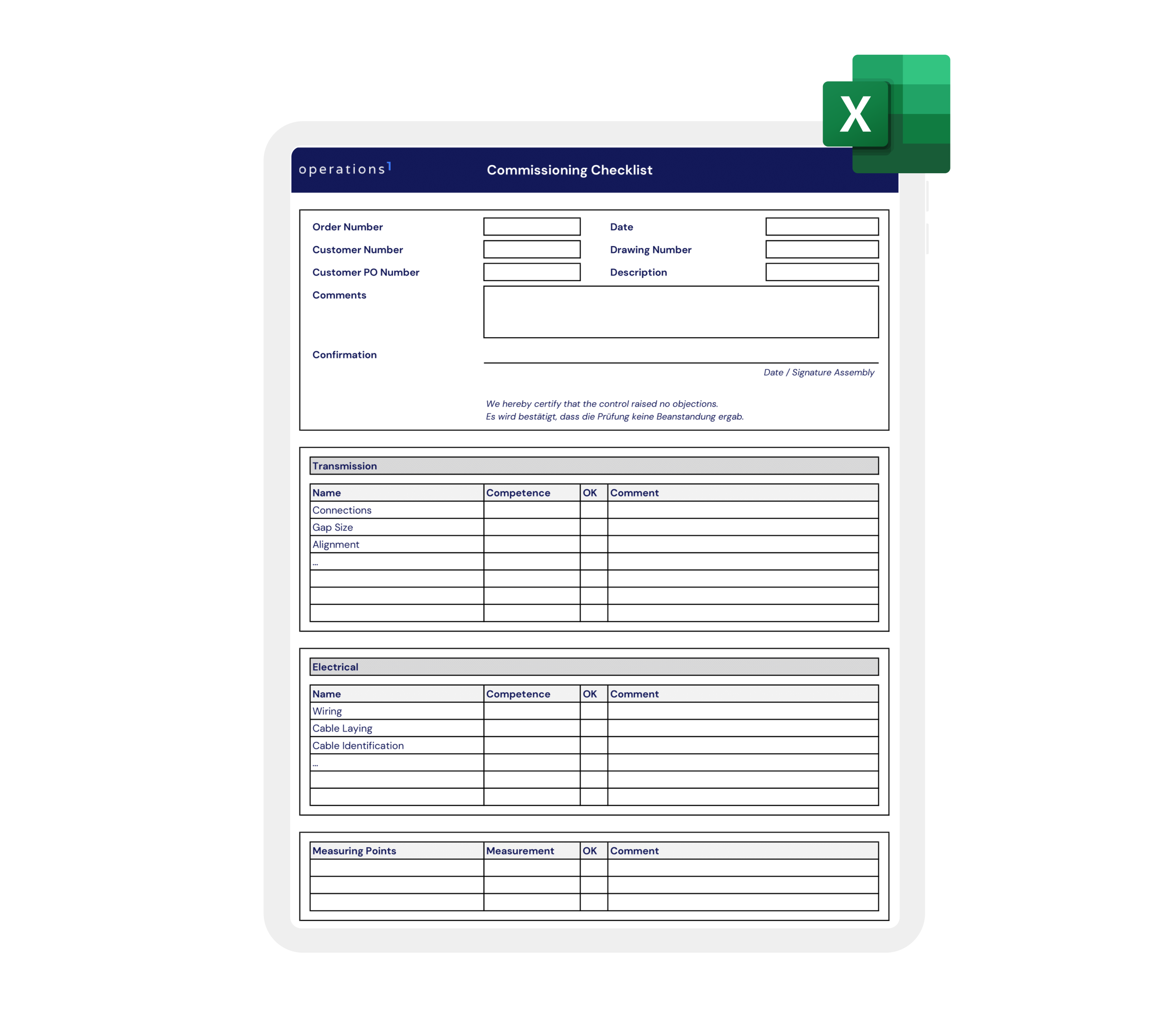

Paper-based commissioning typically has three key challenges: a high level of document handling and information provision, a delay in commissioning due to non-value-added activities, and low traceability and transparency.

