Webinar recap: Digitizing the shopfloor in record time

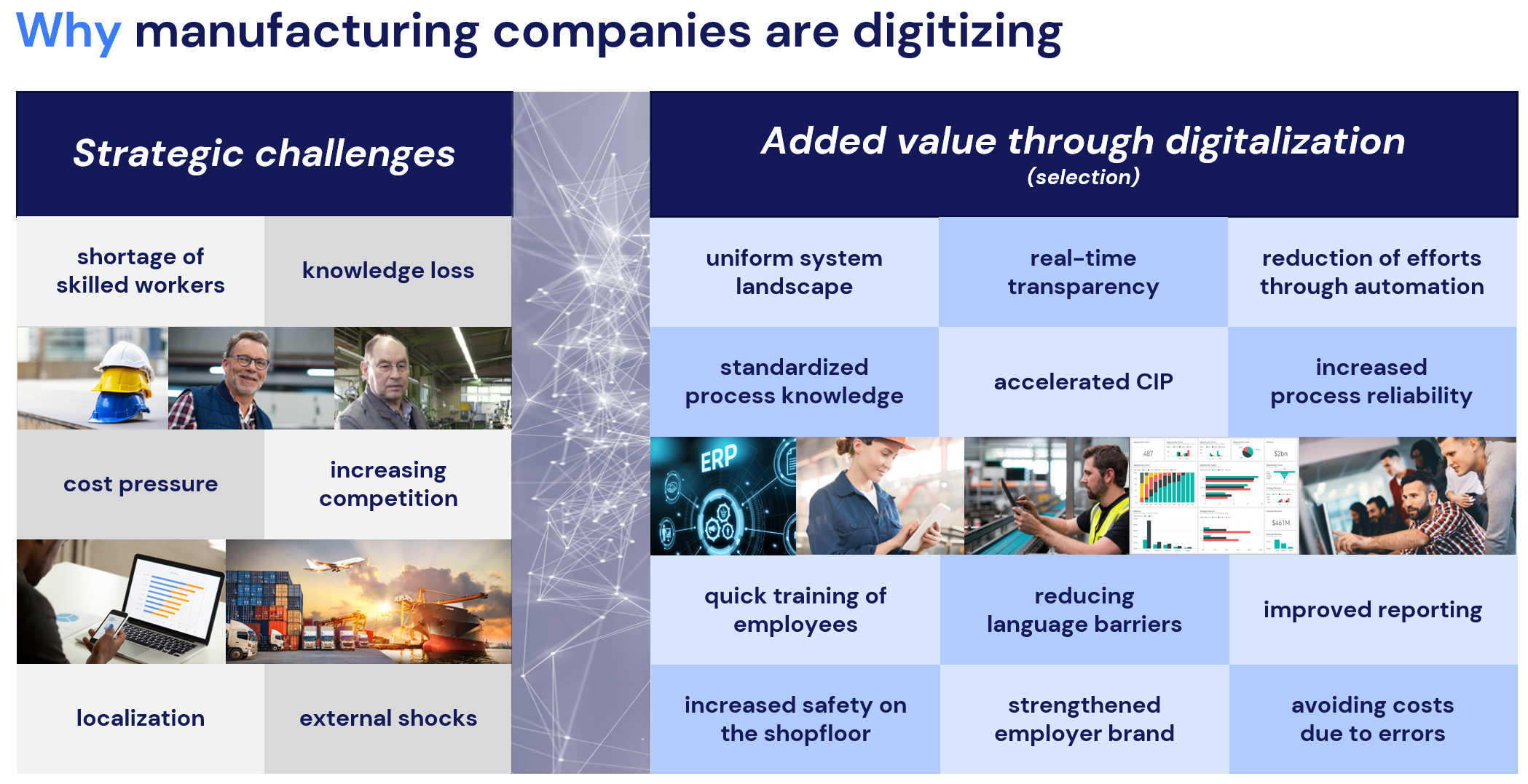

Quickly boost productivity - The demands on manufacturing companies are constantly increasing: rising cost pressure, more complex products, a growing shortage of skilled workers, and ever shorter innovation cycles. The shopfloor, i.e., the direct production level, is at the heart of this. But this is where traditional, paper-based processes quickly reach their limits.

