Modular documents - mastering variant variety with modules

Keeping a high number of variants under control with reduced effort

Say goodbye to maximum lists and provide your employees with variant-specific documents for their daily work without the need for interpretation.

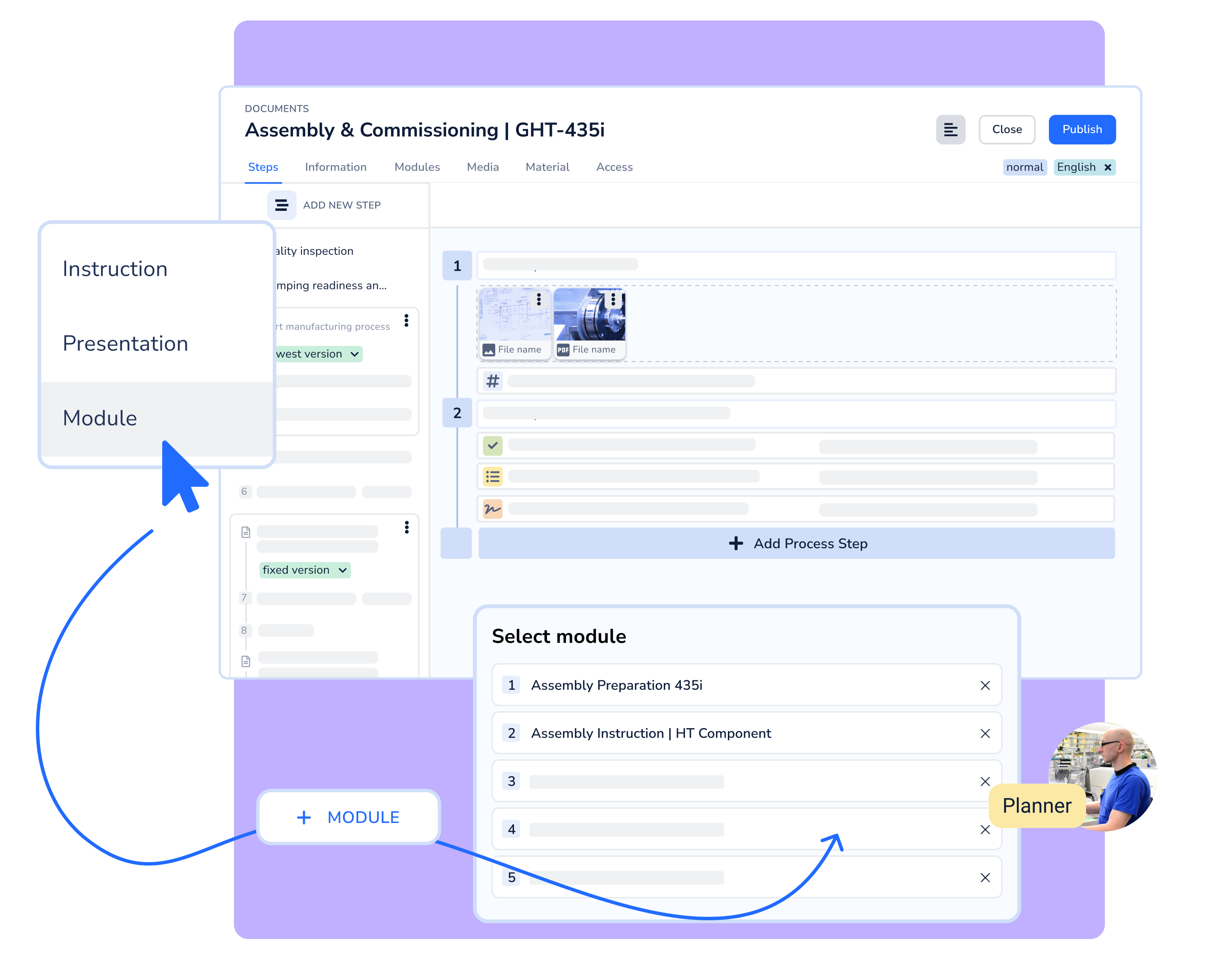

Take advantage of digital work instructions and checklists by adding existing documents as sub-documents or modules. This reduces manual administration work and you also benefit from context-based documents.

