Efficient production of high-quality goods

Digital checklists help you maximize your production efficiency and drive growth: Reduce your unit costs and ensure compliance with growing regulatory requirements.

Sustainable strengthening of your production

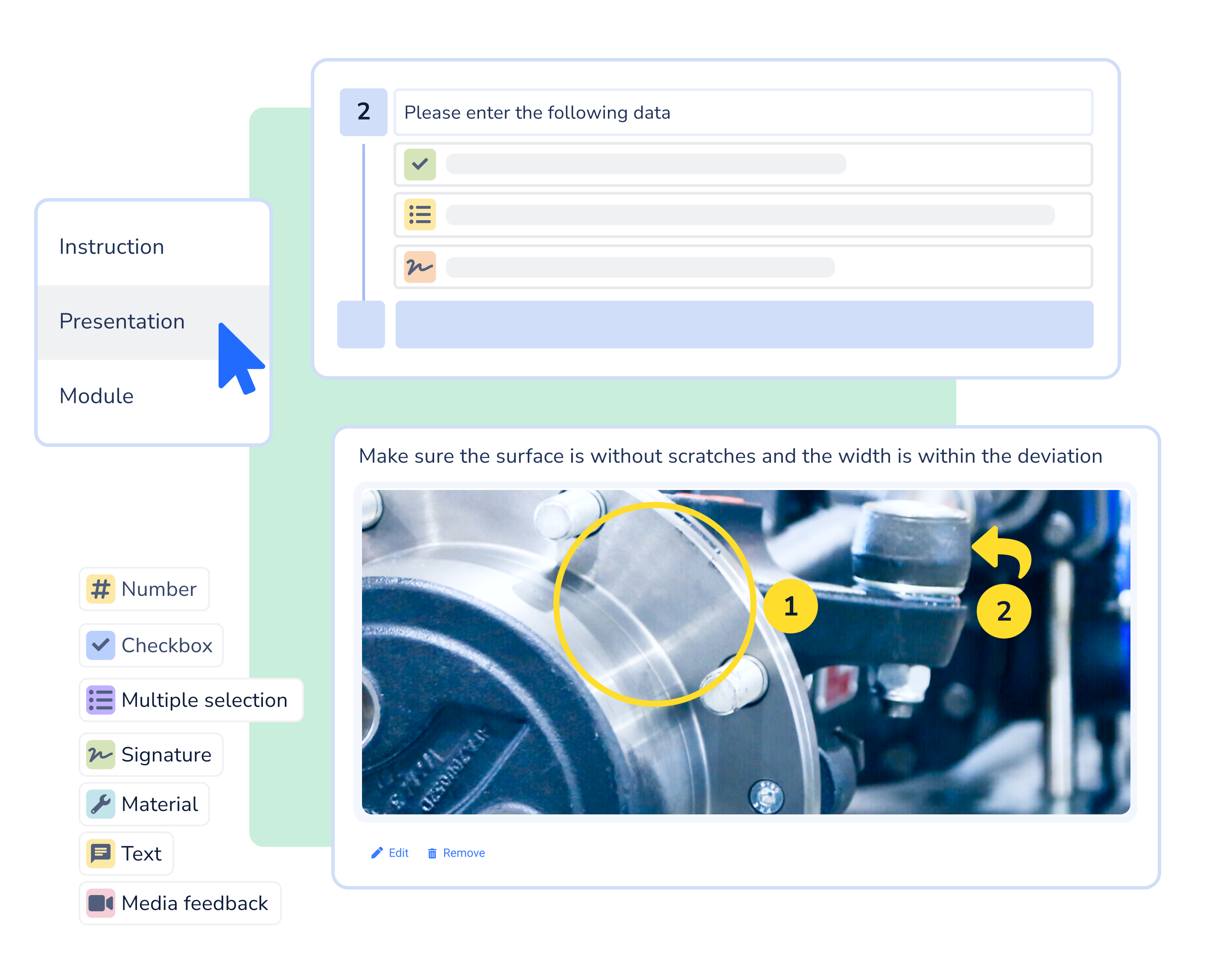

Process standards for all plants easily established

Standardize your process quality with digital checklists and make them available to all your factories digitally and directly.

Improved OEE for consistently high volumes

Machines must not be allowed to stand still unplanned. Digitized maintenance processes enable you to successfully improve your maintenance KPIs.

Increased proof for auditors

With Operations1, you can strengthen your reporting on compliance with regulatory guidelines through digital documentation.

Optimized maintenance for reliable production

Simplify the work of your maintenance teams and reduce costs due to machine failures. Enable autonomous maintenance by machine operators with the help of easy-to-understand step-by-step instructions.

Increasing the quality of maintenance processes

Reduction of unplanned machine downtimes

Reliable just-in-time production

Continuous improvement easily integrated

Give your employees a tool with digital checklists to document observations and findings directly using images and videos. CIP measures can thus be implemented more quickly.

