What it's about

In this blog post, we'll explain the different terminology related to worker guidance and list the four success factors for an optimal worker assistance system.

What does worker information system, worker guidance and worker assistance system mean?

Worker guidance is the targeted guidance of a worker through a process. A so-called worker assistance system supports employees in their daily work by providing relevant information. This can happen on a physical or cognitive level.

Physical assistance is primarily concerned with avoiding physical stress disorders of employees (e.g. through heavy lifting). On the cognitive level, an employee is relieved above all on the psychological level by, for example, always having all relevant process information available and thereby being guided through complex processes. This information must be made available in the right form at the right time and in the right place.

This is why worker information systems are often mentioned in this context. In addition to the information function, the cognitive worker guidance also serves to collect production data during the process. But what distinguishes optimal worker assistance system? We show you the four central success factors.

Success factor 1: Versatile provision of information and interactivity

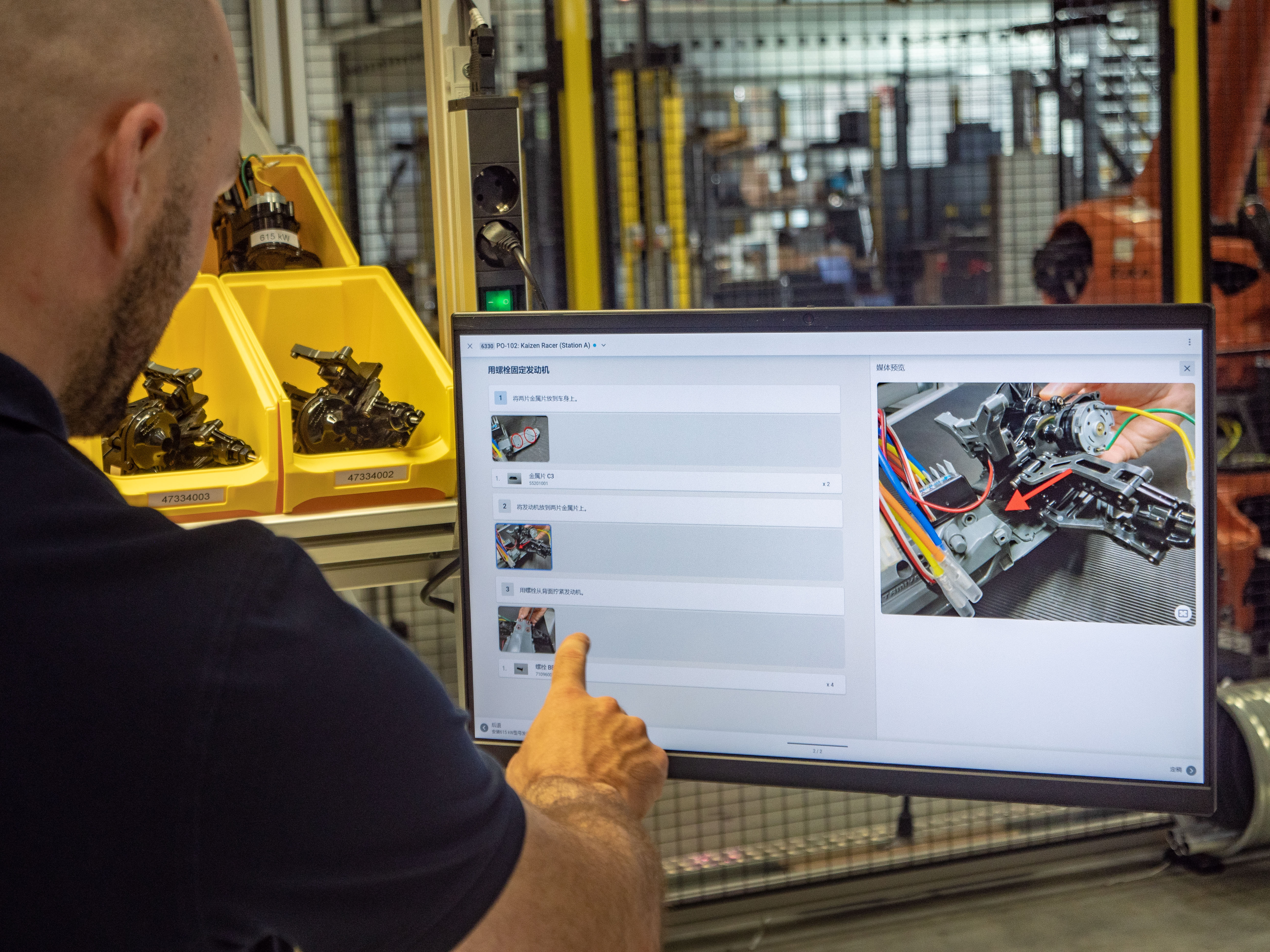

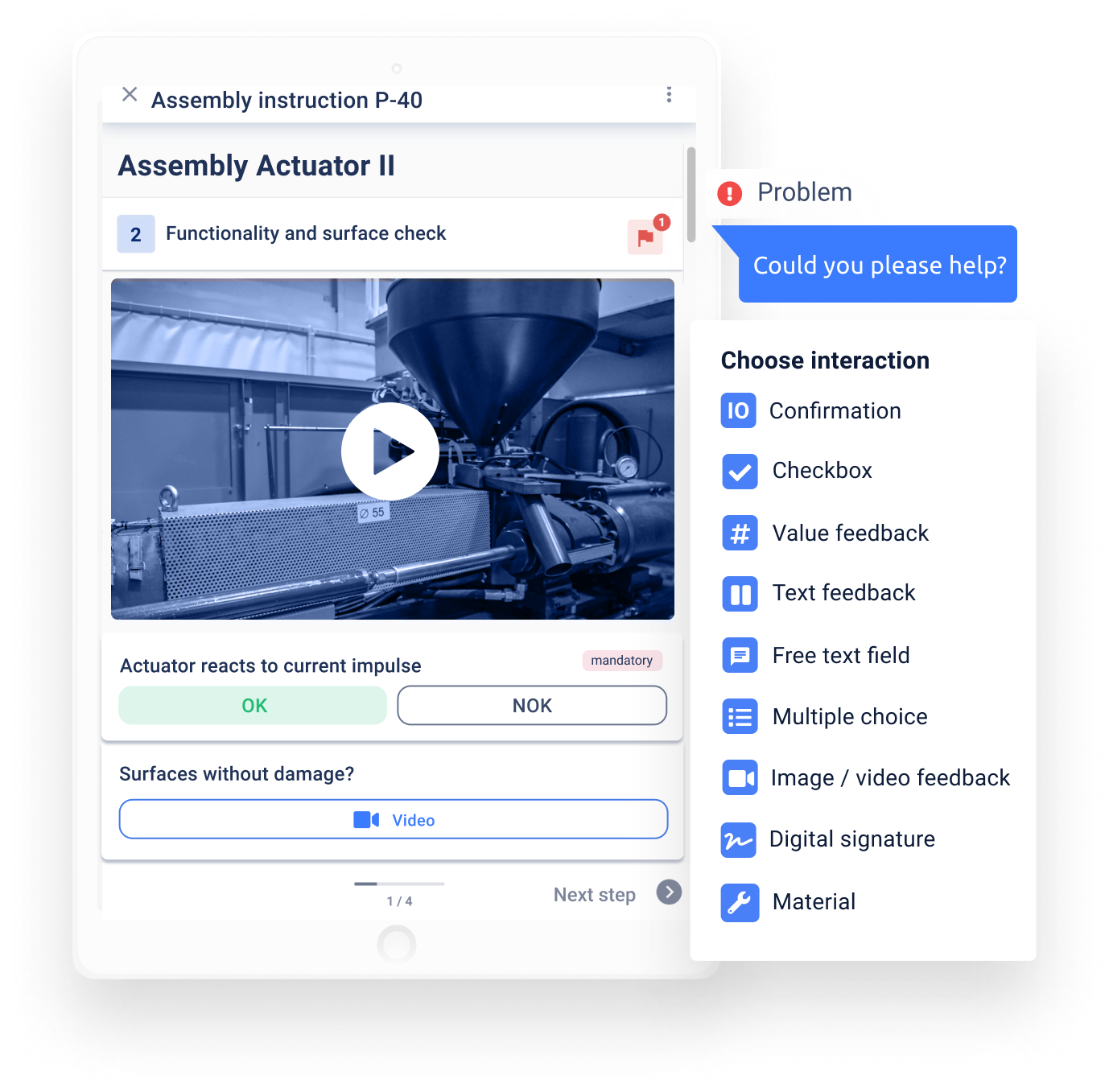

A worker information system provides the employee with information that guides him step-by-step through the required process. The employee also receives information on frequent errors and possible hazards. Safety symbols and warning signals ensure optimum protection for the employee. Images, videos and graphics make the instructions idiomatic and easy to understand. An important element in the provision of information is interactivity, which can be used to retrieve the information as required and thus does not overburden the employee by displaying “all at once”. In addition, a good opportunity for interaction with the medium increases employee acceptance.

