What is the 6S method?

The 6S method, based on the 5S method, is a workplace improvement process and part of Lean Management. The 6S method, also referred to as "5S + Safety", assists in maintaining productivity and safety in the workplace. The six steps of the 6S method are: sort, systematize, clean, standardize, self-discipline and safety.

What are the 6 steps of the 6S method?

The six steps of the 6S method are: Seiri (sort), Seiton (set in order), Seiso (shine), Seiketsu (standardize), Shitsuke (sustain), and Safety (safety).

Seiri (Sort) Unnecessary tools and materials are identified and sorted out. This makes the workplace more organized and creates more space for needed work materials.

Seiton (Set in order) A system is introduced for arranging the required work materials. Required tools and materials are arranged so that they can be accessed quickly and easily. The frequency of use as well as the order of use of the materials is taken into account.

Seiso (Shine) The own workplace and work utensils are cleaned. The cleaning of the work equipment also serves to identify deficiencies as well as potential threads. Thus, a safe and hygienic working environment is created.

Seiketsu (Standardize) All workplaces are standardized. For example, uniform markings and labels are used for work materials. The aim is to create standards that create an optimal working environment and make it easier to change workplaces.

Shitsuke (Sustain) Compliance with the above rules is to become a habit. Likewise, the rules are to be constantly reviewed and improved in order to achieve the best possible benefits.

Safety To ensure safety in the workplace, potential sources of danger are searched for. After identifying the sources of danger, potential measures are defined and implemented to minimize the danger and increase safety.

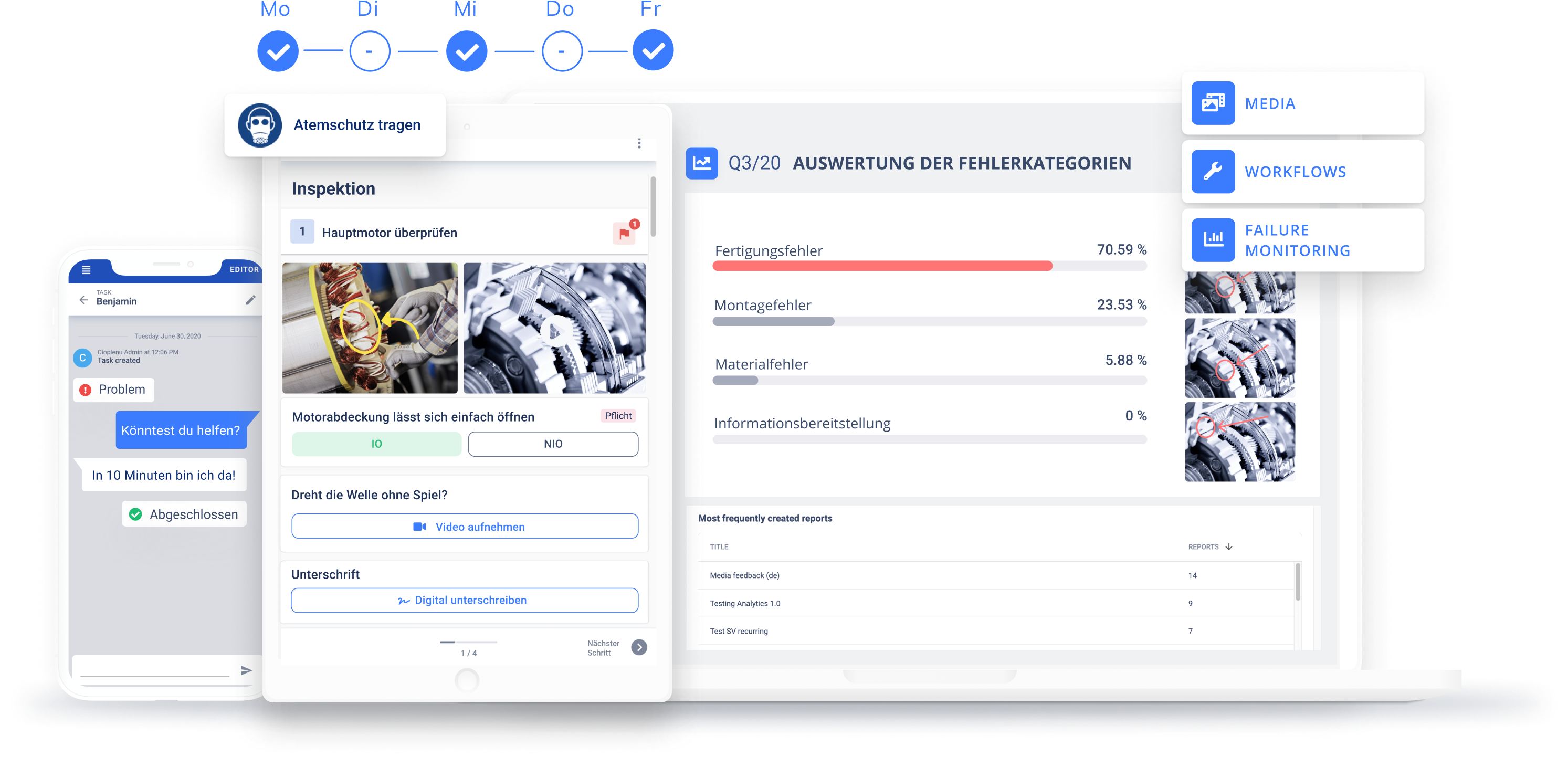

Discover 6S checklists in action

Discover the functions of Operations1 in an interactive product tour and get to know our platform.

What are the advantages of the 6S method?

The 6S method is used to create a clean, organized and safe work environment that can increase employee efficiency and productivity. In the process, waste, such as wasted work time searching for appropriate work materials, is reduced. By increasing safety in the work area, workplace accidents are reduced, resulting in less staff absenteeism.

What are the disadvantages of the 6S method?

Implementing the 6S method involves a certain investment of time and money. It requires time and investment to implement the changes and ensure that the steps are implemented successfully.

Get to know the software in just 3 minutes

Discover the functions of Operations1 in an interactive product tour and get to know our platform.