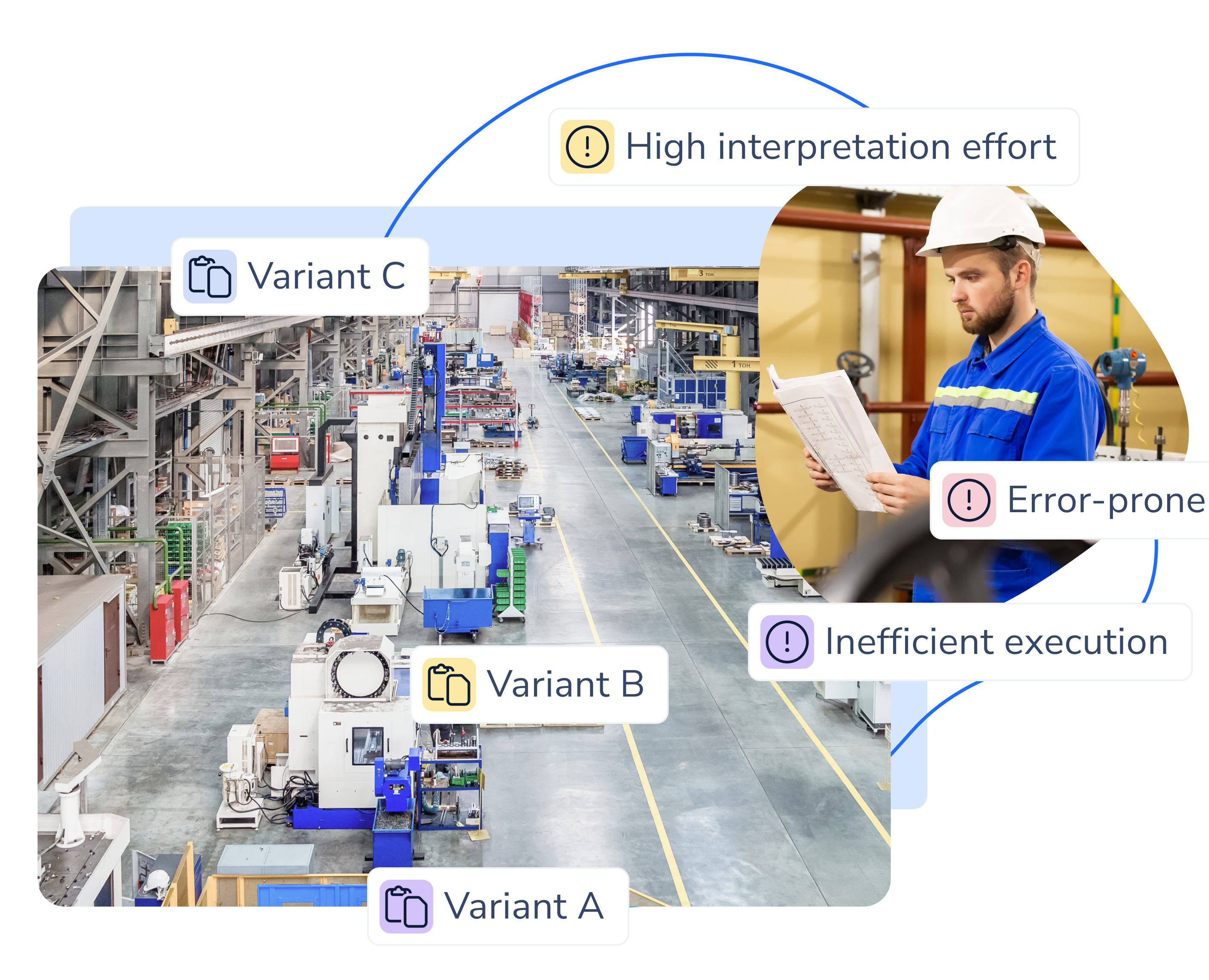

High effort and complexity

Regardless of whether you offer your customers individually configured products or have to maintain a machine park with many variants: In the operational process, variants mean detail-specific tasks for your employees. In paper-based processes, maximum lists are a panacea, but maximum lists have some disadvantages:

