Future-proof production of high-quality machines and systems

Make your shop floor ready for the future. Paper folders are completely digitized. Your employees will only receive relevant information. You keep track of process progress.

Strengthen your production with Operations1

Increasing competitive strength

You can map customer-specific products successfully and cost-effectively with variant-specific work instructions.

Increased productivity and efficiency

Simplify information for your employees on the shop floor with digital step-by-step instructions.

High quality with increasing customer requirements

Reduce errors in processes and avoid unnecessary costs for scrap and rework with Operations1.

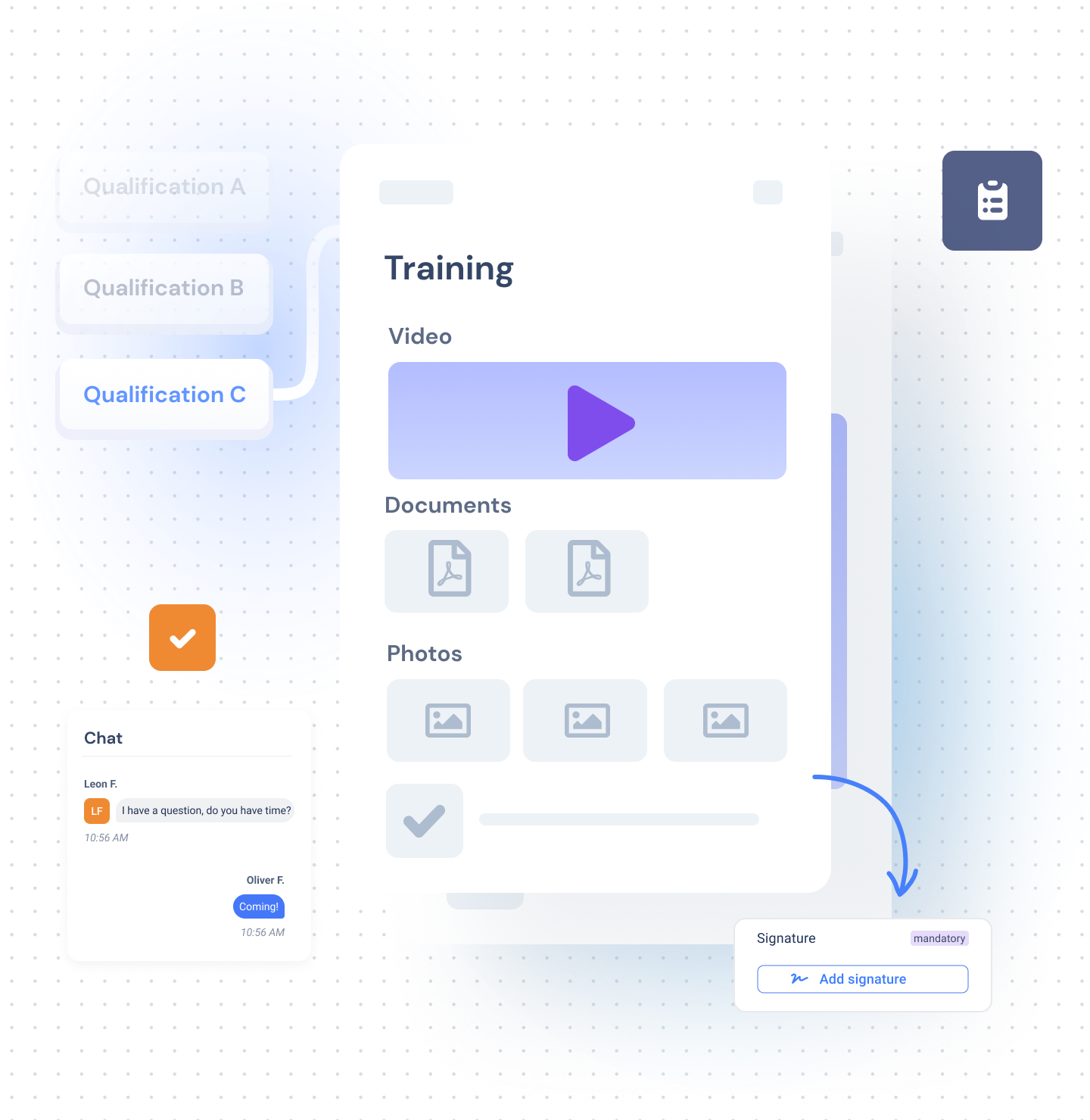

Fast training of employees

Multilingual, digital and multimedia work instructions are the new way of efficient employee training. Regardless of qualifications, new employees quickly become specialists.

Reduction of training time by up to 67%

Flexible deployment options for existing employees

Independent training of new employees

Customer-specific modularity from assembly to commissioning

With Operation1, you can implement variant-specific assembly instructions and test protocols. Use your full potential by connecting to the existing ERP- or ME-system. This way, your employees receive the information that is relevant to them at the right time.

