What is a plant walkthrough?

A plant walkthrough refers to a planned tour or inspection of a production facility or workplace. It involves a systematic review of facilities, work processes, safety standards, environmental conditions, and other relevant aspects in order to assess the overall condition and operational efficiency of the plant.

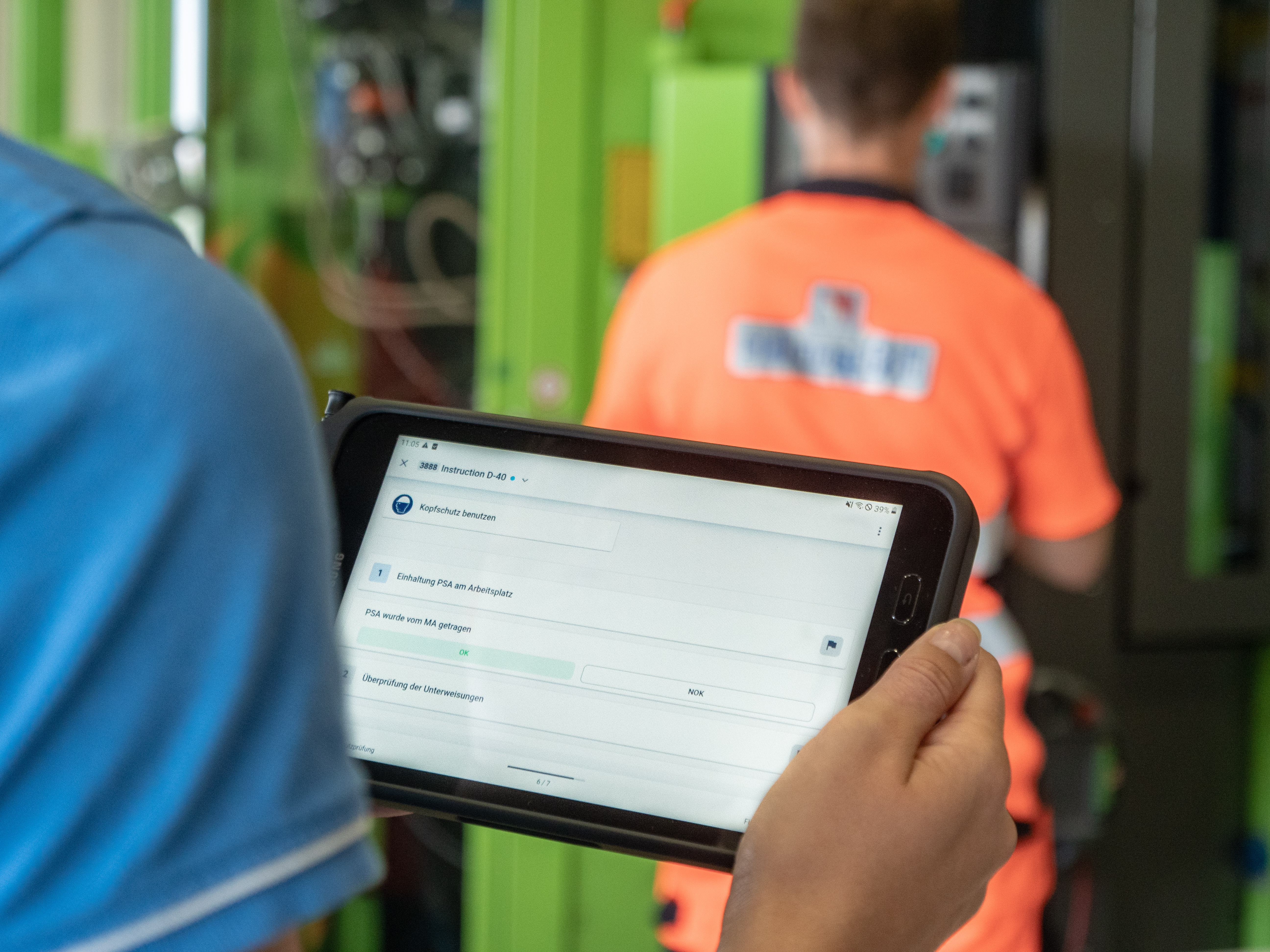

Plant walkthroughs are typically conducted by managers, safety officers, quality managers, or other relevant stakeholders. The findings are documented and serve as a basis for actions aimed at improving and optimizing operations.

