The key steps of commissioning a machine (also known as "start-up") are:

Installation: This involves physically setting up the machine and connecting it to the necessary power and utility supplies.

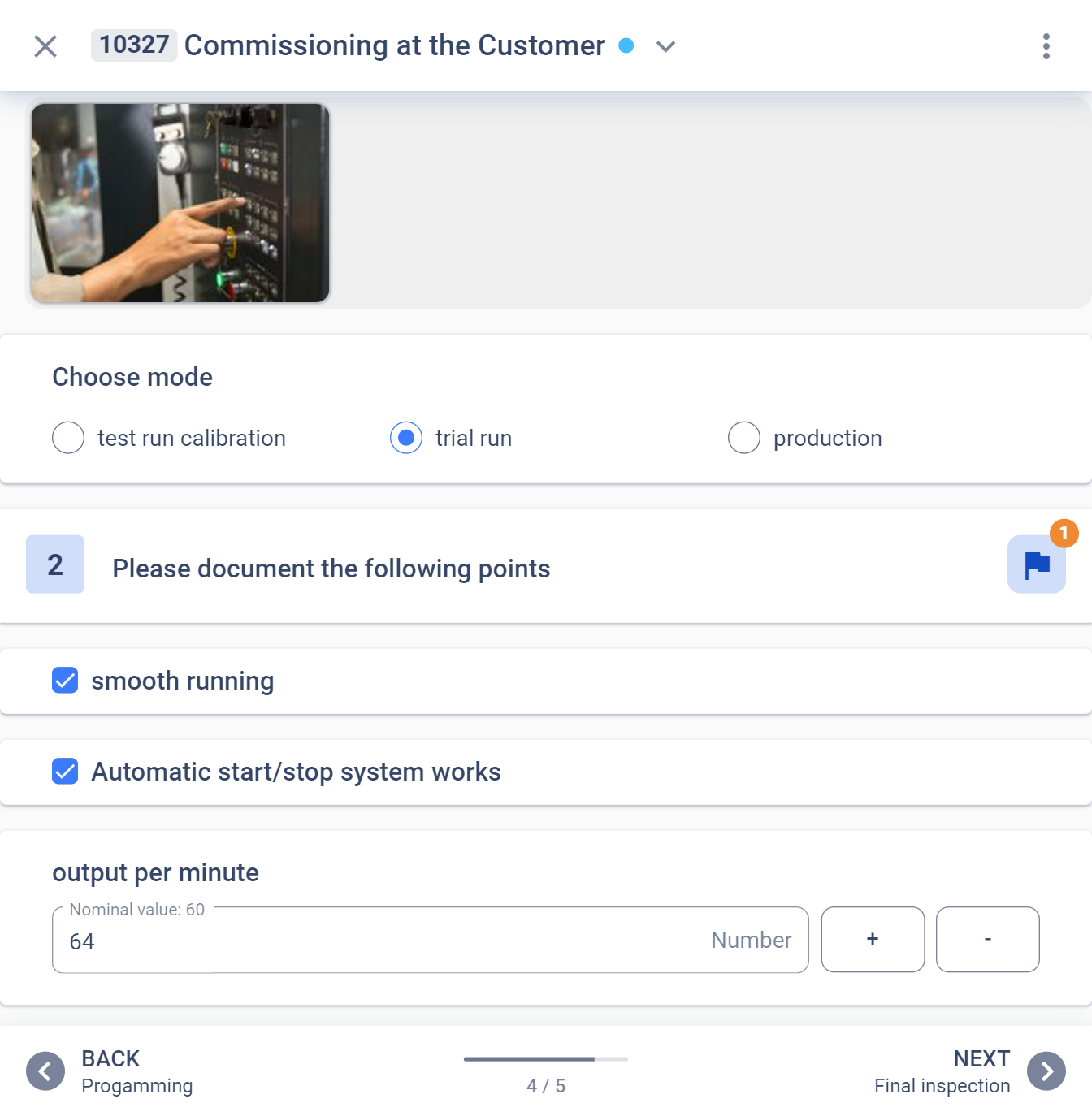

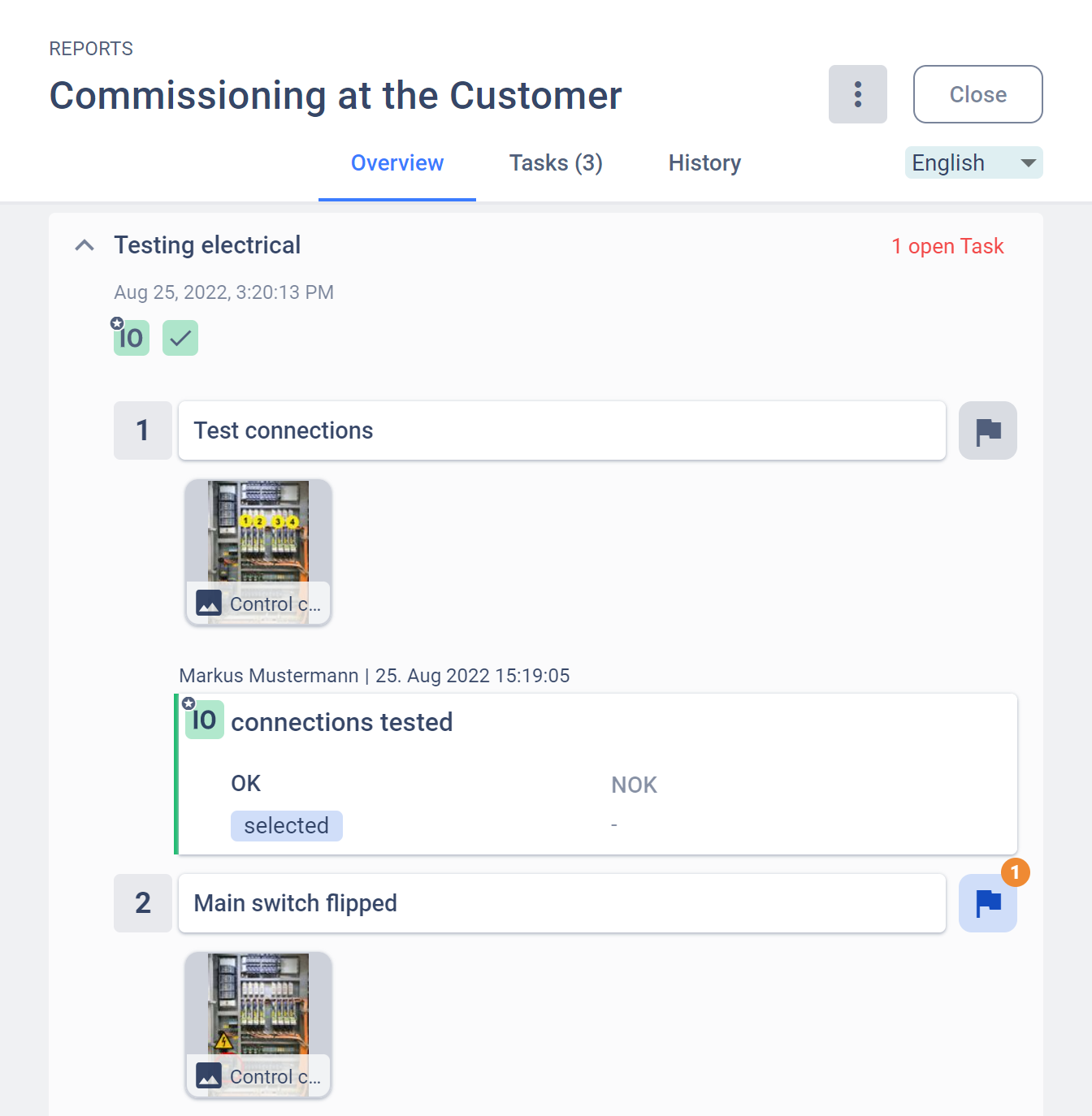

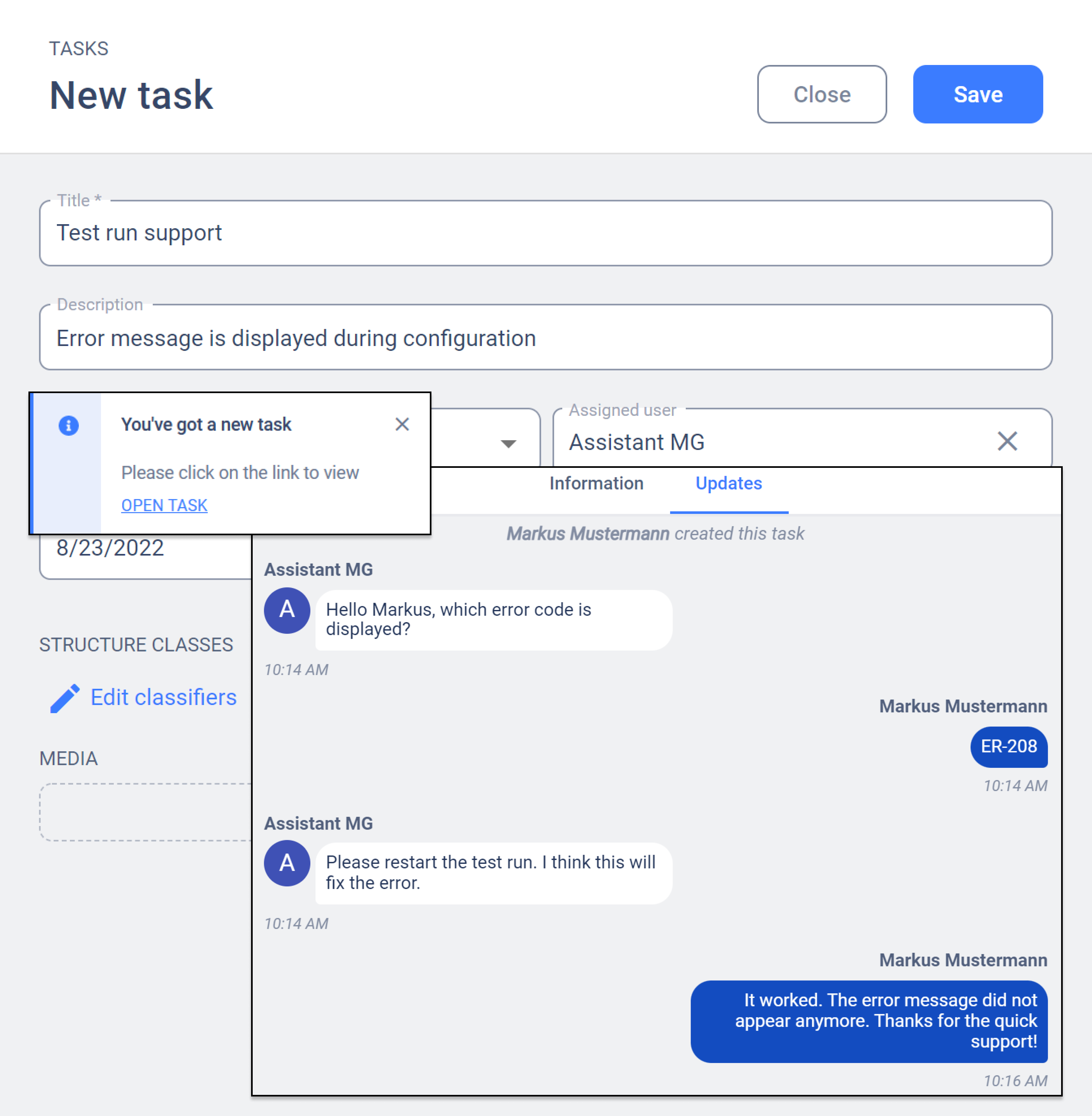

Function testing: The machine is tested for functionality and performance to ensure that it meets specifications and is operating as intended.