Many companies are therefore faced with the question: How can they make the transition to a digitalized shopfloor without months of projects and high investments? The good news is that digitalization does not have to be complicated. With the right approach, productivity, quality, and process reliability can be increased in record time.

What this article is about

Find out in this recap of the webinar “Digitizing the shopfloor in record time”:

- Why digitization projects often seem so complex

- What is crucial for the success of shopfloor digitization

- What advantages digitization offers manufacturing companies

Why digitization projects often seem so complex

In many industrial companies, digitalization is initially perceived as a huge IT project. There are images circulating of multi-year implementations, confusing interfaces, and high costs. This perception often leads to projects not even being started or being delayed for a long time.

However, experience shows that the biggest stumbling blocks rarely lie in the technology, but rather in the approach. Typical hurdles include:

Overly theoretical planning: Instead of tackling specific shopfloor problems, complex concepts are developed that are divorced from reality.

Oversized systems: Many solutions are too complex for employees' everyday work and create additional effort.

Mental hurdles: Plant managers, division managers, or project managers worry too much about potential risks, dependencies, or resistance. Instead of simply getting started, they endlessly play out scenarios—unnecessarily delaying the first step toward digitalization.

Lack of acceptance: If employees do not immediately perceive the added value, digital tools will remain unused.

The key, therefore, is to take a pragmatic and user-oriented approach: small, quick-win steps instead of huge IT construction projects.

The digital shopfloor in practice

The key to successful digitalization is that it noticeably simplifies everyday work on the shopfloor. Technologies and tools must be effective where value is created—directly among employees. In practice, this means:

from paper-based processes and scattered Excel or Word documents,

towards digital, intuitive solutions that centrally bundle work instructions, checklists, or process documentation and make them available at any time.

