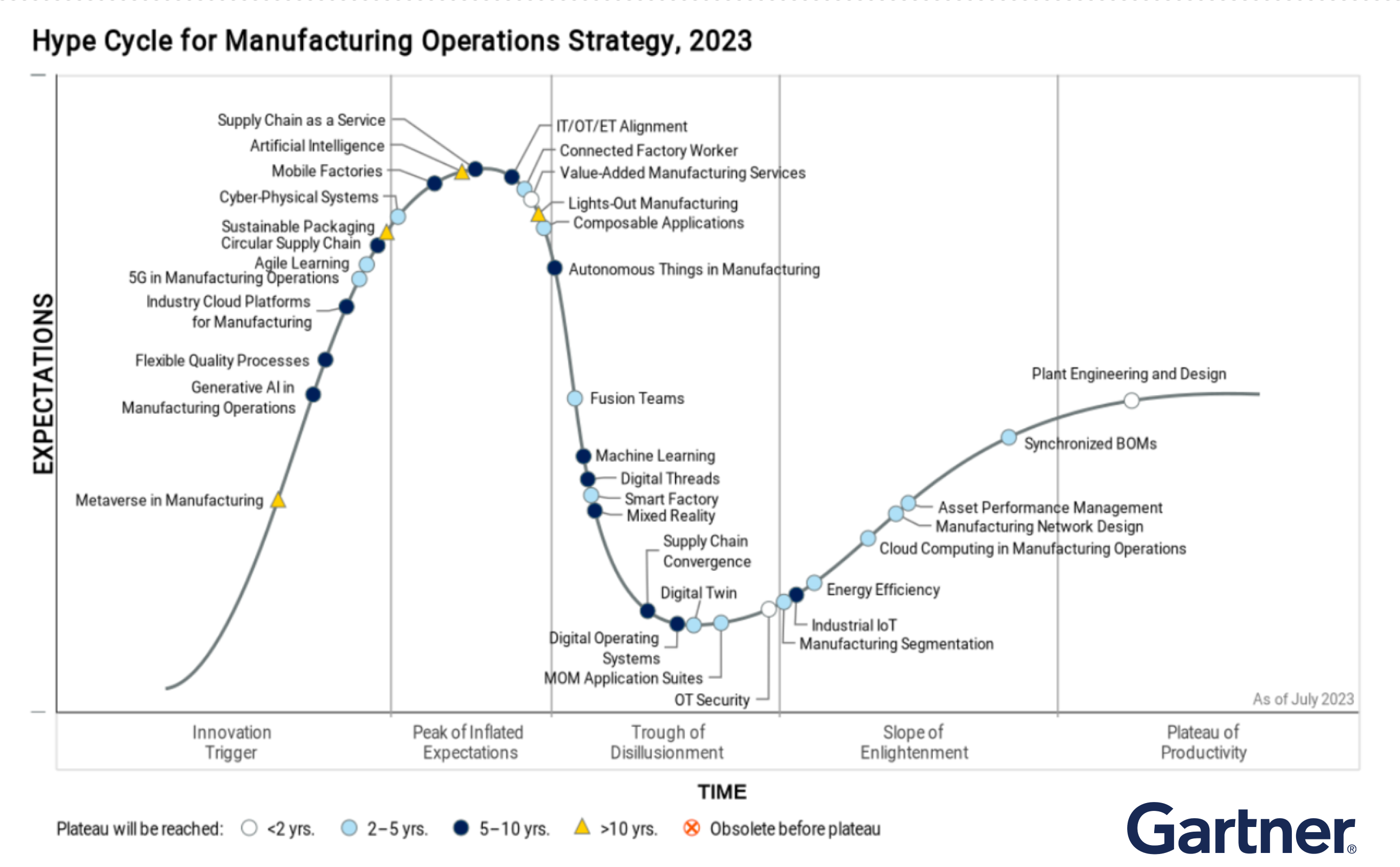

Operations1: A Prominent Player in the Gartner Hype Cycle for Manufacturing Operations Strategy, 2023

Amidst the rapidly evolving manufacturing landscape, Operations1 has secured a significant position in the prestigious Gartner Hype Cycle for Manufacturing Operations Strategy, 2023. As this trend gains momentum, with 5% to 20% market penetration, signaling a promising adolescence stage.

What it is about

In this article, we will delve into the value of digitization in factories, the dual approach to investing in factory workforces, the business impact and driving factors behind this shift, as well as the challenges and recommendations in navigating this transformative journey as highlighted by insights from the Gartner Hype Cycle.