High manual management effort for maximum lists

High interpretation effort for your employees

High potential for errors when checking tasks

When variant diversity is no longer a problem

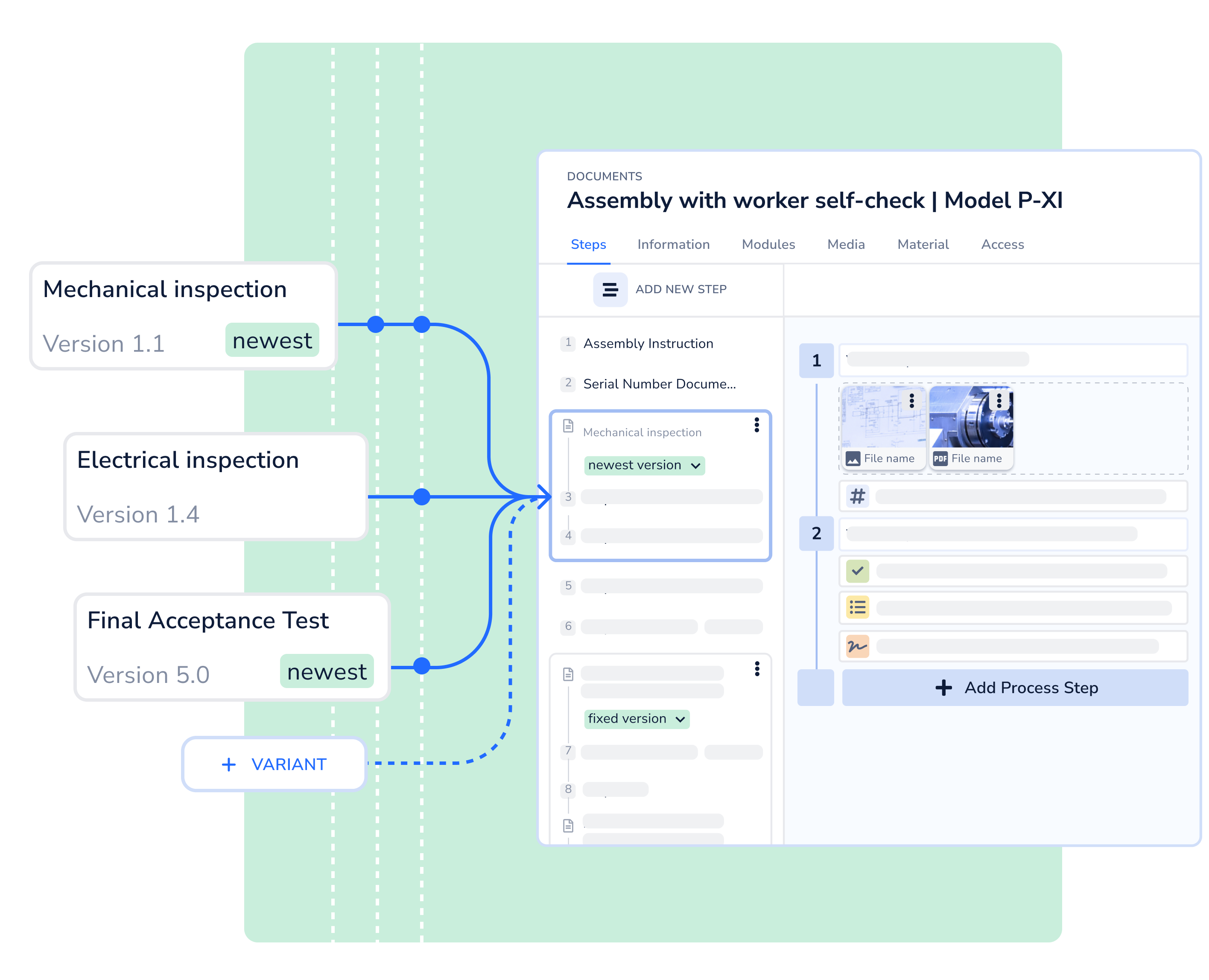

Modules

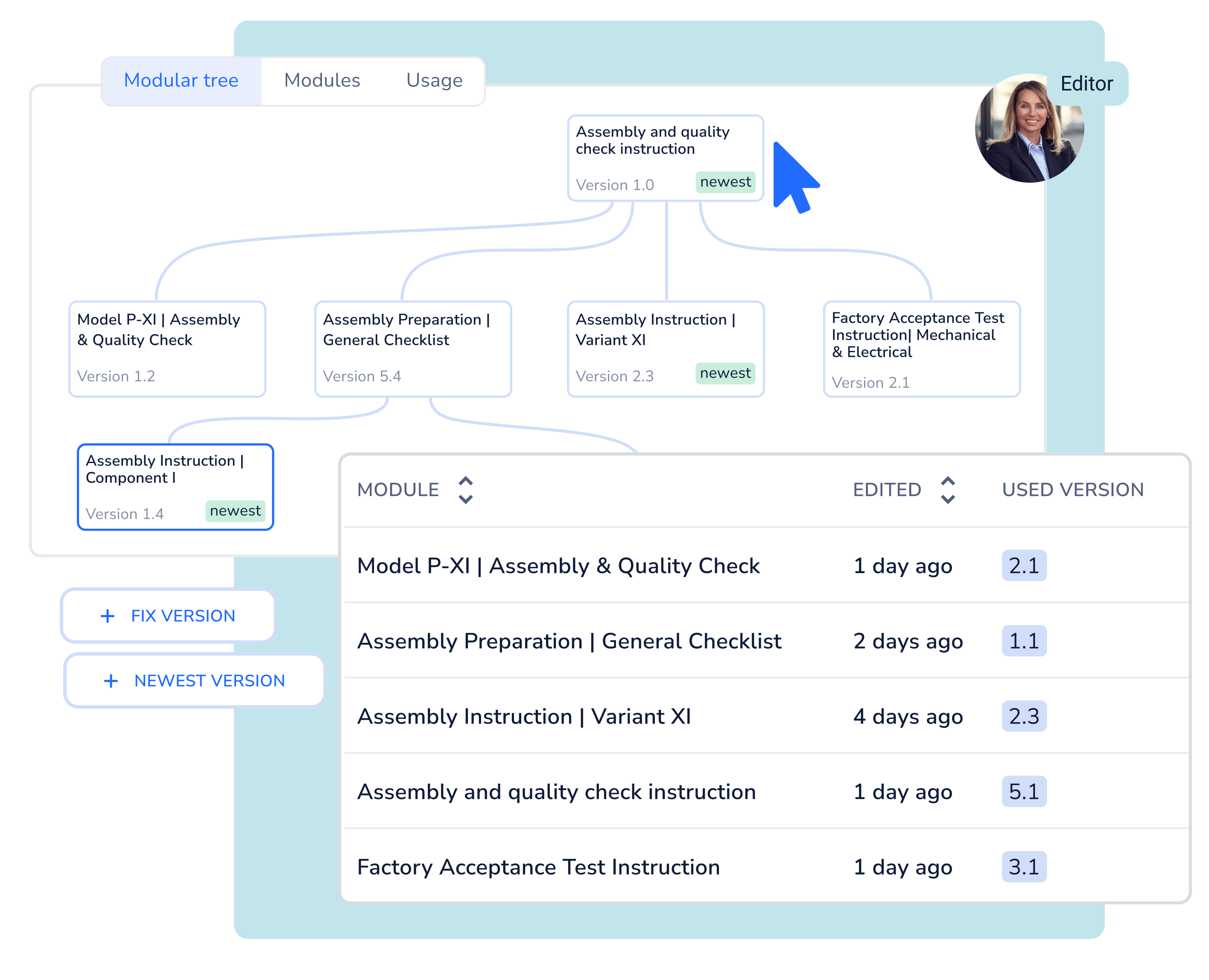

Use existing documents as modules in a digital work instruction, checklist, etc.

