Leading companies rely on Operations1

Digital work instructions and checklists help you optimize your production efficiency, reduce costs, and create opportunity for growth.

Centrally define the process standards for your production and make this knowledge available to all your locations worldwide.

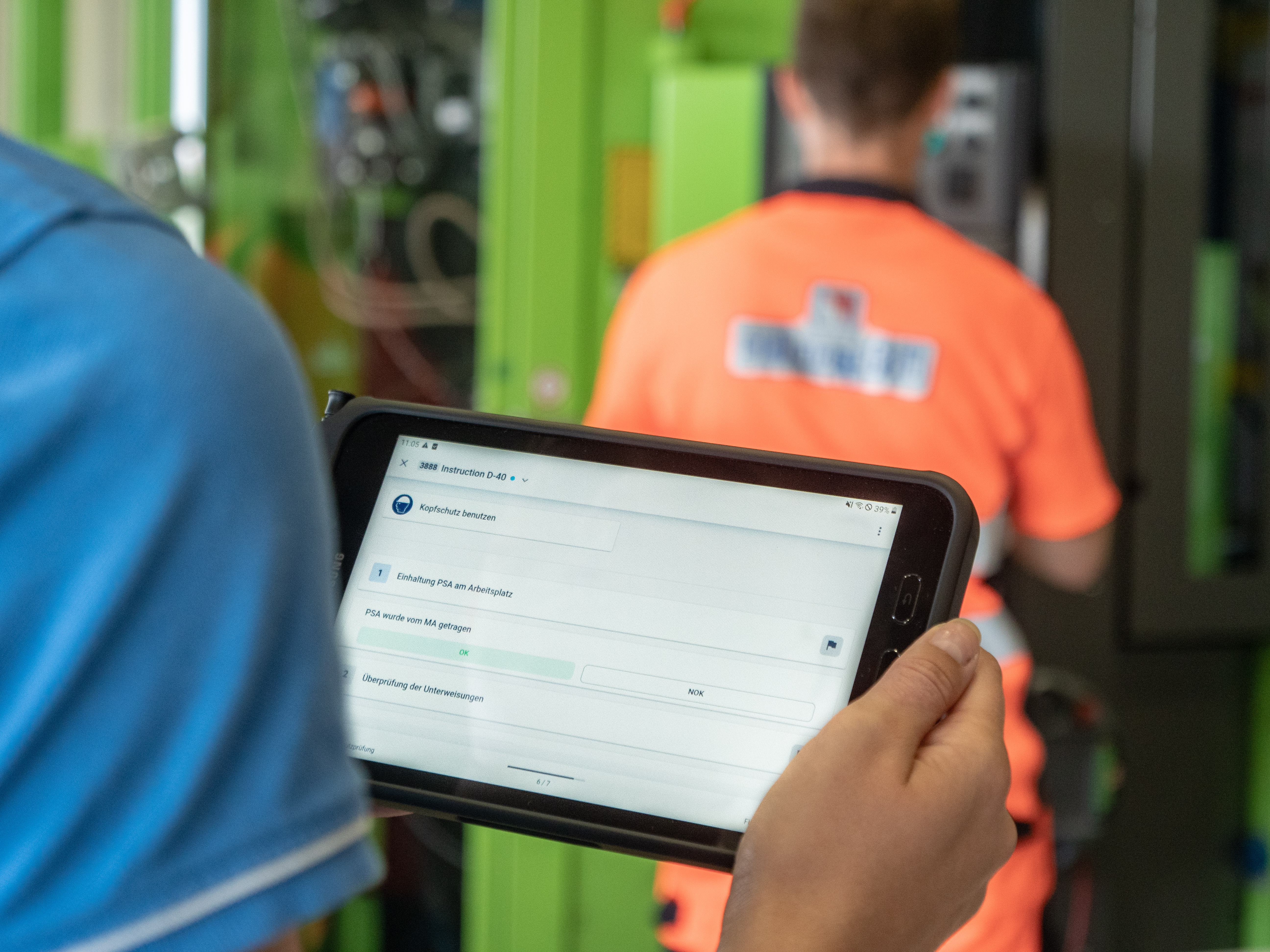

Improve your maintenance and audit processes to keep the availability of your machines and the proportion of good parts high.

Score points in external audits with fully documented shop floor activities and strengthen your audit security.

Case-specific work instructions enable information to be provided in a more understandable way. In this way, your employees receive the relevant information about what needs to be done when and how via interface or simple planning.

Reduced effort in the provision of information

Easily adopt customer-specific requirements

Reduction of training time by up to -67%

Give your maintenance teams the right tools to execute high-quality processes now and in the future, with Operations1.

Reduction of downtimes

Increased machine performance

Reduction of bad parts

Process progress and deviations are recorded directly digitally. Changes in processes and new solutions can be communicated to employees almost immediately.

Flexible and fast CIP

Live overview of progress on the shop floor

Easy sharing of globally relevant standards

+11%P OEE after 6 months and -23% mean-time-to-repair (MTTR)

Gain of +80% time savings and 50% quality control efficiency

Reduction of machine downtimes through automated maintenance planning

-60% downtine in international plants and savings of €250,000 per location

Use the exchange with our product experts to find out how you can benefit from Operations1.

Fill out the form and we will get back to you in a short time.