A pilot project can be launched in just a few weeks. Through gradual implementation – plant by plant or line by line – the benefits become apparent early on and can be scaled up quickly.

Transform your process knowledge. Standardized, variant-specific, and interactive rather than paper-based and scattered.

Achieve up to 300% more output with the same number of employees and existing resources.

Reduce scrap and error rates, and the associated complaints, leading to greater customer satisfaction and loyalty.

The platform's ease of use boosts employee satisfaction and productivity, resulting in lower turnover.

Significantly reduce administrative workload with digital, standardized processes instead of paper and isolated solutions.

Bring expert knowledge and documentation to where it matters most: directly to the workers. With variant-specific, multimedia, and multilingual digital work instructions, checklists, and much more.

Unified data model and mapping of your internal structures for rollouts across sites and countries.

Runs on Microsoft Azure, ISO 27001-certified, with an SAP partnership to meet high security and compliance standards.

Granular permissions, role- and access control, and single sign-on (SSO) for fast, secure login.

Standard connectors and REST API for low-effort integration, including SAP connectivity and use on any device.

Get in touch with our product experts to find out how you can benefit from Operations1.

A pilot project can be launched in just a few weeks. Through gradual implementation – plant by plant or line by line – the benefits become apparent early on and can be scaled up quickly.

Data security is a top priority. Operations1 uses the Microsoft Azure Cloud for hosting — one of the world’s most secure and modern cloud infrastructures. For customers in Europe, data is stored in German data centers (Frankfurt region), ensuring strict compliance with GDPR and local regulatory requirements.

In addition, Operations1 is ISO 27001 certified. The combination of the highly secure Azure infrastructure and certified internal processes ensures high availability, redundancy, and protection against unauthorized access—an essential factor for IT compliance in industrial environments.