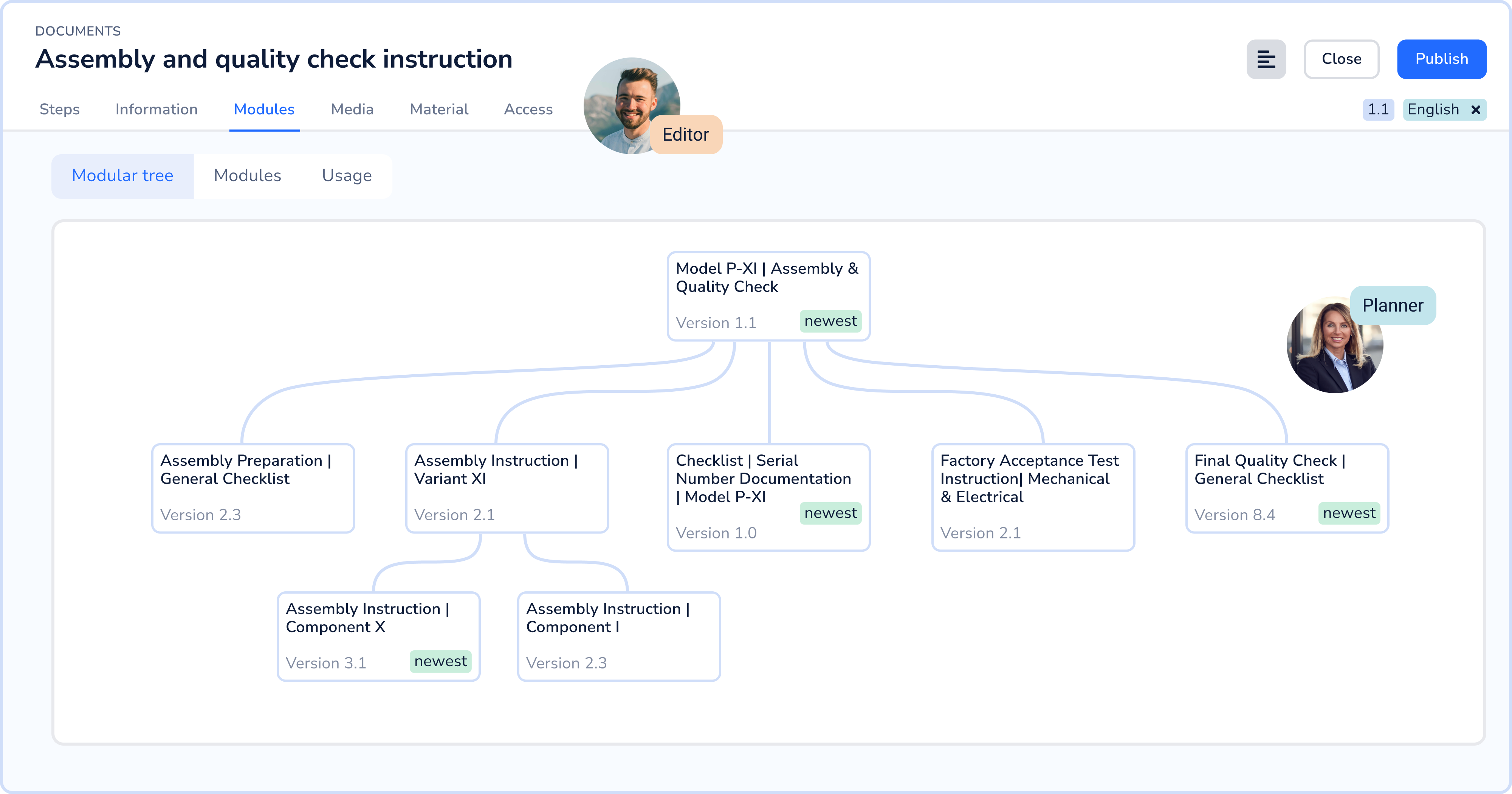

Module tree

See at a glance how documents are linked to each other.

Module usage

Always have an overview of which modules in which versions you are using in a document.

1,000 documents updated with one click

Do not update identical information, work steps or documentation steps for different product or machine variants in the individual document. Use a document as a module for mapping identical content in several documents.

Identical content maintained and updated centrally

Reduced effort and time savings

Increased process reliability

Always keep an overview

In various overviews, such as the module tree, you can see in which work instructions and checklists you use which modules with which module version.

Complete overview of the modules used

Simple tracing of module assignments

Used module version immediately visible

Get a handle on variant diversity with ease

Contact us now and take the first step towards digitizing your employee-led processes with us.