Webinar recap: Digital qualifications and knowledge management

Increased process reliability and flexibility for your shopfloor employees - Production managers do not have an easy job in their day-to-day work: they must always ensure a high level of occupational safety, keep track of employee qualifications, ensure that new employees are trained quickly, and respond flexibly to personnel shortages in processes. But where Excel lists, paper-based processes, and unsecured knowledge pose problems for personnel managers, digital tools for qualification and knowledge management can provide enormous support.

What this article is about

In this recap of the webinar “Digital Qualification and Knowledge Management,” you will learn:

- What problems arise when managing employee qualifications and process knowledge

- How to solve these problems through holistic knowledge and qualification management with digital tools

- What added value this can bring to daily business on the shopfloor

Challenges of manufacturing companies

Production executives such as plant managers, production managers, and department heads are responsible for ensuring that processes run as smoothly as possible and productivity remains high on a daily basis. And although people are the most valuable resource on the shopfloor, this factor presents daily challenges:

Demographic change and skills shortages: There is a lack of simple solutions or support tools that can sustainably cushion the negative effects of staff shortages on the shopfloor.

Loss of expert knowledge: When employees leave (retirement, job change, long-term illness), there is a risk that the tacit knowledge of experienced employees will be lost.

Ensuring quality standards: Qualified personnel and standardized processes are often not equally available in all shifts, departments, or plants to ensure a uniform quality standard.

Maintaining productivity: Paper-based processes in particular involve a lot of manual effort and efficiency killers that prevent companies from producing in a more value-adding way.

Complying with EHS regulations: The shop floor often lacks the necessary tools to ensure process reliability, complete documentation, transparency, and compliance-compliant processes.

Challenges in knowledge management

Challenges in knowledge management

Taking a closer look at the topic of knowledge management, the problems faced by manufacturing companies can be described as follows:

Unsecured expert knowledge: Process knowledge is often stored in the minds of employees – and is therefore lost entirely when they leave the company – or is fragmented across handwritten notes and MS Office documents. In addition, there is often no single point of truth that all key stakeholders can access or that enables the introduction of process standards.

Complex information and lengthy training processes: Paper on the shopfloor is often identified as the main source of inefficiency in processes – but complex information presentation is often the real efficiency killer for employee-led activities. Employees receive a variety of documents that are very text-heavy and complicated. New employees in particular find it difficult to work their way through the mountain of paper containing complex information during onboarding and the training process. However, the following applies to all employees: complex information means a high level of interpretation effort and costly time losses, as well as potential for errors in operational processes.

Master-apprentice principle: The master-student principle is a common standard in training. The downside of having an experienced employee train new employees is that the master is tied up as a resource: they have to look over the new employee's shoulder and be available to answer questions. This means that he cannot perform value-adding work himself during the training period. Manufacturing companies are looking for more efficient training methods, particularly in this area.

Language barriers on the shopfloor: In practice, it is not a given that foreign-language employees – whether permanent employees or temporary workers – will be provided with information in their native language. The middle ground here is often the English language: However, if employees only have a basic knowledge of English, these language barriers can lead to slow work, mistakes, and frustration when communicating with colleagues and working with paper-based instructions.