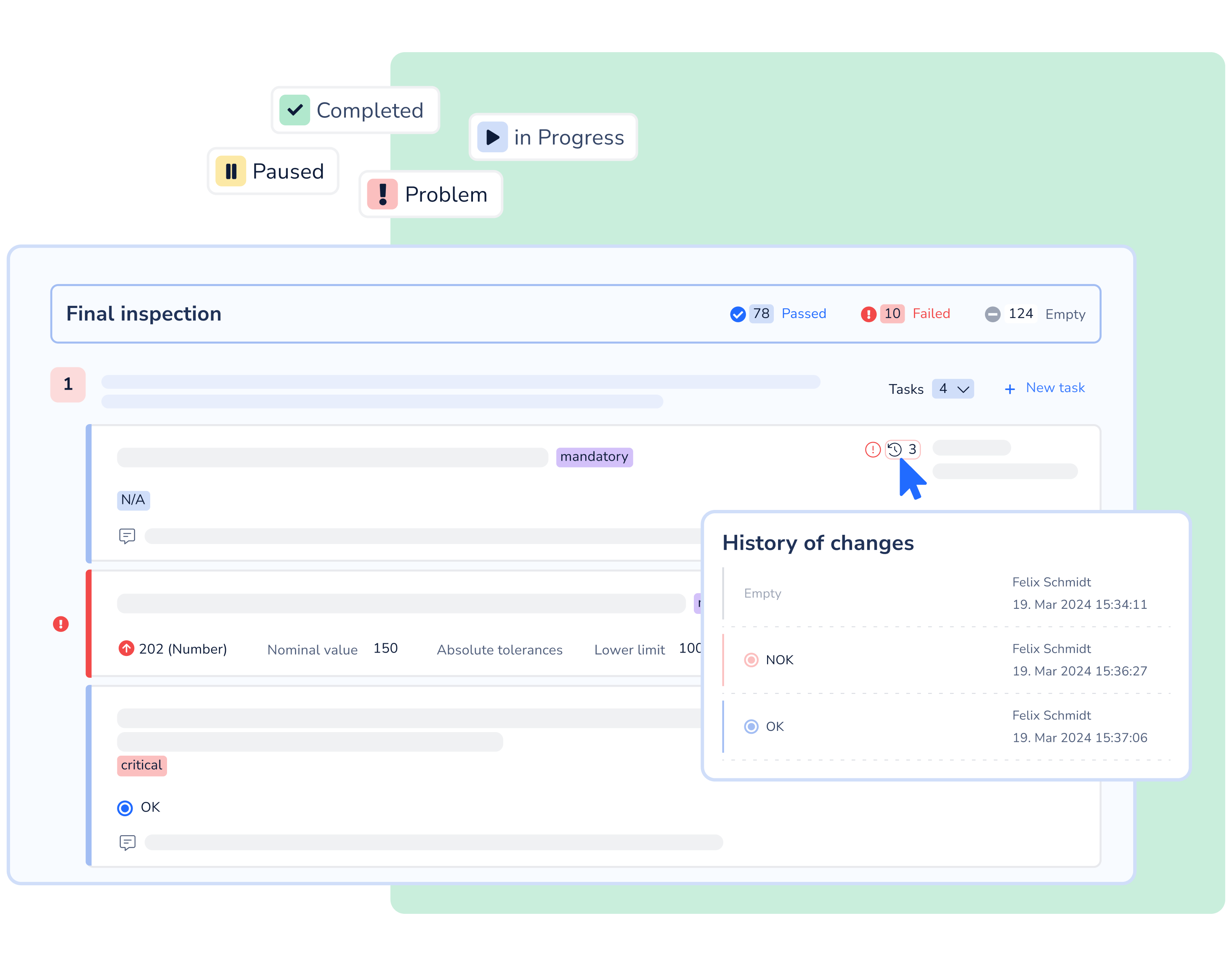

Quickly improve protocols and checklists

Share best practices easily, across locations

Easily traceable change histories

Increase flexibility and share knowledge quickly

Multilingual digital instructions enable employees to be trained more independently. Whether it's safety briefings, Gemba Walks, 6S audits or maintenance: process knowledge can now be conveyed in a multimedia, understandable and process-reliable way.

Reduction of training time by up to -67%

Reduction of the workload for trainers/mentors

Flexible deployment of employees in different areas

How other manufacturers leverage potential with Operations1

Hirschvogel

-60% downtine in international plants and savings of €250,000 per location

Schwäbische Härtetechnik Ulm

Reduction of machine downtimes through automated maintenance planning

Oetiker

+11%P OEE after 6 months and -23% mean-time-to-repair (MTTR)

POLIPOL

-67% shorter training time and savings of €2.2 million per year

Schedule a meeting

Use the exchange with our product experts to find out how you can benefit from Operations1.

Fill out the form and we will get back to you in a short time.