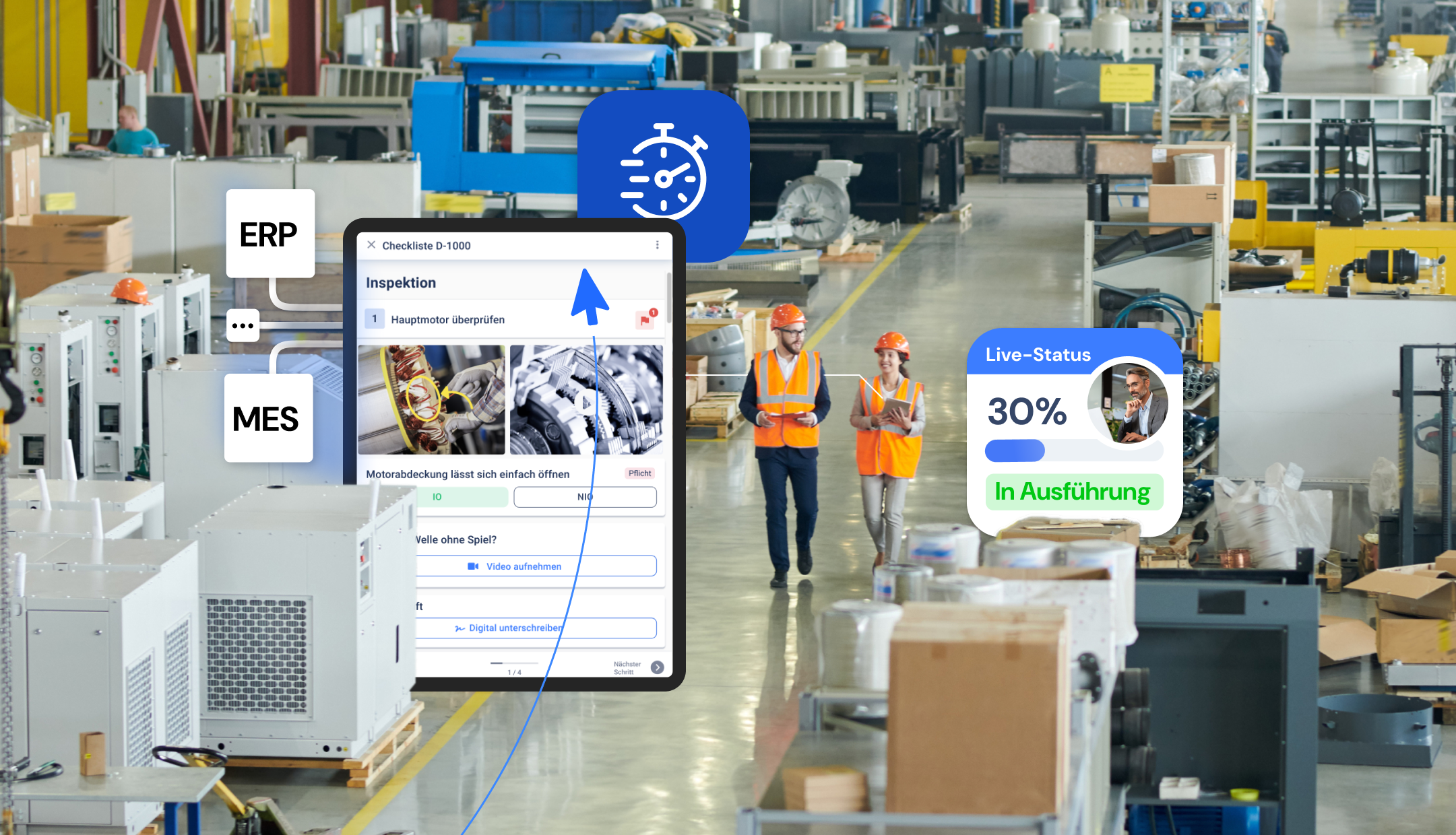

Another success factor is seamless integration into existing IT landscapes. Systems such as ERP, MES, or CMMS should be networked with the shop floor to ensure a continuous flow of information—from planning and production to quality assurance.

This creates a digital shopfloor that not only provides transparency but also enables operational excellence. At the same time, companies are able to respond more quickly to changes and future-proof their processes.

Ultimately, everyday life is the deciding factor: does the solution work directly at the employee's workplace? This is exactly where cloud-based platforms come in.

Elimination of paper, Excel, or Word documents,

replaced by digital, intuitive work instructions, checklists, and process documentation,

all centrally managed and available at any time.

End-to-end integrable platforms connect seamlessly with leading systems such as ERP, MES, or CMMS. This means that the shopfloor is not viewed in isolation, but rather as part of a continuous value chain—from planning to execution. For companies, this means operational excellence and future-proofing at the same time. After all, those who set up their processes digitally and modularly can respond much more flexibly to new requirements.