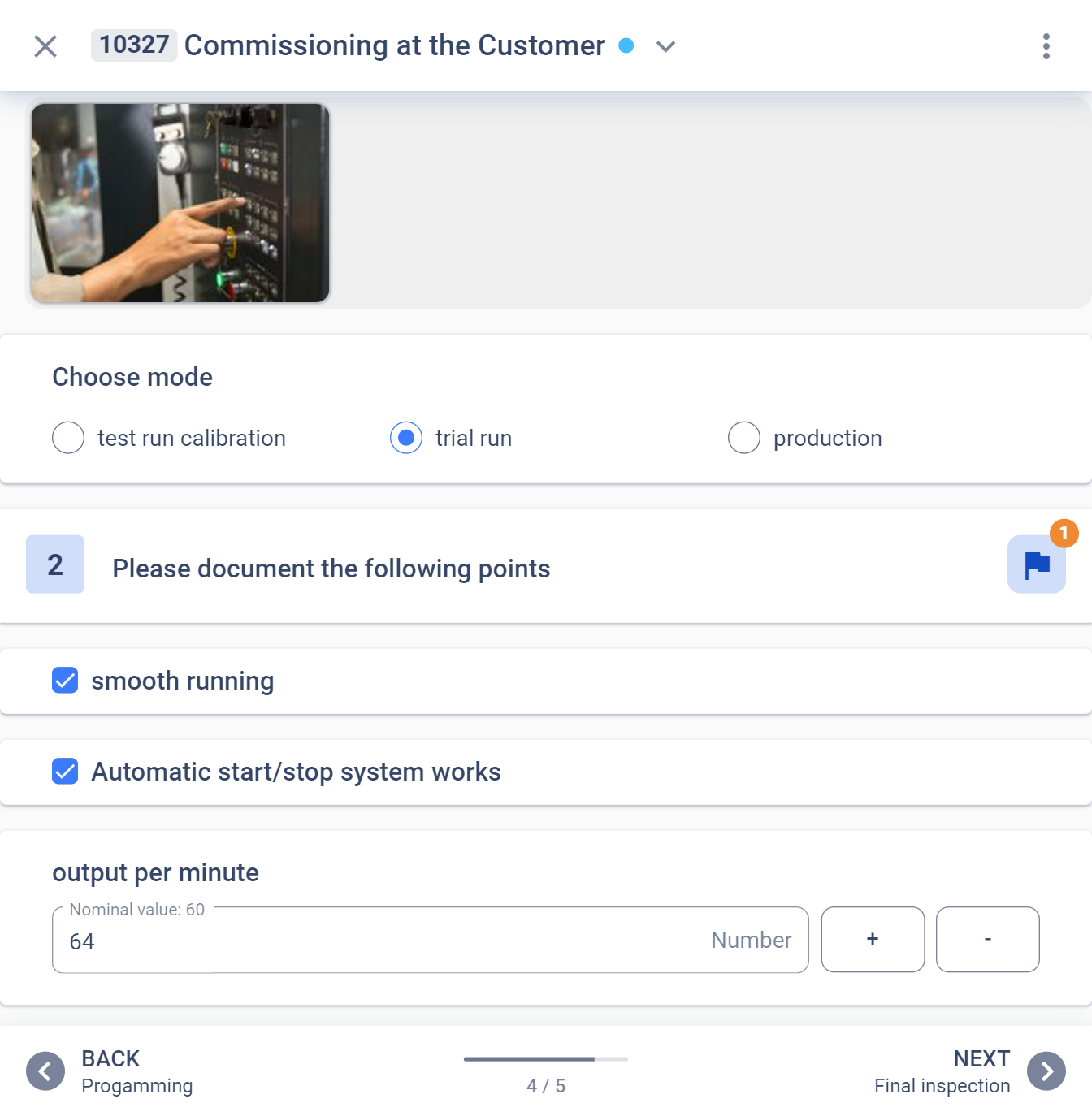

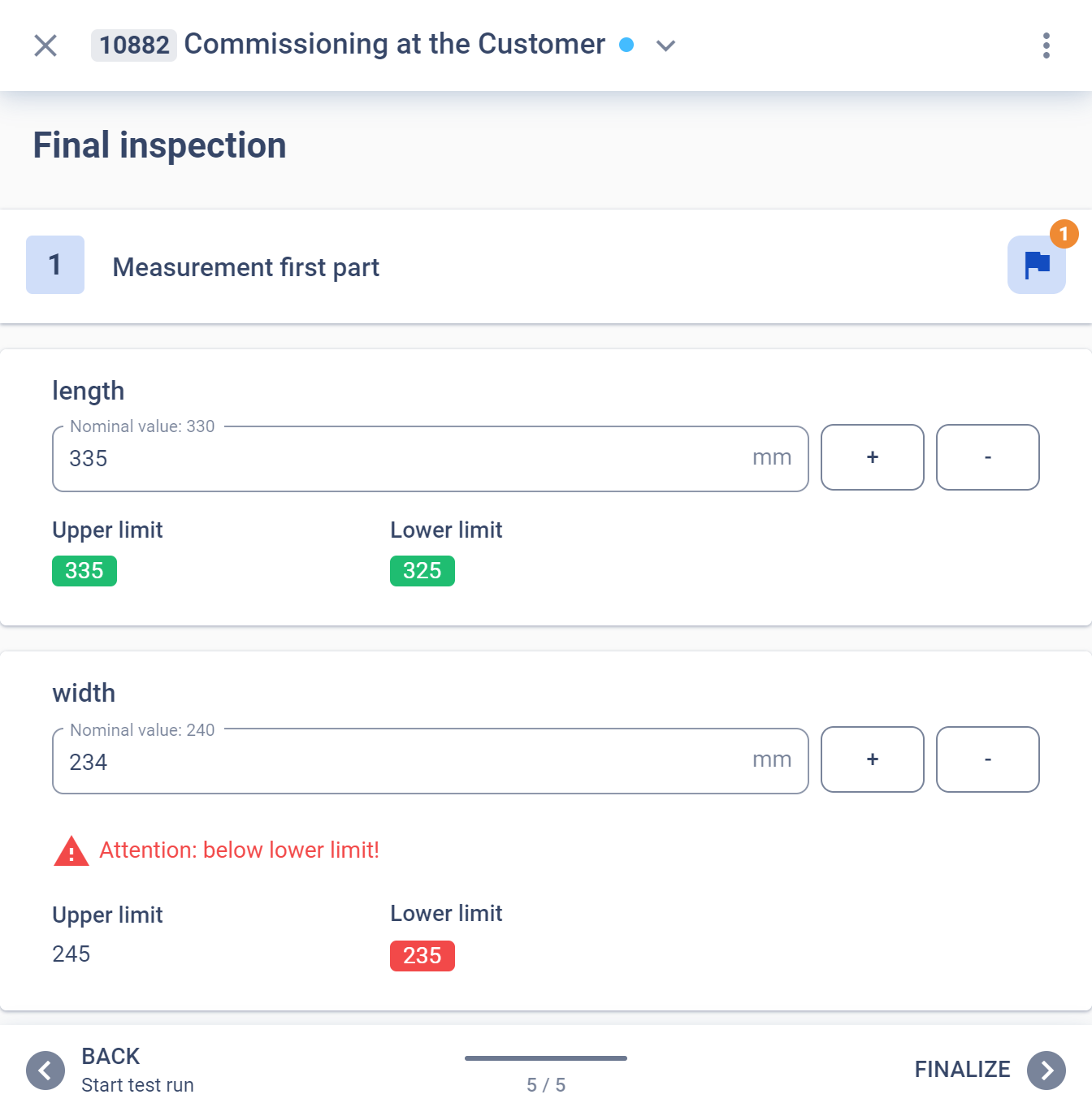

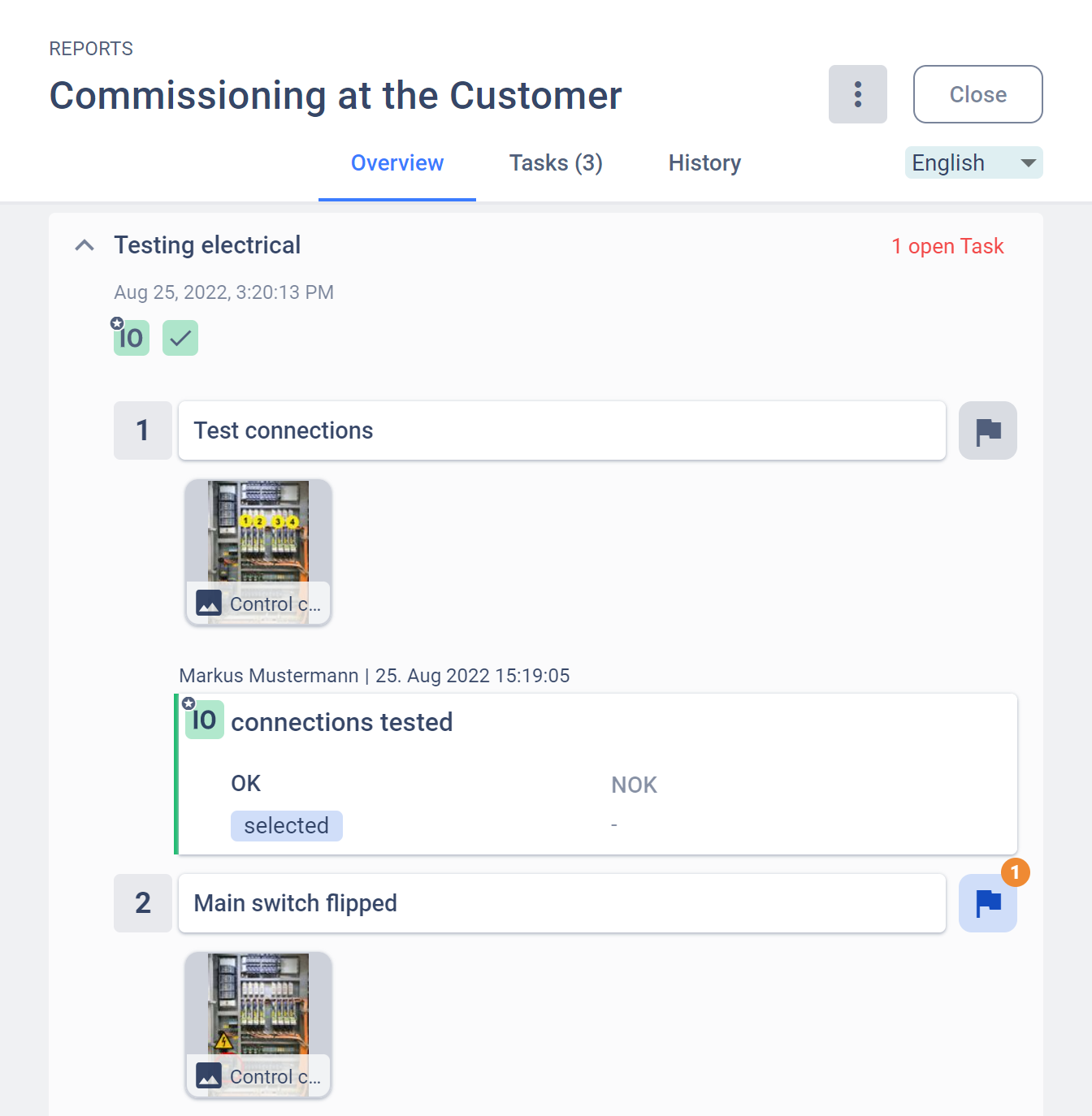