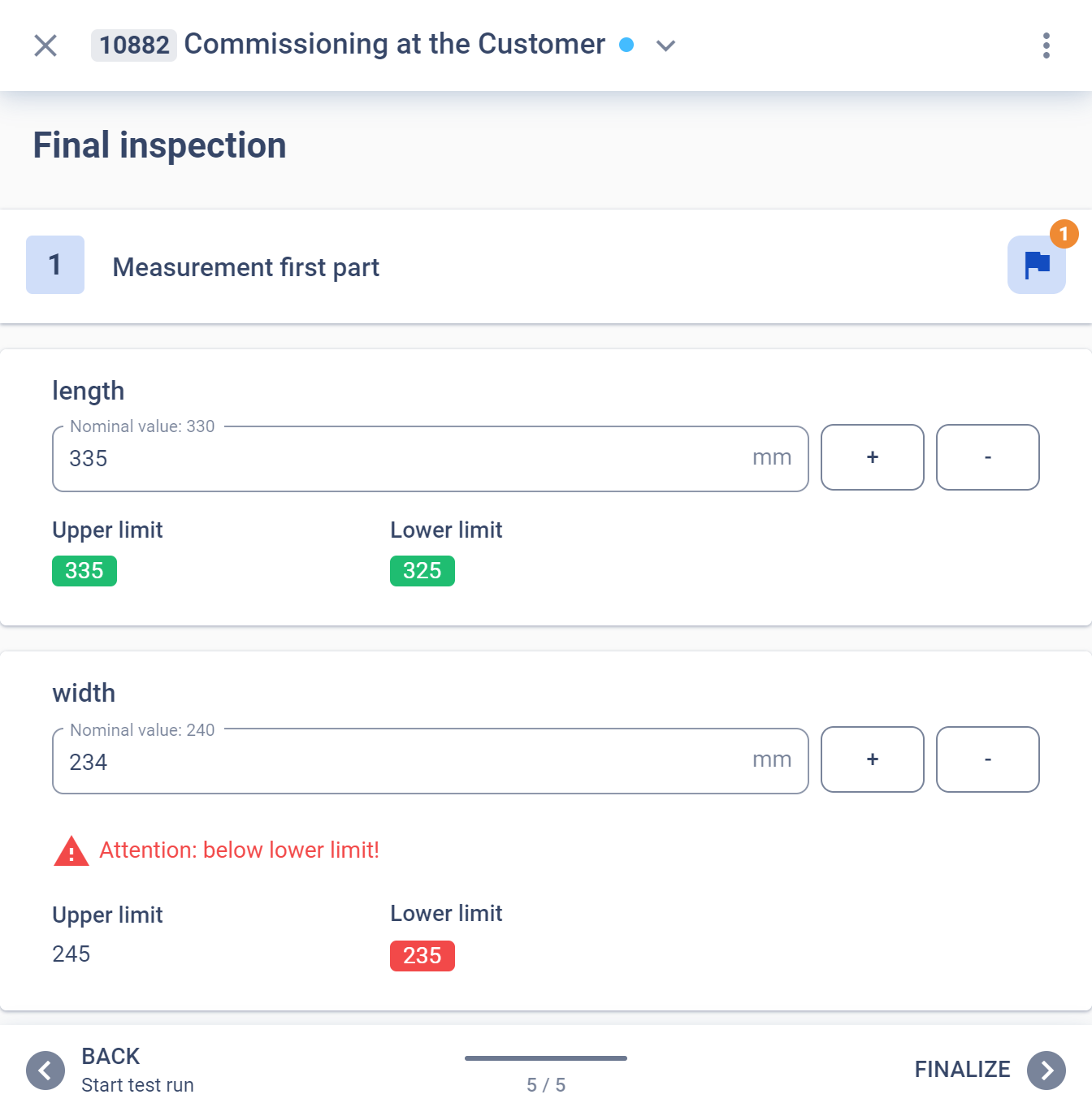

Quality testing: The quality of the machine is checked to ensure that it meets requirements and produces the desired quality output.

Training: Operators and maintenance personnel are trained in the proper use and maintenance of the machine.

Documentation: All relevant documentation, such as operating manuals and maintenance records, is provided and reviewed to ensure that the machine is properly understood and maintained.

Overall, commissioning a machine involves all the steps necessary to ensure that a machine is properly installed, tested, and ready for operation.