Eliminate cost drivers in processes: Reduce errors. Establish standards. Higher productivity. Paperless production. Better training. More automation.

Manufacturing companies in the DACH region are facing increasing cost pressure, a shortage of skilled workers and international competition from state-subsidized markets such as the USA and China:

Steadily rising wage costs

Higher energy and raw material prices

Threat to the production location

Identify hidden costs in processes

Complicated process knowledge and long training times limit the flexibility of your employees

Machine breakdowns, rejects, rework and complaints cost you reputation, time and money

Dependence on external service providers and their expertise leads to additional costs

Utilize productivity potential and reduce costs

Identify the potential for improvement in your production processes, reduce unnecessary costs, strengthen your competitiveness and secure your location.

Manage process knowledge centrally

Secure your employees' knowledge digitally and centrally in one software. Create easy-to-understand instructions and checklists and also eliminate unnecessary search, change or provision efforts that cost you time.

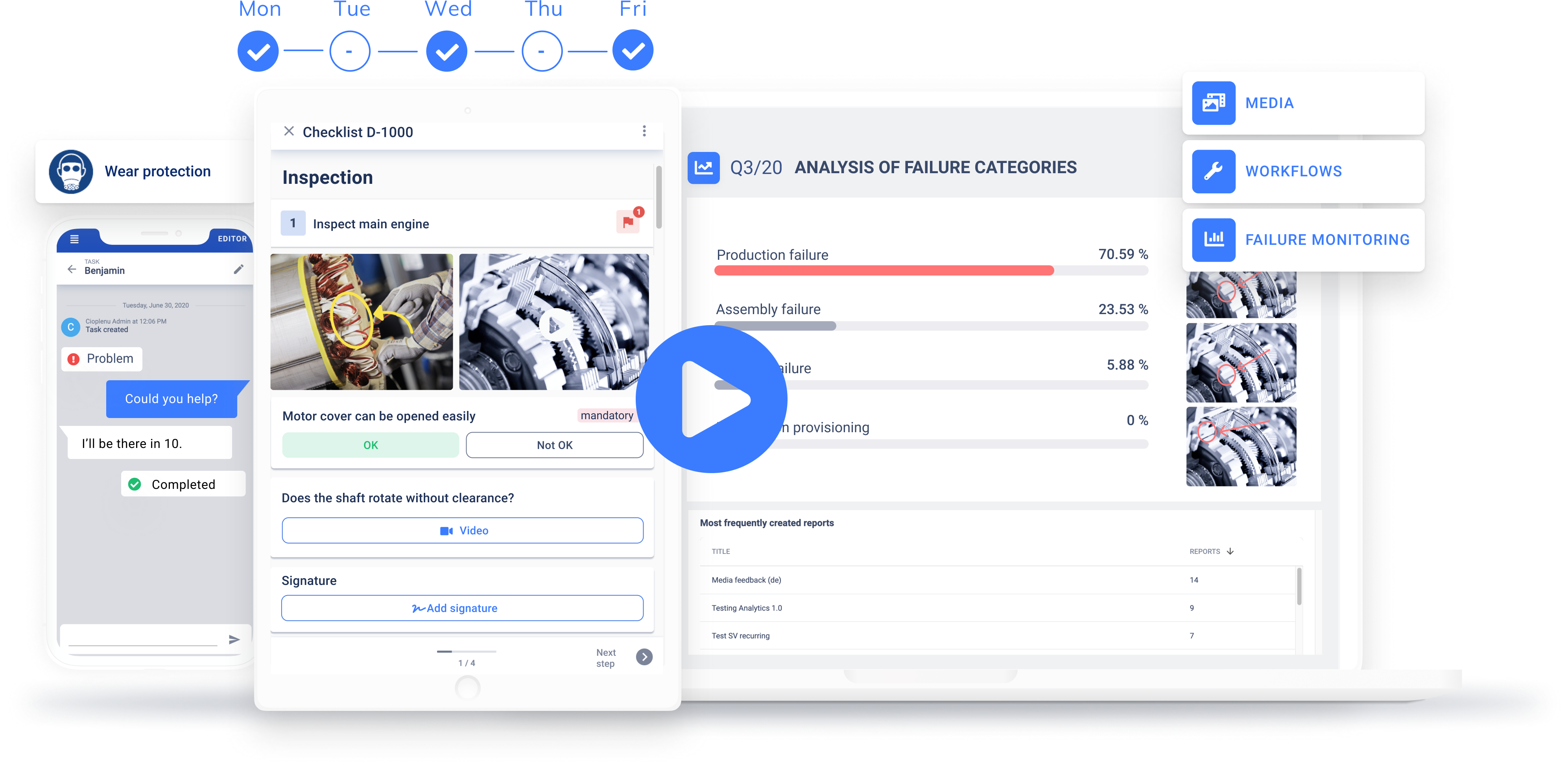

Reliable process execution

Show your employees exactly what they have to do using step-by-step instructions supported by images and videos. This will give them more confidence and contribute to productivity and error reduction.