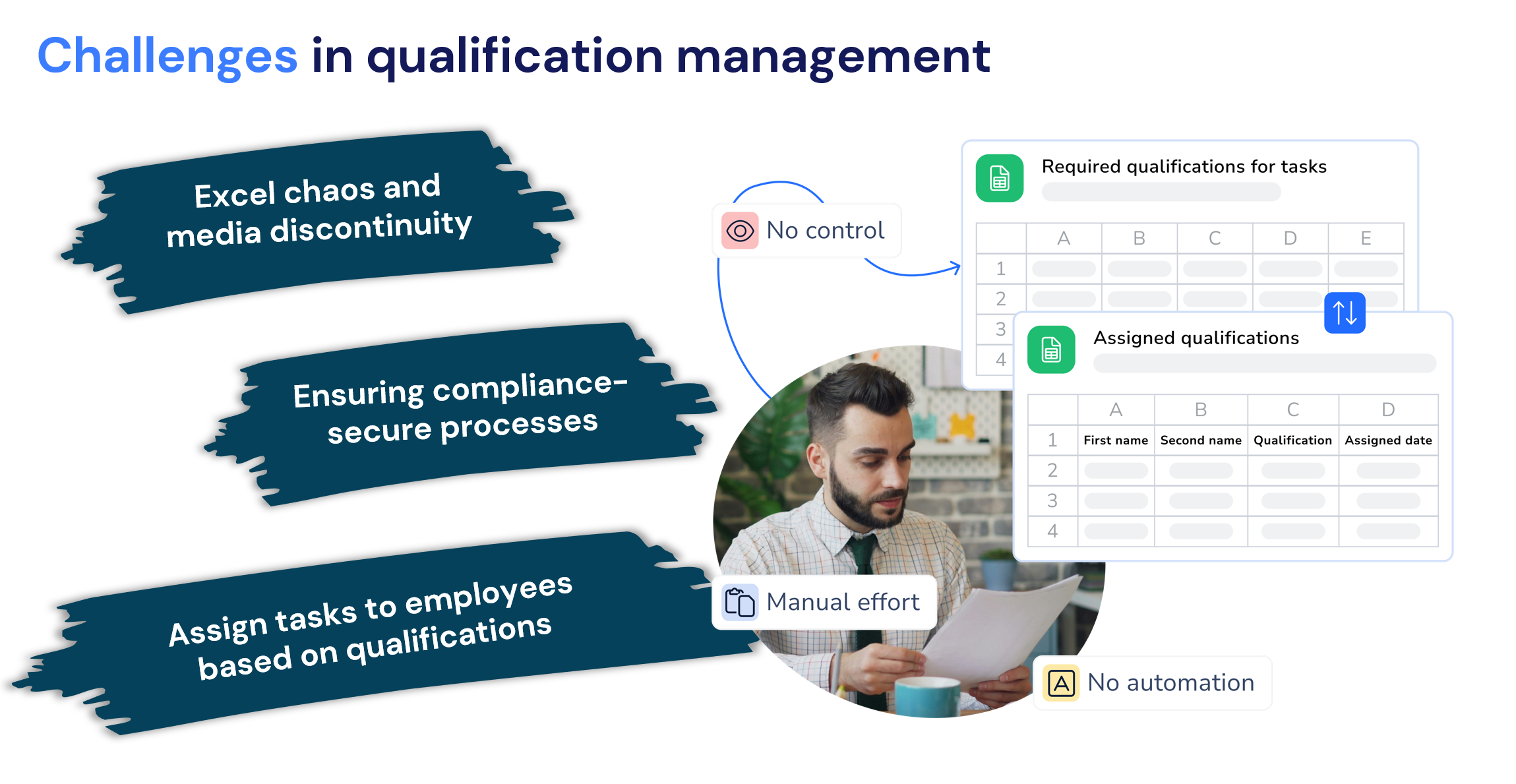

Challenges in qualifications management

Production managers must regularly consider these two key aspects: What qualifications are required for the tasks on the shopfloor? Which employees have these qualifications to meet the qualification requirements? The operational level for accomplishing this task often presents the following challenges:

Excel chaos, media discontinuity, and lack of transparency: In practice, employee qualifications are often maintained in Excel lists—in the best case, centrally by one department, but often department-specific. If there are multiple Excel lists or if qualifications are still maintained in other systems or even on paper lists, versioning and transparency problems often arise: There is a lack of clear responsibilities, control mechanisms, and a clear overview of employee qualifications.