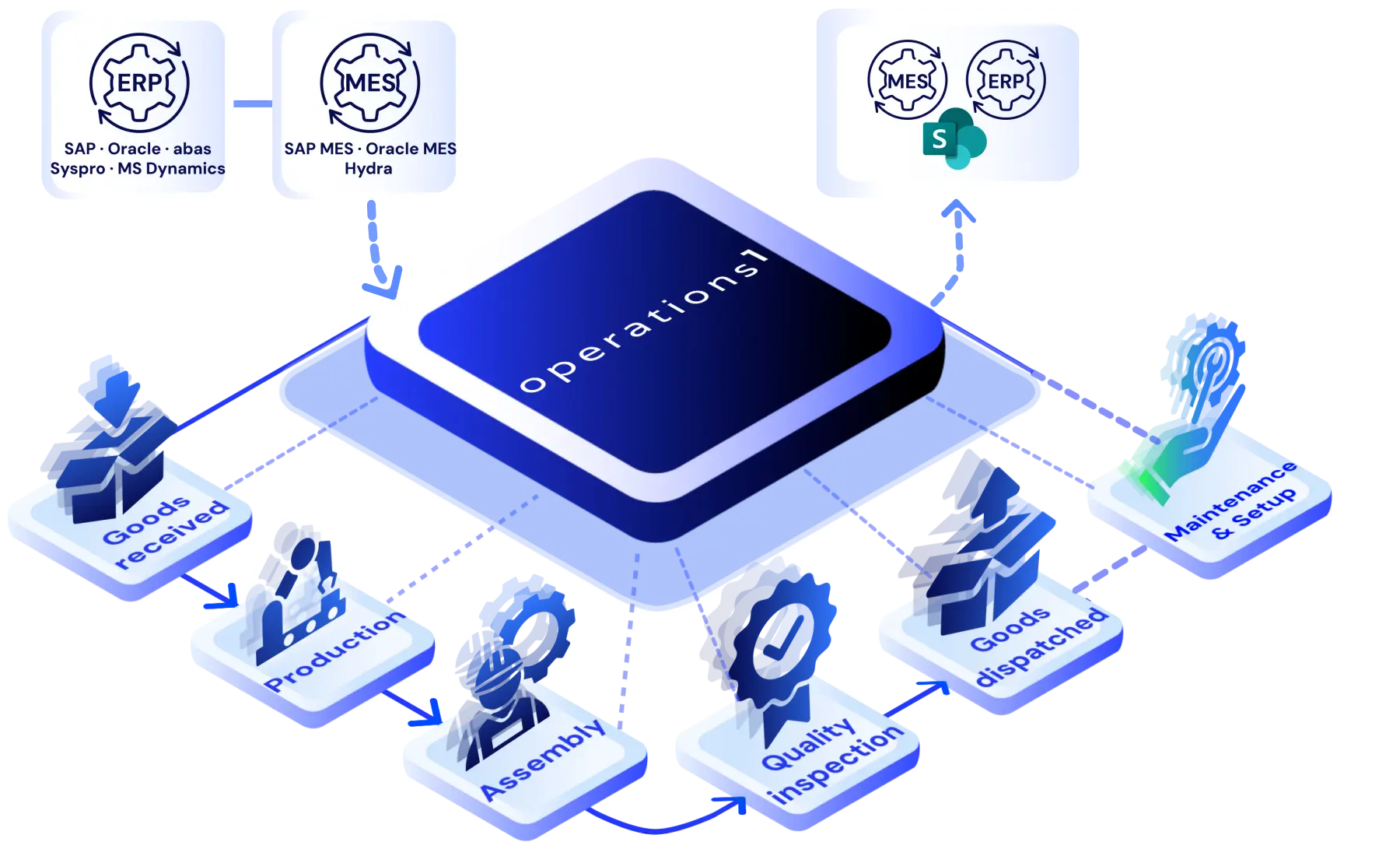

Yes, Operations1 offers various integration options with existing ERP, ME and CMM systems. Our REST API enables integrations to all modern cloud and on-premises systems to connect the Operations1 platform.

Yes. The Operations1 Connected Worker App is designed and optimized for industrial use on tablets and smartphones. It provides mobile access to all processes directly at the point of action—including an offline mode for areas without stable network coverage.

Using Operations1 delivers clear benefits for manufacturing optimization:

Efficiency gains: Reduced downtime and shorter cycle times.

Knowledge transfer: Effective onboarding despite skilled labor shortages by digitizing tribal knowledge.

Quality assurance: Significant error reduction through guided processes (Poka Yoke) and complete, audit-proof documentation.

OEE optimization: By digitizing shopfloor processes, you directly improve overall equipment effectiveness (OEE). The platform reduces unplanned downtime (availability), minimizes minor stops through clear work instructions (performance), and lowers scrap rates through guided quality checks (quality).

Cost efficiency: Fast ROI by eliminating paper-based processes and reducing manual data re-entry.

Operations1 brings together all key tools for the modern shopfloor:

Digital work instructions & SOPs: Intuitive step-by-step guidance with multimedia support.

Checklists & audits: Digital execution of 5S audits, 6S audits, and inspection records.

Maintenance planning: Intelligent management of maintenance intervals.

Incident management: Immediate reporting of deviations directly via the Connected Worker App.

Analytics: Dashboards for analyzing process data to support continuous improvement.

Connected Worker software acts as the company’s digital memory. It ensures that less experienced employees can carry out complex tasks reliably through guided workflows.

This speeds up onboarding and relieves experienced specialists by reducing follow-up questions and rework.

A Connected Worker platform is a central digital infrastructure that connects frontline workers in manufacturing with information, machines, and IT systems. Unlike isolated tools, it integrates digital work instructions, communication, and documentation in one system. The goal is paperless manufacturing, where data flows in real time between the shopfloor and ERP-systems such as SAP to improve operational excellence.

Above all, manufacturing companies for example, in mechanical engineering, plant engineering, vehicle construction, or the food industry. Digital work instructions have the greatest impact wherever there are many variants, language versions, and audit requirements.

A traditional worker assistance system is often an isolated solution that only provides digital instructions at the workstation. A platform like Operations1 goes far beyond that. It functions as an integrated ecosystem. While a system only delivers information, the platform enables bidirectional data exchange with ERP systems, supports maintenance process management, scales globally, and provides deep insights into process performance.