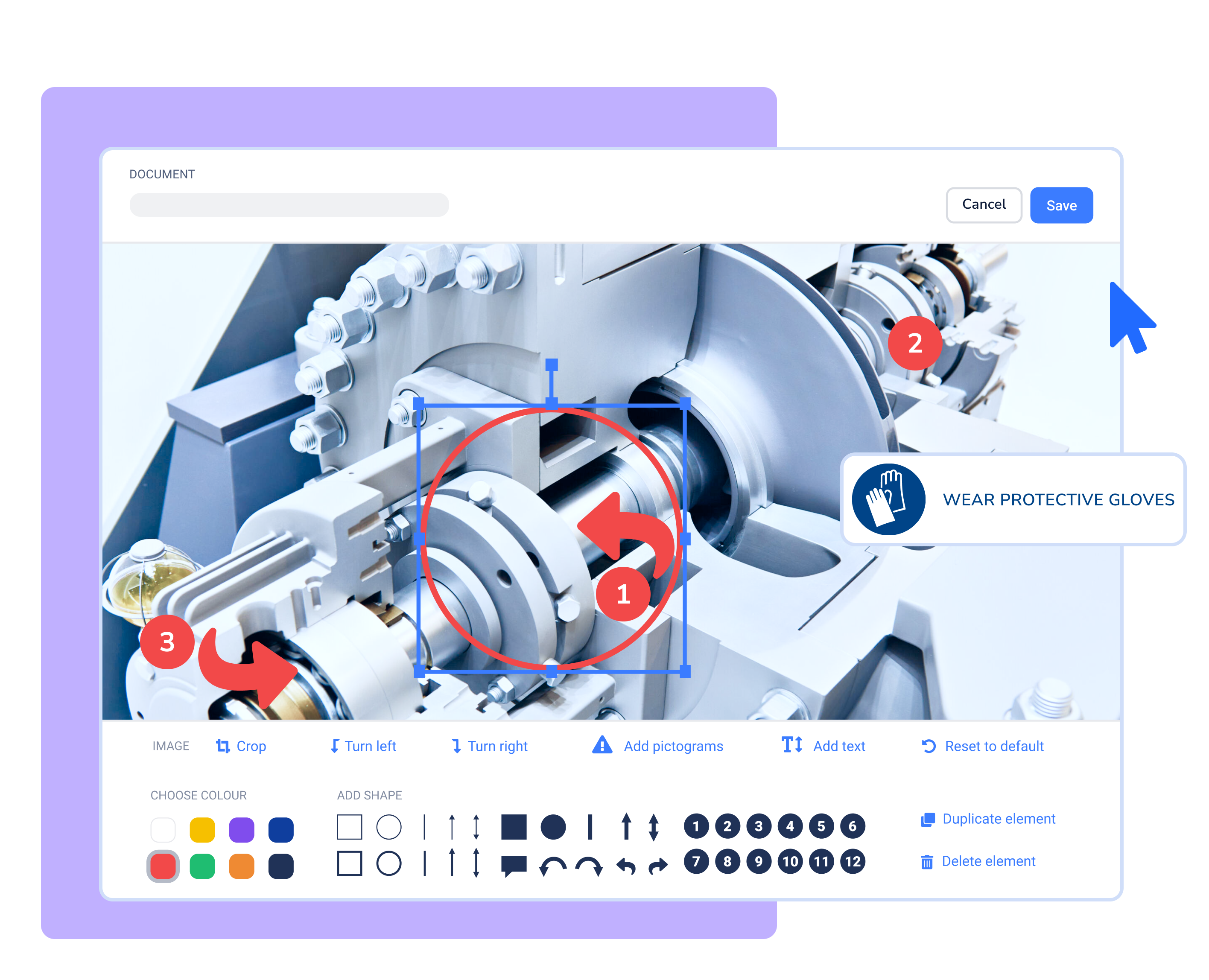

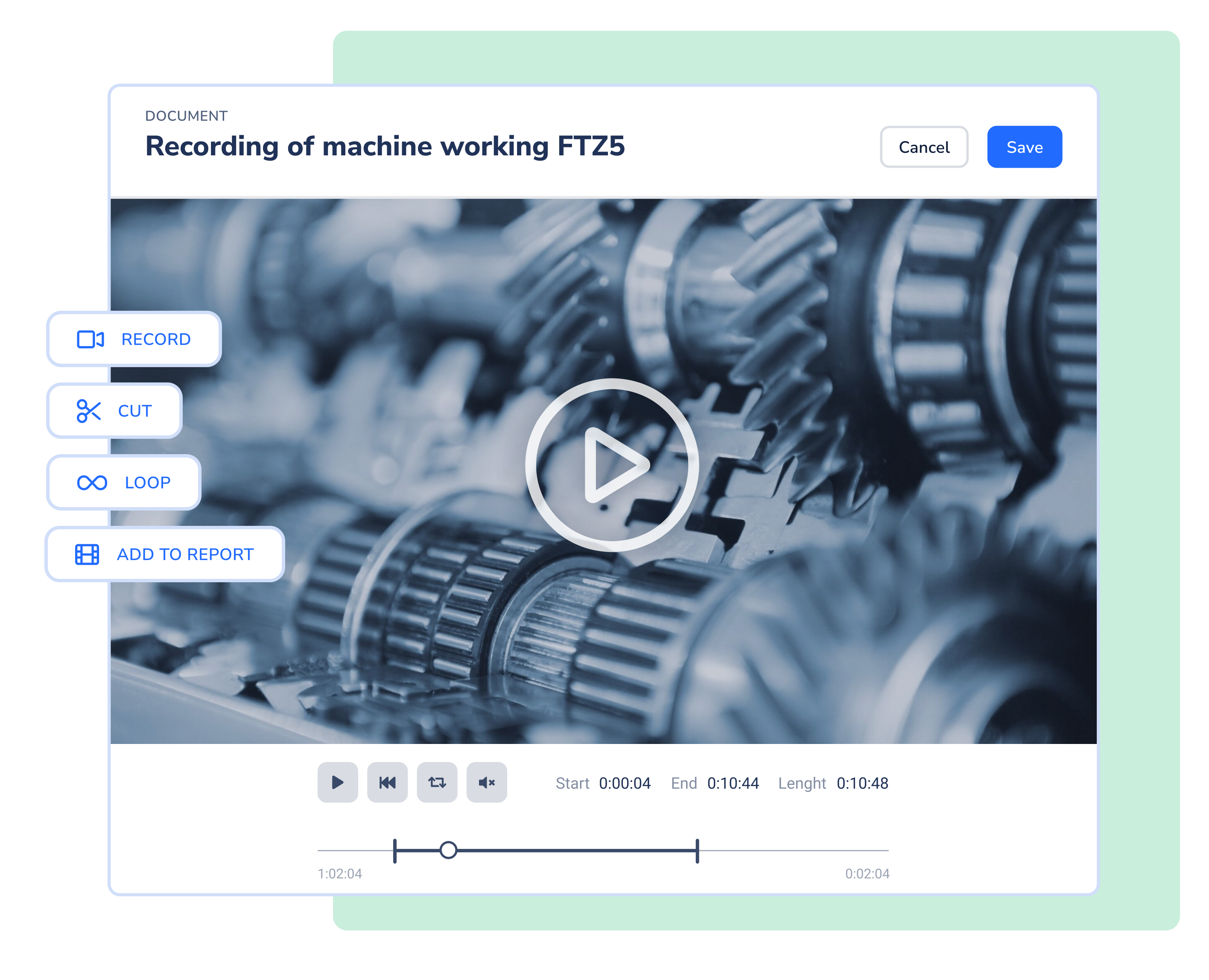

Existing Microsoft Office or PDF documents can be transformed into structured electronic work instructions using the AI Document Automator, without manual transfer errors. The content is enriched with integrated image and video editors that enable visual explanations directly in the work context.