Industry leaders rely on Operations1 in commissioning

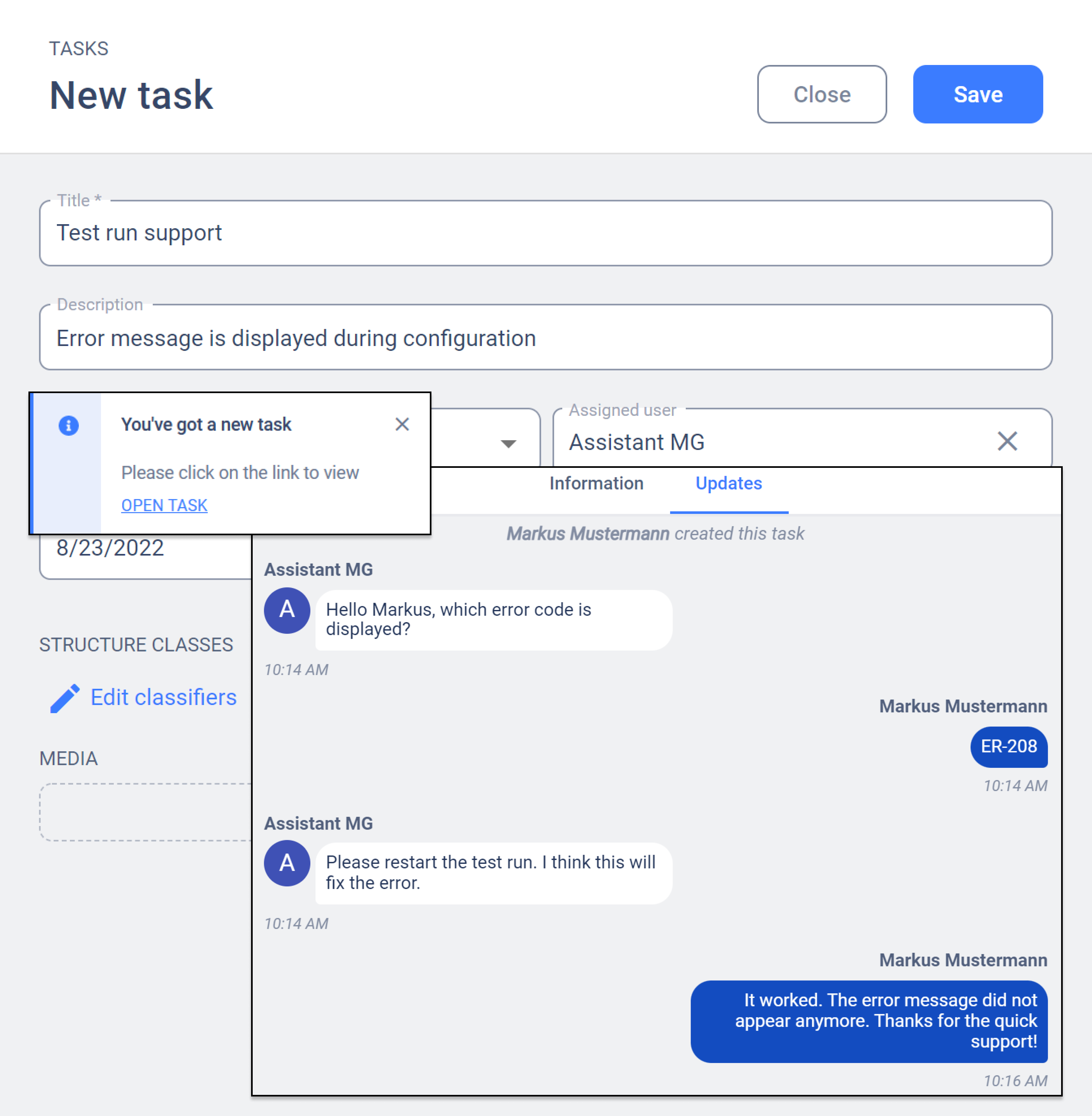

Also carry out your commissioning intelligently, provide maintenance knowledge paperlessly and in real time, and set global process standards. Connect Operations1 with your inventory systems such as ERP and MES, if required.