- +50% Inspection efficiency

- +80% Time saving

- -100% Manual effort

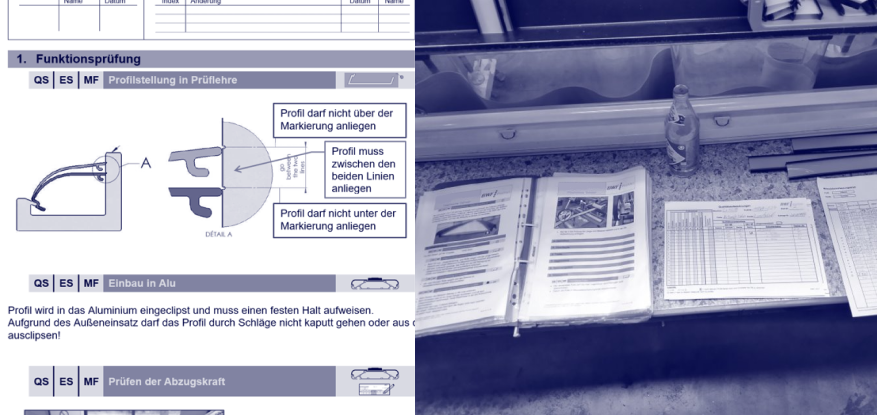

Although we are a modern company, we still used to work a lot on paper in quality inspection.

Status quo

BWF Profiles responds to individual customer requirements like no other company in the manufacture of plastic products. This means an enormously high number of variants and thus complex quality inspection.

Before the introduction of Operations1, BWF Profiles used to work with paper-based inspection instructions and checklists. This led to a high document creation effort as well as to a partially reduced process understanding.

Learn how BWF Profiles benefits from working with Operations1

Challenges

Until now, product quality was controlled with the help of laboriously compiled paper lists. The manual transfer, evaluation and subsequent archiving of the test results were also high cost drivers for the quality department.

In search of a solution to these complex challenges, Patrick Sched, Quality Manager, took the lead in initiating the collaboration with Operations1.

Implementation

The Operations1 software - including variant configuration and test cycle dynamization - was implemented within five months. BWF Profiles was supported by an experienced integration team from Operations1.

Using Rest API, the cloud software pulls product-specific data directly from SAP and makes it available in a structured way. Test instructions and checklists can thus be created variant-specifically and automatically.

Results

The creation of test instructions is now automated and order-related. Test instructions are created according to variants with just a few clicks in the software. As a result, BWF Profiles saves up to 80% of the time previously required for creating test instructions.

Operative employees are guided through the inspection process with comprehensible videos of the customer's installation situation. The result: less rework and scrap production. Inspection efficiency is additionally supported by inspection cycle dynamization.

Digitize your test instructions with Operations1

Let’s start a conversation

Would you like to know how the digitalization of your test instructions can be implemented with Operations1?

Arrange a non-binding appointment with our team. Our experts will be happy to advise you based on your individual use case!