What it's about

In this blog post, we'll give you five benefits of digital assembly instructions. Learn how they can help you to easily map technical complexity and at the same time increase quality, transparency and employee satisfaction.

What are digital assembly instructions?

Assembly work instructions are a powerful tool for guiding employees. Like paper-based instructions, they belong to the category of work instructions and are designed to explain how best to perform a specific task - in this case, assembling a component or machine. Unlike paper-based solutions, however, they are flexible, scalable and easily accessible to those who work with them.

5 benefits of digital assembly instructions for manufacturing companies:

#1 Managing technical complexity

Traditionally, instructions have been provided in the form of printed documents or PDF files. However, the increasing demand for product customization has inevitably led to production environments becoming significantly more complex. As a result, employees must regularly review and create new assembly instructions to keep up with all the changes. Printed or PDF-based instructions are simply too cumbersome to efficiently manage this complexity. One of the ways that digital assembly instructions solve this complexity is by using variant configuration.

Digital assembly instructions also make extensive use of visual content such as images and videos. Such formats are far more efficient and accessible than lengthy, written instructions. Employees can use videos to better understand how to perform assembly. At best, visual instructions also include examples of how to use the product. Installation situations in the end product are also helpful for complex machine parts and components, for example.

#2 Reducing skills gaps

It usually takes several months for new employees to reach their maximum productivity, and during this time they must undergo extensive on-the-job training. While theoretical instruction is still essential in certain applications, there is no substitute for on-the-job learning in a manufacturing industry. New employees depend on understandable and well-formulated work instructions.

Digital assembly instructions make it easier to train new employees . The digital approach enables hands-on on-the-job training and promotes continuous learning by showing production workers exactly how to perform assembly steps and other tasks in a safe, efficient and standardized manner.

#3 Detecting (quality) issues at an early stage

Reducing human error must be a top priority for manufacturing companies, as it can lead to costly scrap production or worse, serious personal injury. Employees are far more likely to make mistakes if the instructions available to them are not clear enough.

Digital assembly instructions lead to fewer errors because they guide employees through processes reliably and step-by-step. After all, it's much easier to glance at visual information on a tablet screen than it is to dig through pages of printed technical documentation. In addition, because it's also easier to update digital guidance and evaluate it in real time, supervisors can identify and correct any problems early on. Data, such as error images or process cycle times, stored with digital assembly instructions can be used for later analysis and process optimization. Integrated worker self-inspection also becomes possible with digital work instructions: assembly processes are carried out reliably and quality inspection can take place at the same time.

