Digital set-up instructions: Reduce set-up times, ensure quality

Standardised, digital set-up instructions for maximum machine availability, quality and flexibility - independent of location and employee

Reduction of set-up time

Reduction of rejects & costs

Ensuring product quality

Typical challenges during set-up

Inefficient processes

Long set-up times and machine downtime due to lack of standardisation

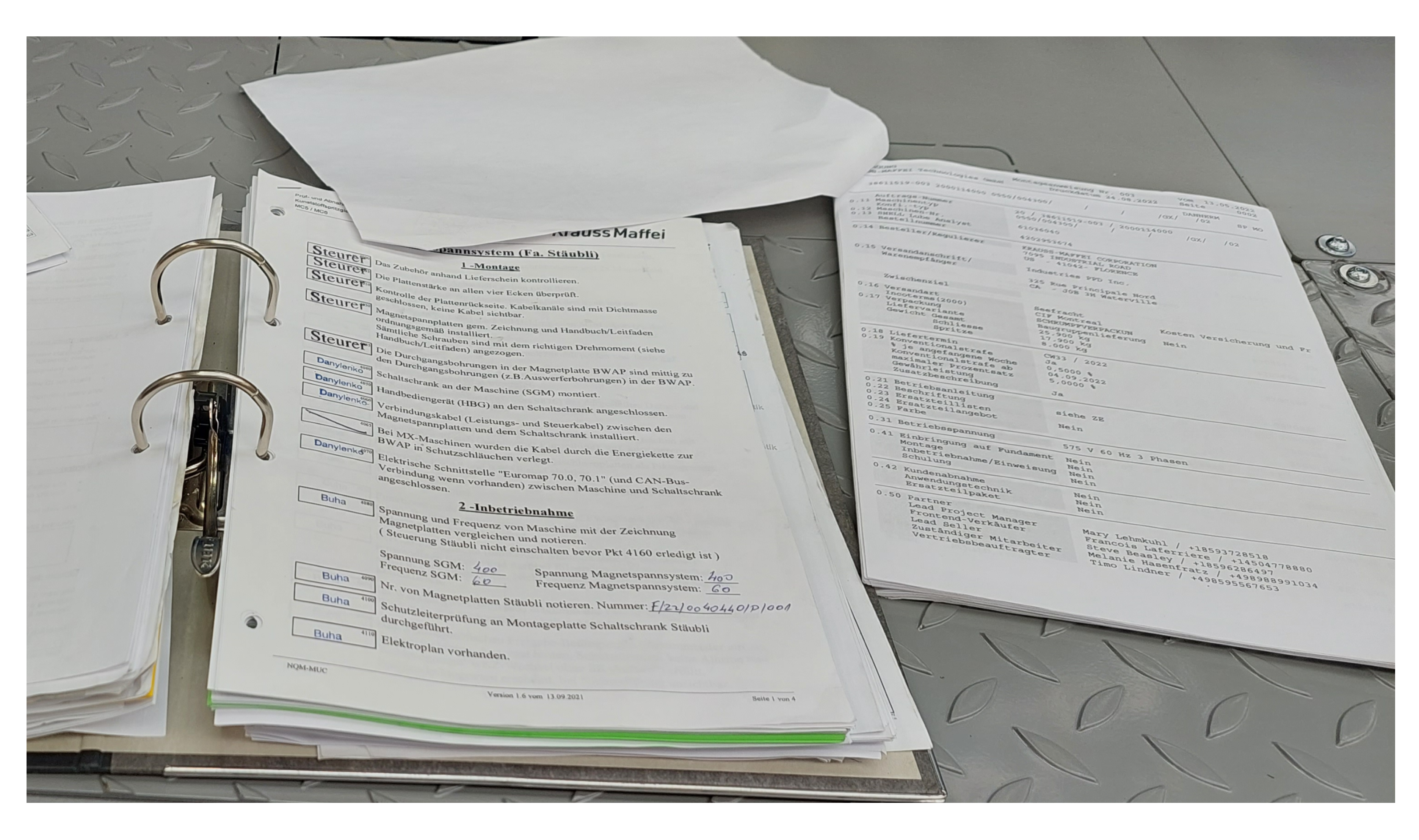

Paper-based set-up instructions are incomplete or outdated

Lack of process reliability

Incorrect set-up leads to quality problems & scrap costs

No clear traceability of responsibilities and approvals

High training effort

New or unskilled employees require long familiarisation phases

Expertise is often only stored in the heads of experienced employees

Process reliability & standardisation

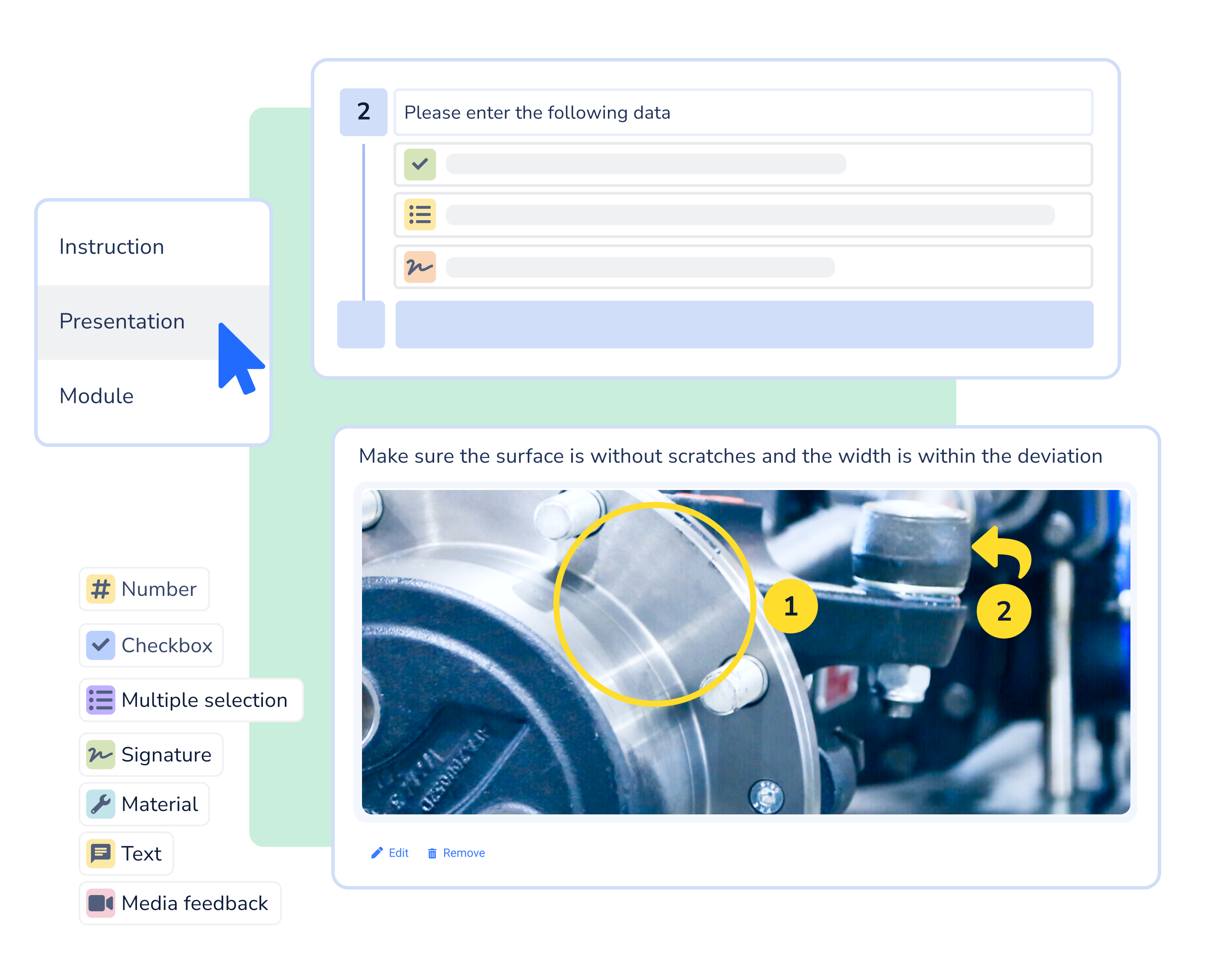

Interactive, guided set-up instructions with checklists & IO/NIO queries

Standardised processes for all machines, products and locations

Digital approvals and automatic time stamps for full traceability

Faster set-up processes & higher availability

Reduction of machine downtime thanks to structured processes

Fewer queries and corrections thanks to clear visual instructions

Proven by customers: +5 %P machine availability, +11 %P OEE

Independence of location & qualification

Multilingual, role-based content for global use

Even unskilled employees can quickly become productive without lengthy training

Flexibilisation of employees through intuitive worker guidance

Schedule a meeting

Take advantage of our team's many years of experience and get in touch with our product experts.

Free exchange on your individual use case

Best practices directly from practice

Presentation of solution approaches by Operations1