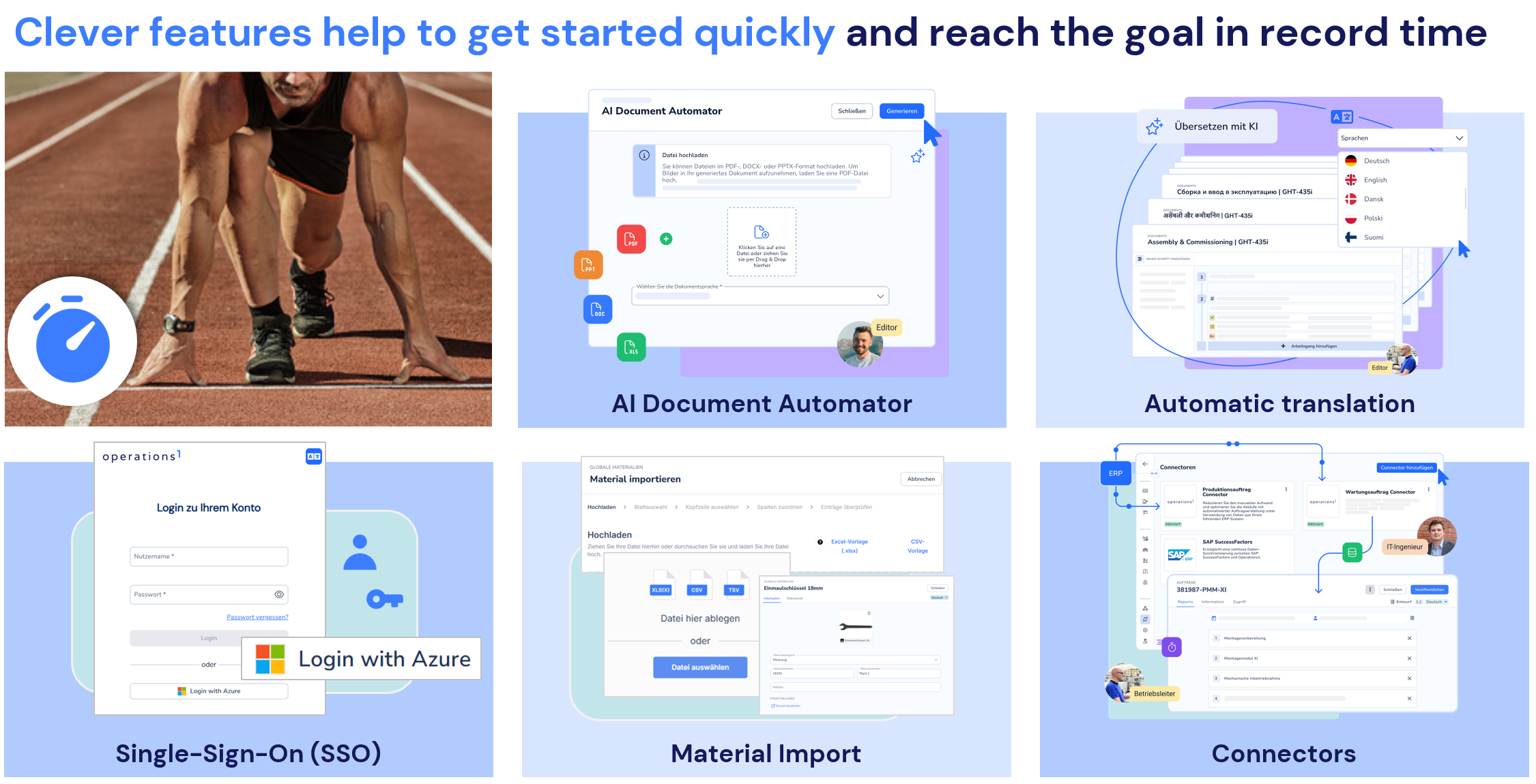

A digital shop floor is not a static project, but rather a continuous development. Therefore, make sure that improvements such as AI-supported features are continuously incorporated into the platform:

AI-assisted document creation: Work instructions can be created more quickly and automatically translated into multiple languages.

Modular maintenance: Changes to processes no longer need to be made individually in each document, but apply system-wide.

Connection to leading systems: Production data from, for example, the ERP system can be integrated in real time, increasing transparency and control.

The move to a digitalized shop floor is rewarding - even after just a short time.

Our regular discussions with manufacturing companies on the subject of digitization projects have made one thing clear to us: digitization enables companies to become productive more quickly, and employees feel the benefits immediately. Instead of creating additional complexity, shop-floor platforms simplify everyday work for shop floor employees and free up more time for value-adding activities.

Higher efficiency: Standardized, digitally available processes reduce search times, questions, and errors.

More transparency: Managers and teams have an overview of the current production status at all times.

Faster training: New employees can be deployed more quickly and productively with visual, easy-to-understand work instructions.

Fewer errors & greater reliability: Process deviations are documented, and standardized procedures ensure consistent quality.

Flexibility for the future: Process adjustments to products or markets can be implemented quickly and transparently.

Companies regularly report increases in productivity and a significant reduction in the workload for skilled workers — and one thing is certain: the digital shopfloor is becoming a competitive advantage.

Conclusion

Digitizing the shopfloor doesn't have to be complicated or expensive. Those who start pragmatically, consistently involve employees, and choose a platform that can be seamlessly integrated into existing systems will achieve noticeable results after just a short time. In record time, this creates a basis for operational excellence, future-proof processes, and motivated employees. Change does not begin with a mammoth project, but with the first concrete step. And this step is easier than many people think.

The recording of the webinar (German)

Book your personalised live demo now

Receive a customised live demo from one of our product experts – free of charge and with no obligation.

Digital work instructions for more efficient production

Complete documentation for maximum transparency

Video-based training for quick familiarisation

Markus Glotzbach

During his professional career, Markus gained deep insights at companies and large groups in different industries and knows the digitalization hurdles and problems on the shopfloor. Before joining Operations1, he studied International Management (MA) and worked in the Cloud Computing as well as SaaS telematics sector.