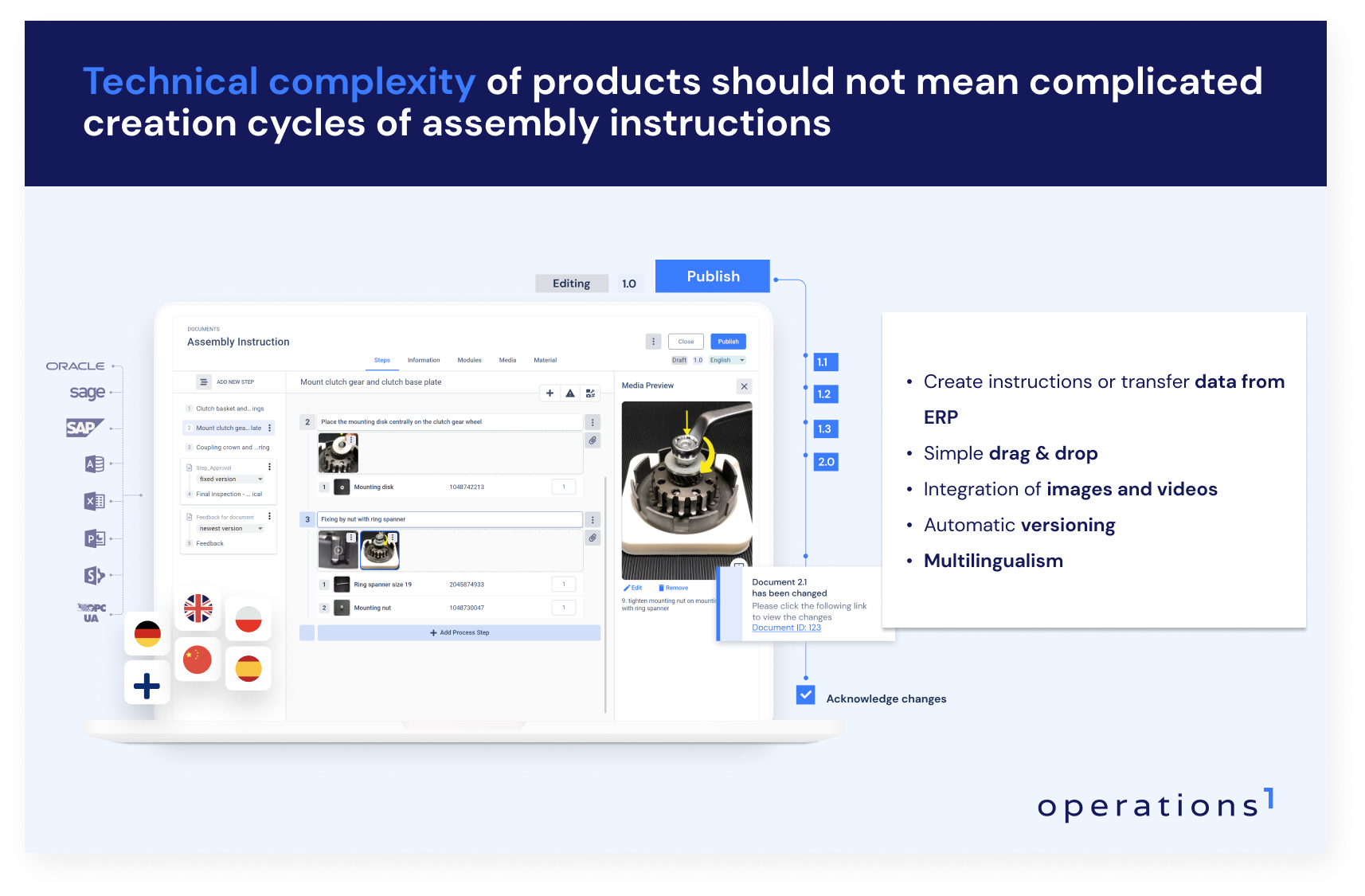

#4 Facilitating creation and updating

Although operating systems such as Microsoft365 make it easier for many manufacturing companies to create instructions and store them in share folders for everyone to access, it is not yet digitization in the true sense. Creating, versioning and archiving work instructions is still complex - especially since production employees rarely have their own workstations with computers from which they can easily access the latest version. Therefore, assembly instructions created with Word, PowerPoint and Excel are still printed out and distributed. If a change is made to the instructions, it must be ensured that the latest version is available on the store floor at all times. With digital assembly instructions on a smartphone or tablet, employees have all the necessary information at their fingertips in real time.

Word processors like Word or Excel also don't have the features needed to format instructions in a user-friendly way - at least not without a lot of extra work. The digital assembly instruction takes a modular approach by allowing videos, images and graphics to be dragged and dropped into the instruction. Product-specific structural data can also be easily provided for each product without any additional effort. The required information flows directly from the company's own ERP. Another advantage is multilingualism: a software solution enables manufacturing companies to maintain consistent production and quality standards across country and language borders.

#5 Democratizing knowledge

For any company, its most valuable asset is its most experienced employees. They have years of experience and know the most efficient methods for completing tasks. The problem is that this knowledge is often not documented and is not readily shared outside of personal exchanges or the training of new employees.

Digital assembly instructions can institutionalize the knowledge and experience of qualified employees and thus make it accessible to everyone. Especially in times of demographic change, when more and more experienced employees are retiring while fewer skilled workers are coming on board, this gives companies a competitive edge. Valuable knowledge is not lost and can be easily found and retrieved at any time. The simple retrieval of data creates tribal knowledge and simultaneous transparency from which everyone in the company can benefit equally.