Reduced complexity for employees

Increased process reliability for flawless tests

Up to -67% effort in test documentation

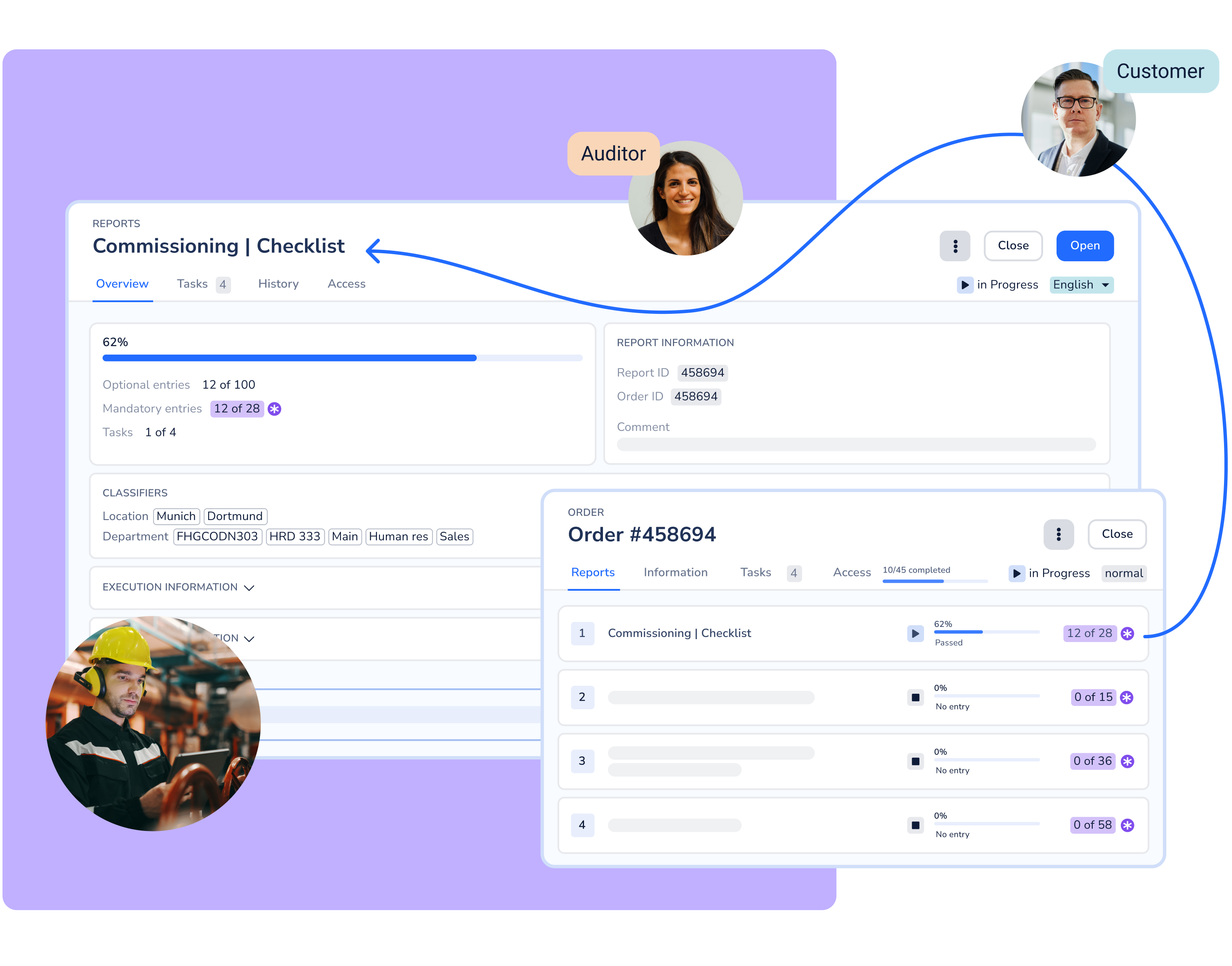

Complete documentation across all processes

Automatically generated reports with images, videos, serial numbers and much more help your employees through the entire value chain. Auditors and customers receive relevant information as quickly as possible.

Reduction of manual effort through automatic reports

Up to -75% effort for traceability

Increased traceabillity for customers

Assuring quality during assembly

Assure your quality level with standardized and understandable assembly instructions. The option for in-line quality control reduces downstream efforts.

Early detection of possible errors

Error reduction of up to -25%

Order-specific assembly instructions for greater efficiency

How other machine and plant manufacturers benefit from Operations1

Soudronic

180,000 € savings per year and increase in process reliability

Zünd Systemtechnik

+10%P additional increase in delivery quality and significant time savings

KraussMaffei

-67% documentation effort and savings of 1,200 working hours per year

Nabertherm

Strengthening quality assurance and reducing the effort involved in generating test reports

Brückner Maschinenbau

Savings of 2,000 hours of travel time and +13% increase in employee productivity

Schedule a meeting

Use the exchange with our product experts to find out how you can benefit from Operations1.

Fill out the form and we will get back to you in a short time.