Build future-proof operations

External shocks such as supply chain disruptions, climate events and political crises pose new challenges for manufacturing companies. At the same time, a shortage of skilled workers and international competitive pressure are forcing companies to react more agilely to changes. With Operations1, the step from paper-based, intransparent operational processes to agile, lean and, above all, future-proof production can be taken.

- +21% higher productivity

- +55% higher quality

- +65% faster ramp-up

Lighten up the blind spot

Tap into unprecedented data pools through a fully connected organization and facilitate better decisions

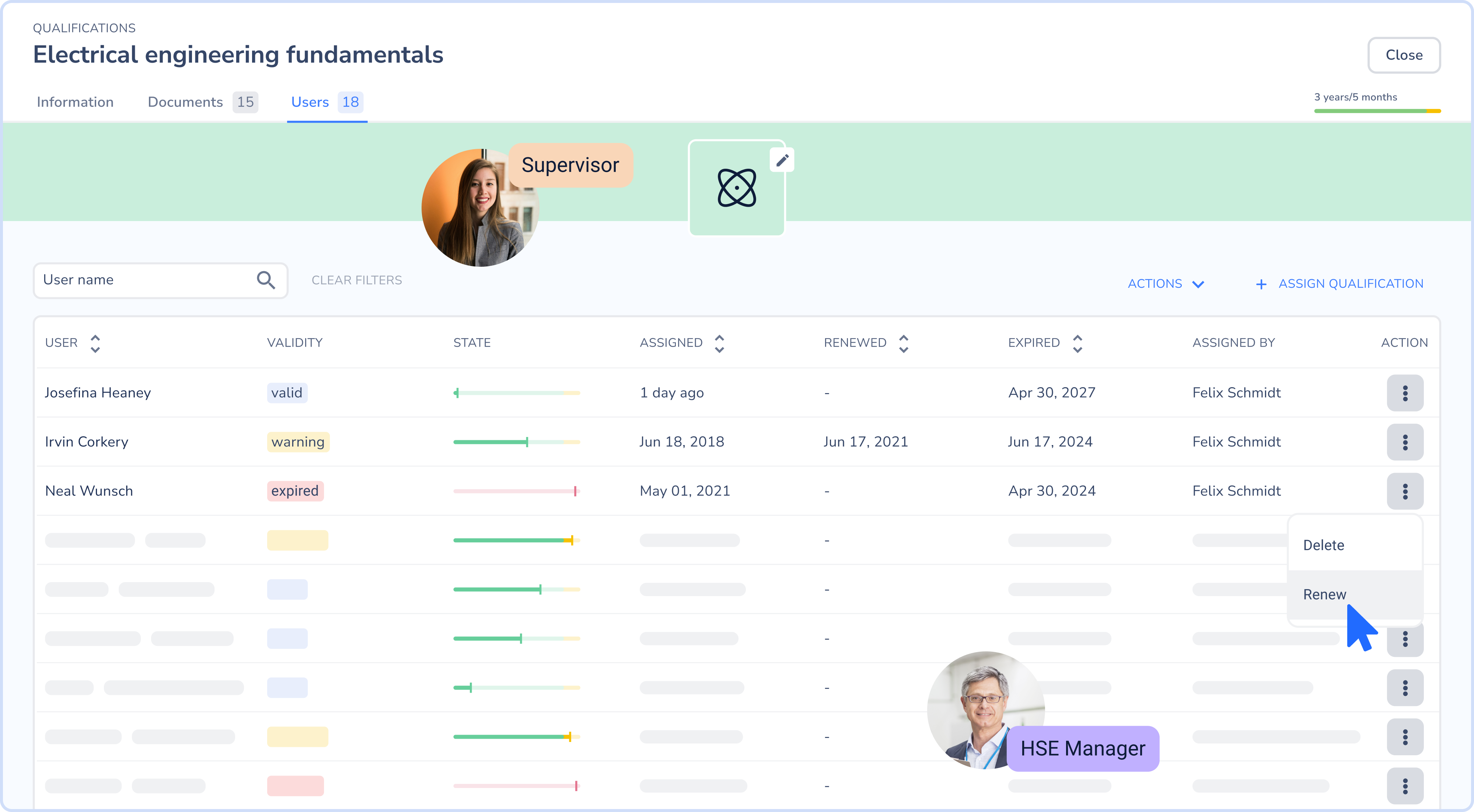

Comprehensive live transparency of process data and statistics

Live monitoring of your employee-led production processes

Collaborative problem solving with transparent tracking

Improve velocity by 65%

Globally manage and distribute in-depth knowledge to reduce onboarding times and perform processes reliably

Sustainable knowledge retention with easy updating and deployment

Scalable organization of knowledge across teams, sites, and product lines

Reduced training effort for new employees through intuitive process guidance

Strengthen resilience

Quickly adapt and deploy processes worldwide and respond to changing production requirements and external shocks

Acceleration of process adaptations through simple updating and release

Variant-specific production processes enable increasing customer demands for individualization

Insourcing of activities through simple knowledge transfer

Learn more about the Operations1 platform

Our experts will be happy to advise you on how we can support you on your way to future-proof operations.