Upskilling and cross-skilling employees: People managers should always make sure that the skills needed on the shopfloor are covered by well-trained employees—especially when there's a shortage of skilled workers or employee turnover. However, if there is no clear overview for quickly identifying qualification gaps or further training potential among employees, the result can be a mismatch between qualification requirements and availability. It is therefore advisable to promote upskilling (deepening existing skills) or cross-skilling (learning new skills) among shop floor employees in order to be prepared for all eventualities.

Ensure compliance-secure processes / assign tasks to employees based on qualifications: If employees are absent due to illness or retirement, these personnel gaps must be quickly filled in operational processes. In order to maintain occupational safety and comply with legal regulations, HR managers must ensure that, for example, only those employees who have the necessary qualifications are assigned to dangerous tasks.

Solution: Digital knowledge management

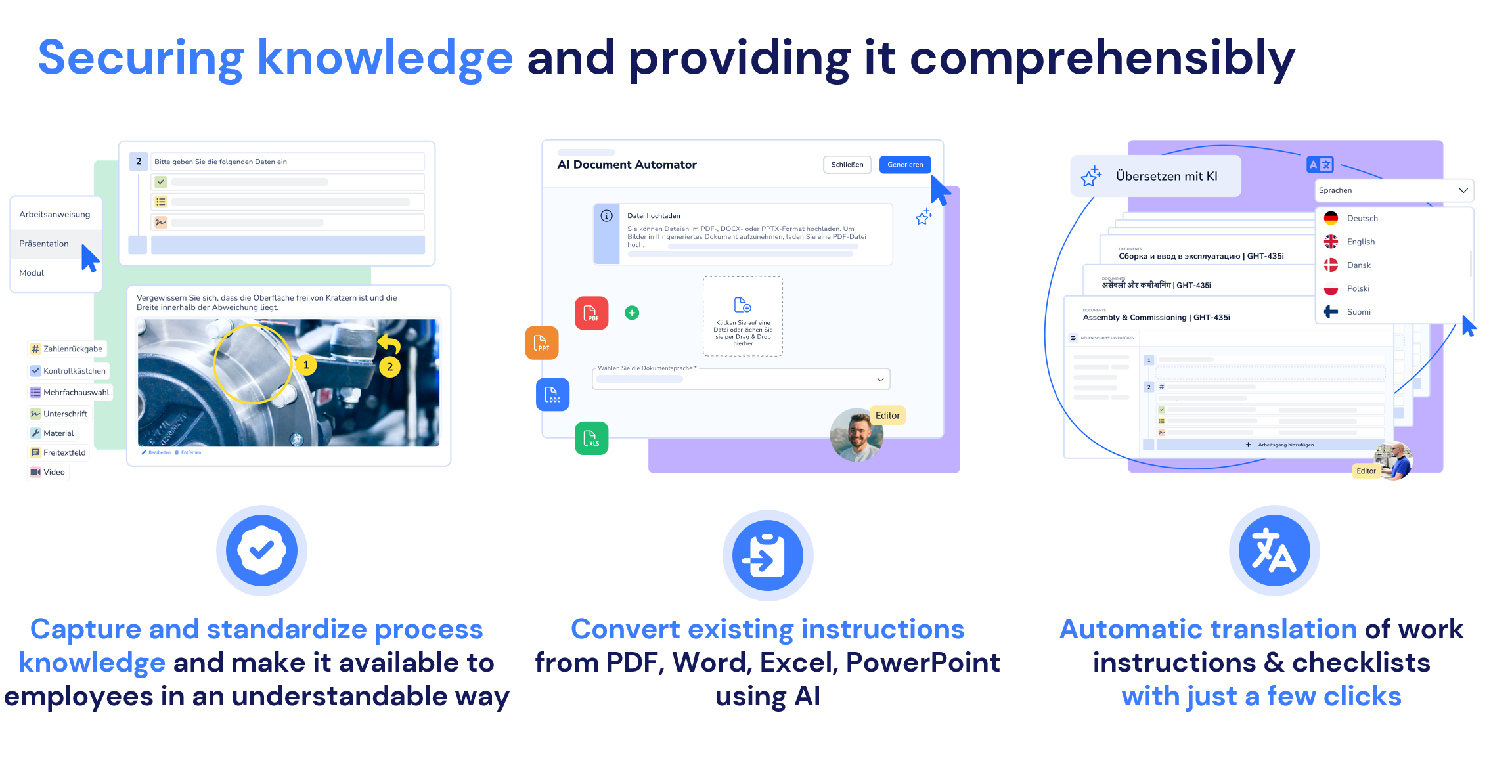

In order to avoid inefficient training processes and the risk of losing important expert knowledge, which is of enormous importance for their own competitiveness, more and more production managers see digitization as the solution. However, it quickly becomes apparent that holistic software solutions such as MS Office are limited in their functions and added value, so the choice falls on specialized software and digital tools.

Specialized software such as a connected worker platform offers integrated functions such as a no-code document editor, which enables the creation of easy-to-understand step-by-step instructions for employees using interactive elements, videos, and images. AI-supported functions also facilitate the creation of digital instructions or training documents.

Process knowledge is thus secured by digital checklists and work instructions and can be made available to employees worldwide in multiple languages. Efficiency gains can be achieved, particularly when training new employees or increasing the flexibility of experienced employees, as clear instructions enable independent and safe training.

But that's not all: digital work instructions and checklists enable managers such as plant managers, production managers, etc. to establish process standards that can be made available to multiple plants globally in order to achieve a uniform global quality standard.

Solution: Digital qualifications management

It is extremely important for personnel managers to have a point of truth regarding the qualifications required and available on the shopfloor. A digital qualification matrix or skill matrix not only shows the qualifications per employee, but also makes it possible to identify the qualification status and recognize qualification gaps or training needs per employee: If a supervisor knows that an employee will no longer be available in the foreseeable future due to retirement, they can proactively plan which qualifications need to be covered by other employees. Training documents can also be created and employees assigned to acquire these new qualifications at the touch of a button.

