- -70% Training time for new employees

- -48%P Error rate

- +300% Output within 12 months

Operations1 enabled us to digitize all production-related documentation.

Director of Operations, Quantum-Systems GmbH

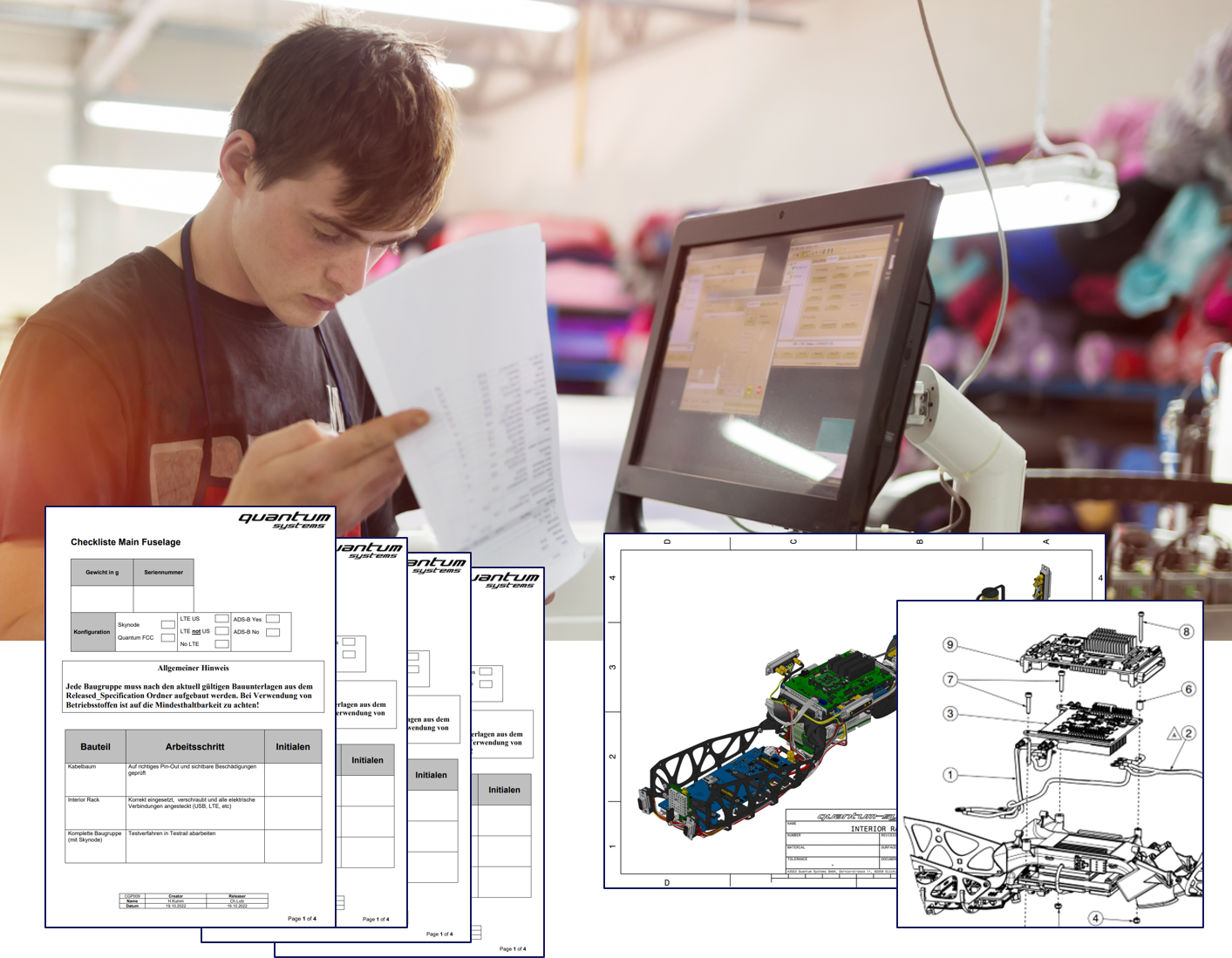

Status Quo

With increasing growth and a high order backlog, paper-based processes and individual knowledge quickly reached their limits.