What is done during a plant walkthrough?

During a plant walkthrough, various activities are carried out to assess the overall condition and efficiency of operations. The specific steps and actions may vary depending on the type of facility, the defined objectives, and regulatory or operational requirements. Typical activities during a plant walkthrough include:

Walkthrough of the facility premises: The plant walkthrough usually starts with a general inspection of the site or workplace. This includes reviewing outdoor areas, parking spaces, access routes, and other relevant surroundings.

Inspection of facilities and areas: Production areas, offices, warehouses, and other facilities are reviewed. The condition of buildings, cleanliness, organization, and overall safety are assessed.

Review of machines and equipment: Machines, equipment, and production lines are inspected. Their condition, maintenance status, safety features, and compliance with operating requirements are evaluated.

Inspection of workstations: Workstations and work areas are assessed with regard to ergonomics, order, cleanliness, and other factors that influence working conditions.

Review of safety standards: Compliance with safety standards and guidelines is checked. This includes fire protection measures, personal protective equipment (PPE), emergency preparedness, and other safety-related aspects.

Review of quality standards: In manufacturing environments, the walkthrough often includes verification of compliance with quality standards. This may involve reviewing quality control procedures, defect prevention and correction processes, as well as inspecting samples or finished products.

Employee interviews: Employees are often interviewed during the walkthrough to gather feedback, observations, and improvement suggestions. This supports employee involvement and helps incorporate shop floor perspectives.

The scope and sequence of activities during a plant walkthrough depend on the objectives, the type of operation, and specific requirements. The results are documented and used as a basis for initiating corrective actions and continuous improvement measures.

Why is a plant walkthrough conducted?

A plant walkthrough is conducted for several key reasons:

Identification of improvement opportunities: By walking through the facility, potential weaknesses, bottlenecks, or inefficient workflows can be identified. This makes it possible to define measures to improve productivity, operational efficiency, and quality.

Verification of compliance with standards: Plant walkthroughs help ensure that defined standards, regulations, and internal guidelines are being followed. This includes safety standards, environmental requirements, legal regulations, and company-specific policies.

Identification of safety risks: Another key objective is to identify potential safety risks or hazards. This enables preventive actions and risk mitigation measures to protect employees and ensure safe operations.

Assessment of equipment and asset condition: Plant walkthroughs allow for the evaluation of the condition of equipment, machines, and assets. This includes checking for wear and tear, maintenance needs, and potential repair or servicing requirements.

Employee involvement: Plant walkthroughs provide an opportunity to involve employees and consider their knowledge, observations, and improvement suggestions. This strengthens employee engagement and cross-functional collaboration.

How often should a plant walkthrough be conducted?

The frequency of plant walkthroughs can vary depending on the company, industry, type of operation, and specific requirements. There is no universally defined standard frequency for conducting plant walkthroughs.

Some organizations carry out regular walkthroughs to continuously monitor operational conditions, ensure compliance with standards, and identify improvement opportunities. In such cases, plant walkthroughs may be conducted daily, weekly, monthly, or at other defined intervals.

It is important that the frequency of plant walkthroughs is appropriate to ensure potential issues are identified in a timely manner and improvement actions can be initiated. The exact frequency should be defined in internal policies, procedures, or within the company’s safety and quality management plans. Regardless of the chosen frequency, plant walkthroughs should be conducted regularly and systematically to monitor operations, ensure compliance, and drive continuous improvement.

Get to know the software in just 3 minutes

Discover the functions of Operations1 in an interactive product tour and get to know our platform.