In addition to a qualification matrix, digital qualification management offers increased transparency regarding whether and to what extent employees have completed individual training steps in a digital training document through the digital logging of completed training courses. This digital reporting can be used not only as proof, but also to improve training processes and training materials.

When selecting qualification management software, production managers should ensure that the software includes features that reduce effort, such as useful functions like simple multiple assignment of qualifications, filters, or the display of qualification validity periods.

An increased level of process reliability can be achieved primarily through software-supported verification mechanisms, where the software automatically stops employees if not all the necessary qualifications for a task or order are stored in the user account.

The advantages of digitizing knowledge and qualifications management:

Centralized securing, standardization, and provision of knowledge

to prevent knowledge loss and ensure uniform quality standards

Clear and efficient management of qualifications

for easy identification of qualification gaps and training potential

Faster training of new employees

so that employees can become productive and add value more quickly

Flexibilization of experienced employees

to close personnel gaps in operational shopfloor processes (cross-skilling)

Increased process reliability and improved occupational safety

to reduce costly errors and comply with legal requirements

Conclusion

Digital qualification and knowledge management enables companies to map the skills and expertise of their employees in a transparent and up-to-date manner. This allows qualification gaps to be identified at an early stage and targeted training measures to be initiated. At the same time, legal requirements and quality and safety standards are reliably complied with. Companies benefit from greater efficiency, increased flexibility, and resilient competence development. This creates the basis for successfully meeting the challenges of modern production and working environments in the long term.

Now is the right time for digital qualification and knowledge management!

Contact us and we will discuss your first steps toward digitalization with you.

Markus Glotzbach

During his professional career, Markus gained deep insights at companies and large groups in different industries and knows the digitalization hurdles and problems on the shopfloor. Before joining Operations1, he studied International Management (MA) and worked in the Cloud Computing as well as SaaS telematics sector.