Empowering the Future of Manufacturing: Unleashing the Potential of Connected Factory Workers

1. The Value of Digitization in Factories

In an era of rapid digitization, connected factory workers have emerged as invaluable assets in the manufacturing industry. Seamlessly integrating digital tools into their work processes, these workers enhance decision accuracy, facilitate knowledge sharing, and reduce variability. The result is improved engagement, job satisfaction, and better retention rates among the workforce. As per the Gartner Hype Cycle for Manufacturing Operations Strategy, this digital transformation is essential to keep pace with the evolving industry landscape.

2. Investing in Factory Workforces: A Dual Approach

Manufacturers are increasingly recognizing the critical role played by factory workers in driving success. Embracing a dual approach to investing in the workforce, they are reaping the benefits of this transformative trend. Firstly, manufacturers are embracing technology constructs that revolutionize how factory workers access information and knowledge, catalyzing a transformative change in work processes. Secondly, active implementation of change management initiatives, with a focus on workforce development, behavioral shifts, and integrated continuous improvement, is key to optimizing the potential of connected factory workers.

3. Business Impact and Driving Factors

The impact of connected factory workers on the manufacturing landscape is multi-faceted, as emphasized in the Gartner Hype Cycle for Manufacturing Operations Strategy. Several driving factors contribute to the success and rapid adoption of this transformative trend:

Strengthening Operational Excellence: Connected factory workers enable continuous learning and context-specific operations, leading to heightened operational flexibility, improved output quality, and enhanced efficiency. The insights from the Gartner Hype Cycle underscore the importance of embracing this approach to drive manufacturing excellence.

Fostering Safe and Challenging Work Environments: Prioritizing both safety and challenges in the workplace is essential to boost worker motivation, job satisfaction, and retain valuable talent. The insights from the Gartner Hype Cycle highlight the significance of cultivating such work environments.

Bridging Generational Gaps: As new generations of tech-savvy workers join the workforce, seamless integration between their digital fluency and the knowledge of tenured workers becomes imperative. Striking a balance is essential for effective technology adoption, as underscored by the Gartner Hype Cycle.

Redefining Work Dynamics: Ongoing redesign and digitization of work processes significantly impact productivity, communication, and job roles. The Gartner Hype Cycle emphasizes the importance of embracing digital tools to ensure a smoother transition and enhanced overall productivity.

Leveraging Vendor Solutions: Collaborating with various vendors empowers frontline workers with real-time, context-specific information, driving efficient performance.

Challenges and Recommendations

Despite its transformative potential, embracing connected factory workers is not without challenges. The Gartner Hype Cycle highlights key obstacles and provides valuable recommendations to navigate this transformative journey:

Recognizing Intangible ROI: Acknowledging the value of operational excellence, even when its impact may not be immediately quantifiable, is vital for manufacturers, as emphasized.

Curating Relevant Datasets: Meticulously curating relevant datasets from various sources is necessary to avoid information overload while ensuring operational efficiency.

Engaging Workers in the Solution: Actively involving workers in the design and implementation process fosters successful technology adoption and builds trust, as recommended by the Gartner Hype Cycle.

Evolving Learning and Development: Upgrading learning and development programs to match technological advancements is vital for nurturing a skilled and agile workforce.

Fostering a Data-Driven Culture: Cultivating a culture of data-driven decision-making encourages creativity and innovation among factory workers.

Summary

The Gartner Hype Cycle for Manufacturing Operations Strategy, 2023, illuminates the transformative journey of connected factory workers. Embracing digital tools and data management techniques, these workers are redefining the manufacturing industry. As we navigate this transformative trend, investing in workforce development and embracing change management practices become paramount. The future of manufacturing is bright, and by fostering a data-driven and innovative culture, manufacturers can thrive amidst dynamic challenges, ushering in a new era of empowered and connected factory workers. The insights from the Gartner Hype Cycle serve as a guiding light, leading the way towards a more efficient and digitally empowered manufacturing landscape.

Would you like to learn more about the potential of the Operations1 Connected Worker Platform in your company?

Simply fill out the contact form. We will contact you immediately with the next steps and a proposed date.

Markus Glotzbach

During his professional career, Markus gained deep insights at companies and large groups in different industries and knows the digitalization hurdles and problems on the shopfloor. Before joining Operations1, he studied International Management (MA) and worked in the Cloud Computing as well as SaaS telematics sector.