To enable the rapid global ramp-up of new production sites, Quantum Systems defined clear goals: digitizing process-related steps, establishing scalable knowledge transfer, and ensuring consistent quality through standardization and greater process reliability.

Be inspired by the insights of Quantum-Systems GmbH's success story

Challenges

Production was based exclusively on the experience and knowledge of employees

Documentation was hardly available or paper-based

Slow training of new employees using a mentoring system

Test procedures and checklists were kept manually on paper

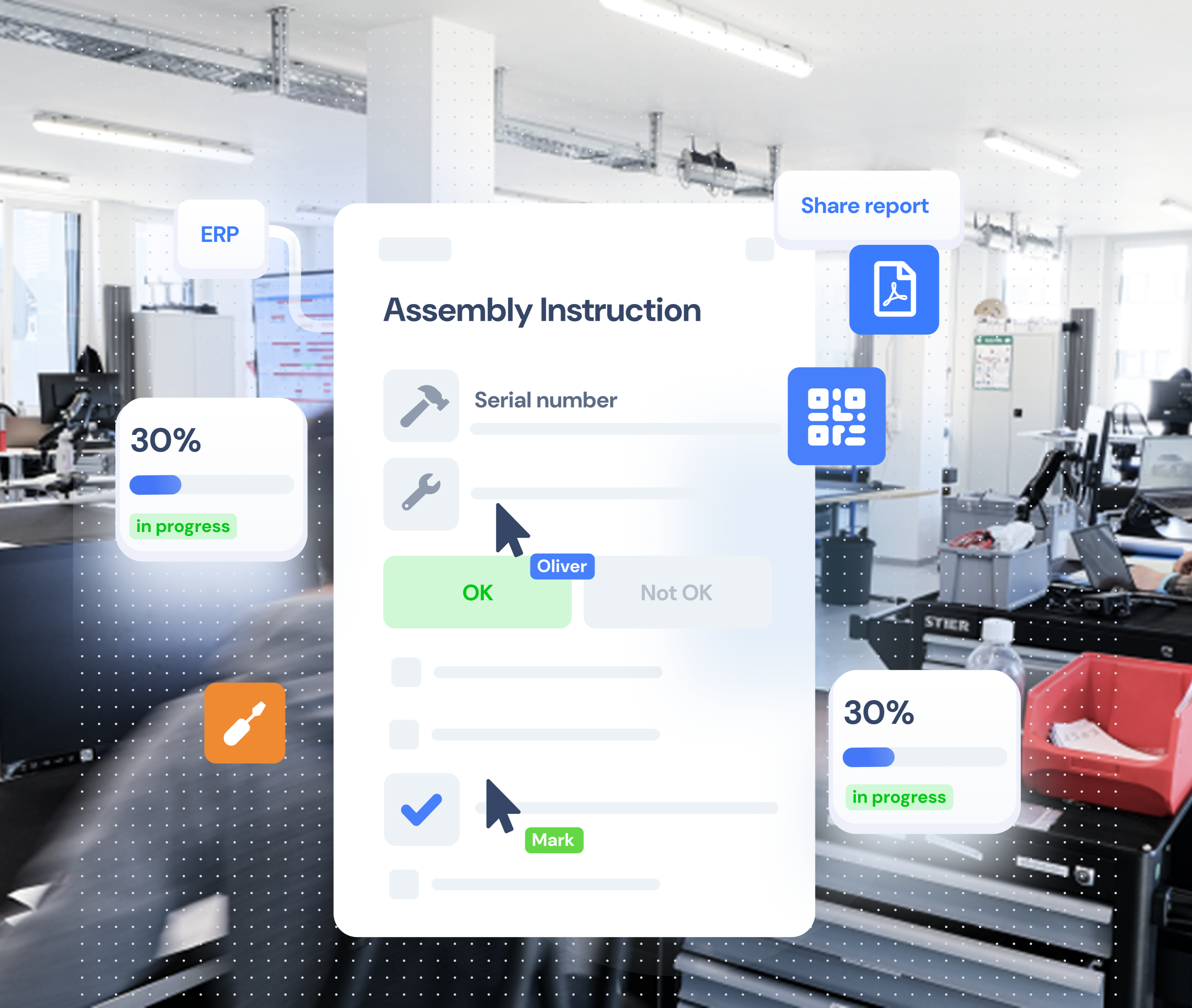

Introduction of Operations1

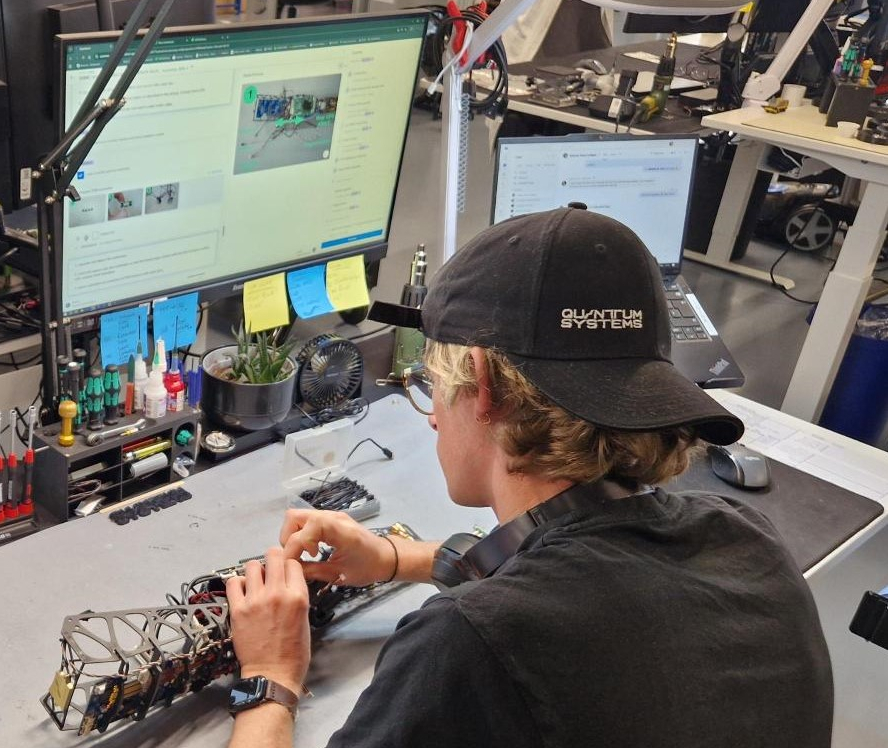

Quantum Systems began its digital transformation in the assembly department: instead of keeping the knowledge of experienced employees hidden in their heads, it was transferred into digital work instructions with images, videos, and interactive elements. This provided both new and experienced employees with clear step-by-step guidance that gave them confidence and simplified processes.

At the same time, integrated serial number recording strengthened seamless documentation and traceability throughout the assembly and testing process—a crucial component for quality and scalability.

Results

Operations1 is now embedded throughout Quantum Systems' entire value chain—from supplier integration and quality assurance to assembly and shipping to global rollout templates.

The visually supported work instructions reduced the training time for new employees from 1.5 months to 2 weeks. Mandatory interactions increased process reliability and reduced the error rate from over 50% to less than 2%.

Thanks to its multilingual capabilities, Operations1 is now used in more than five plants worldwide, ensuring international quality standards and comparability between locations.

The recording of the webinar with Quantum Systems (German)

Book your personalised live demo now

Receive a customised live demo from one of our product experts – free of charge and with no obligation.

Digital work instructions for more efficient production

Complete documentation for maximum transparency

Video-based training for quick familiarisation