Success factor 2: Flexibility

A worker guidance system is ergonomically placed at the workplace so that the employee can always access it without any problems. Information is available both stationary and mobile and is based on the order to be completed, i.e. it is available as needed. Each required manual must be easy to retrieve. At the same time, the employee should ideally be interactively involved in the operation of the software. The ideal worker assistance system also integrates documentations. This often is the employees’ most unloved task, because it is time-consuming and is often postponed to be done “after the actual work”. But a correct and detailed documentation is the basis of a successful and functioning production. Therefore the documentation deserves special attention and should not be neglected. In addition to providing information, software for worker assistance also integrates the documentation directly into the process with just a few clicks.

Success factor 3: Versatile application possibilities

A good cognitive worker guidance is flexible. It is not limited to a specific process, such as assembly, but can be implemented throughout the entire production process. It also maps maintenance, quality inspection and many other processes. This creates a uniform information platform and the employee does not have to master different software for each process. In the best case scenario, “using synergy effects” is not just a buzzword, but reality because application cases can be scaled. Another profitable feature are the feedback options available for each task. Workers actively support the optimization of the process and valuable know-how no longer disappears unheard into the wide open spaces of the production hall.

Success factor 4: Scalability and future orientation

The selected system must be able to grow with the company. This refers to the fact that it must be possible for the company to quickly and easily equip the entire production and all production employees with the system in extreme cases. This results in a variety of requirements, such as a simple user interface to keep training costs low. Compatibility is also essential, whether with existing ERP systems or the processes in the company. The worker assistance system must therefore not only be able to grow with the size of the company but must also be technologically oriented to the latest technologies, so that the company does not have to work with an outdated system after just a few months.

Conclusion

A worker assistance system must be flexible enough to meet the numerous requirements of modern production and at the same time represent these in the simplest and most intuitive way possible in order to offer added value for the company. With cioplenu, you can rely on a safe and trustworthy partner who will guide you through the jungle of digitalization in an uncomplicated manner and make your production more efficient, even with lot sizes of 1.

Work Instruction 4.0

With digital work instructions and checklists, you increase efficiency and make better decisions. Read in our whitepaper how our software solution can help you!

Daniel Grobe

Daniel Grobe (M. Sc., Management & Technology) founds cioplenu GmbH in 2017 together with Benjamin Brockmann (also M. Sc., Management & Technology). The founders develop the software solution on the basis of various practical projects, including at the Fraunhofer Institute, and their experience in industry, auditing and management consulting. Daniel Grobe is a Junior Board Member of bayme vbm and has already worked for companies such as KPMG and Continental.