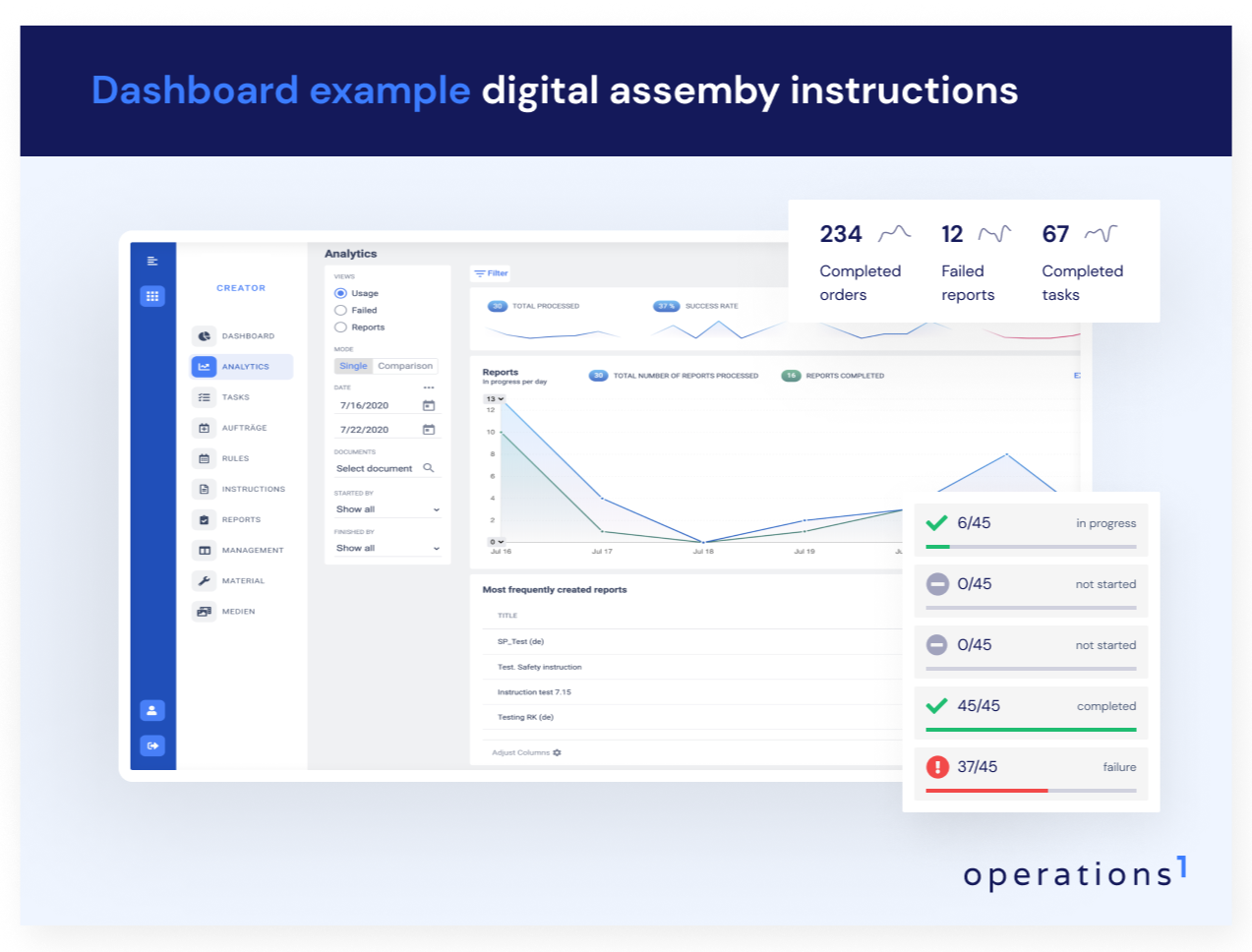

How to choose the right software

A comprehensive solution can provide much more than just assembly instructions. Digital solutions can be dynamically integrated with existing systems, including data analytics dashboards and enterprise resource planning (ERP) platforms. For example, reports could be automatically generated once an assembly operation is completed to give supervisors a clear overview of the efficiency of their instructions and processes. With software based on open interfaces and designed for interoperability, companies can continuously improve the efficiency and reliability of their processes.

When choosing digital manufacturing software, it is important to take a pragmatic approach and first test the proposed solution with employees. As with any digital transformation initiative, open communication with all employees is essential. This helps to increase acceptance. In the case of digital assembly instructions, many of the key benefits are geared toward employees. Above all, ease of access and usability ensure that employees get the information they need to work optimally - and that means higher productivity and job satisfaction.

Conclusion

To remain competitive, manufacturing companies must become leaner and more flexible. The simplest starting point for this is to eliminate activities that do not add value. These activities include the time-consuming, manual creation of assembly instructions and the management of a paperwork economy. Fortunately, many companies have already recognized this and are now using software to create digital assembly instructions. At first glance, the time saved for technically complex products is the biggest advantage. At second glance, however, one discovers many more. Digital assembly instructions help employees in production to carry out assembly activities more reliably, information on the store floor can be stored and made accessible transparently for everyone, and finally the quality of the products themselves also increases.

Would you also like to benefit from the advantages of digital assembly instructions?

Download our epaper "Work Instruction 4.0" and learn how Operations1 can support you in digitizing your assembly instructions.

Get to know the software in just 3 minutes

Discover the functions of Operations1 in an interactive product tour and get to know our platform.

Markus Glotzbach

During his professional career, Markus gained deep insights at companies and large groups in different industries and knows the digitalization hurdles and problems on the shopfloor. Before joining Operations1, he studied International Management (MA) and worked in the Cloud Computing as well as SaaS telematics sector.