Leading companies use Operations1 for assembly instructions.

The more complex the technical system or machine, the more time-consuming the assembly documentation. Operating instructions, information on commissioning, technical drawings,

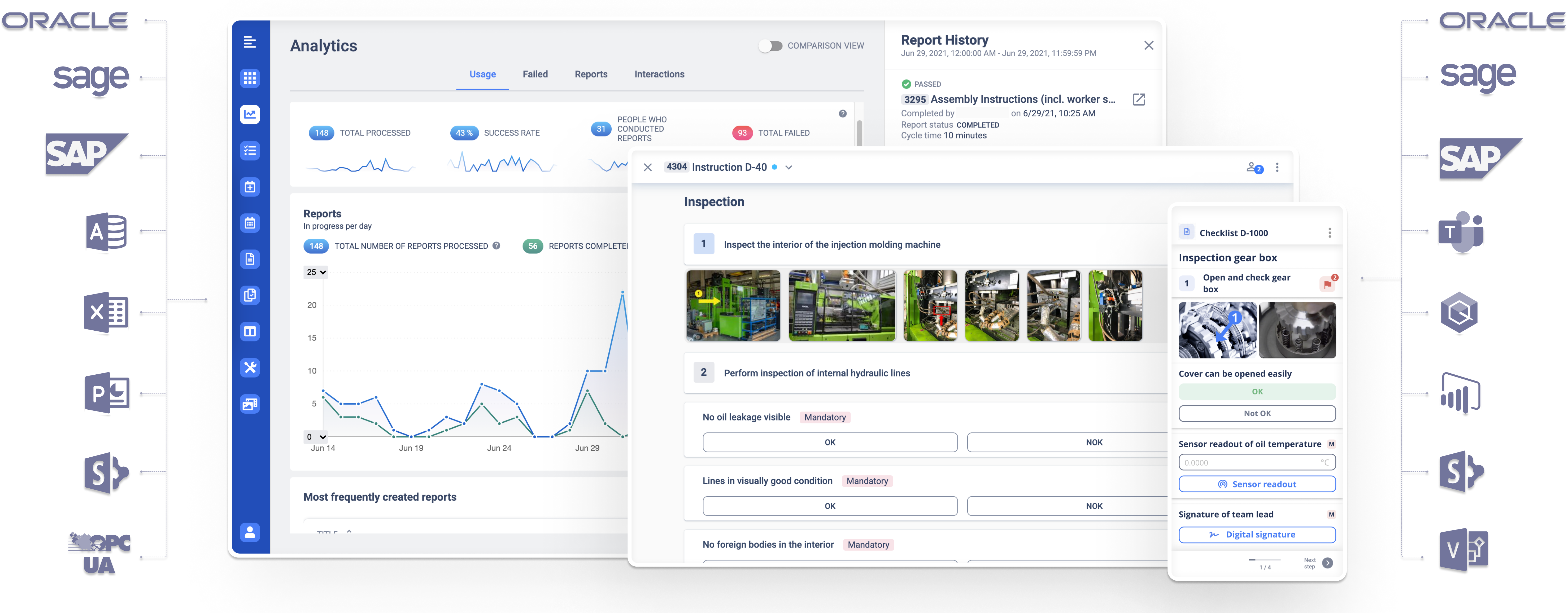

test reports, instructions for maintenance, care and servicing, and many other accompanying documents have to be created. Excel, PowerPoint and Word are not enough to successfully manage this effort; they even act as complexity drivers. With the help of digital assembly instructions, the creation of documents is 95% faster.

With the help of image- and video-based assembly instructions, setup and ramp-up times can be significantly reduced. Production relocations to new sites, disassembly of large equipment for transport and reassembly at the customer's site can be carried out reliably and quickly thanks to digital knowledge transfer. With Operations1, digital assembly instructions can also be made available in multiple languages without additional effort, and all documents relating to the assembly process are stored at one point of truth instead of in different data silos.

The time-consuming creation of complex assembly instructions with word processing programs such as Word leads to quality risks in the assembly process. With digitally supported worker guidance, assembly instructions can be directly linked to digital inspection reports. Workers are guided intuitively, step by step, through the assembly process with the help of photos, videos and graphics. Each step can be marked as "completed" and logged at the same time. Based on this assembly log, a maintenance plan for the plant can be created or it can be used for possible repairs. At the same time, automatic archiving of the assembly documentation enables transparency and revision security.

With Operations1's leading platform, you digitally map assembly instructions end-to-end: from the creation of assembly instructions, reliable worker guidance through the respective work steps to the evaluation of the assembly process. Connect Operations1 to your inventory systems such as ERP or MES and evaluate the collected data in BI tools.

In an initial kick-off meeting, we jointly develop a target image for your company and plan the next steps. As soon as you have filled out the contact form, we will contact you with a proposed appointment.

During this meeting, we will present the software and the functionalities that are particularly relevant for you using an individual live demo.

No-code editor Create your assembly instructions with drag-and-drop and choose from various interaction options

Integrated inspection instructions Use checklists and inspection instructions in an assembly document and increase comprehensibility with images and videos

Version control & sharing Share documents digitally. All key documents retain the same ID across versions, enabling consistent analysis

Change notifications Inform employees at the beginning of the assembly process with change notifications. Ask employees for confirmation.

Multilingualism Create your assembly instructions in all common languages. You can even work on the same document in different languages at the same time.

Images and videos Include images, videos, and graphics of target conditions in your instructions. Edit images directly to highlight specifics in the assembly process.

There are many reasons to choose Operations1. The reasons most often cited by our customers are these.