Empower your employees

With comprehensible work instructions, your employees can learn new knowledge, take on additional tasks and thus be deployed more flexibly. This makes you independent and allows you to avoid external service costs.

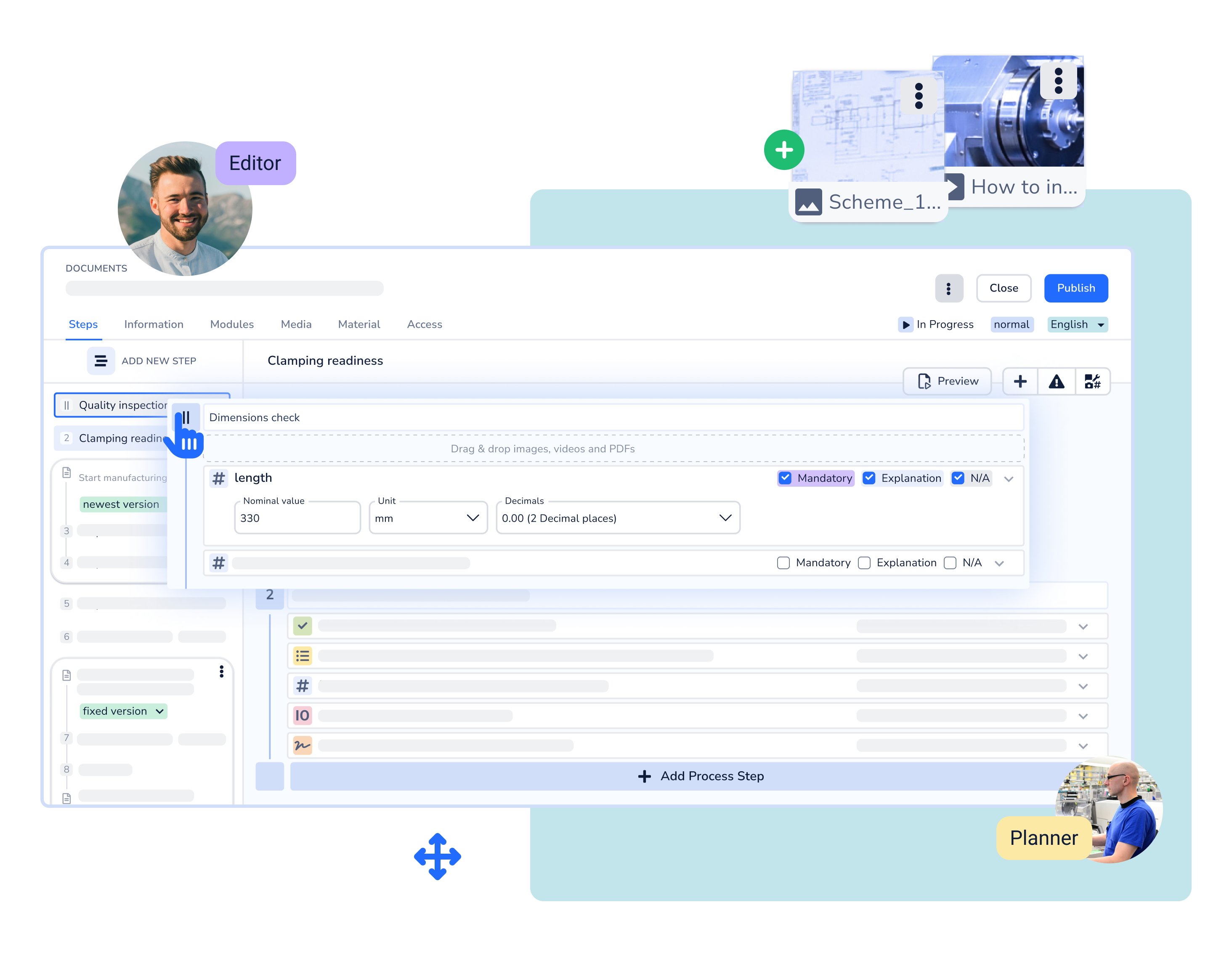

Quickly create smart documents

Create your digital work instructions or checklists with just a few clicks using the user-friendly drag & drop editor.

Wide selection of interactions for work steps

Easy integration of media such as images and videos

Efficient and intuitive no-code creation

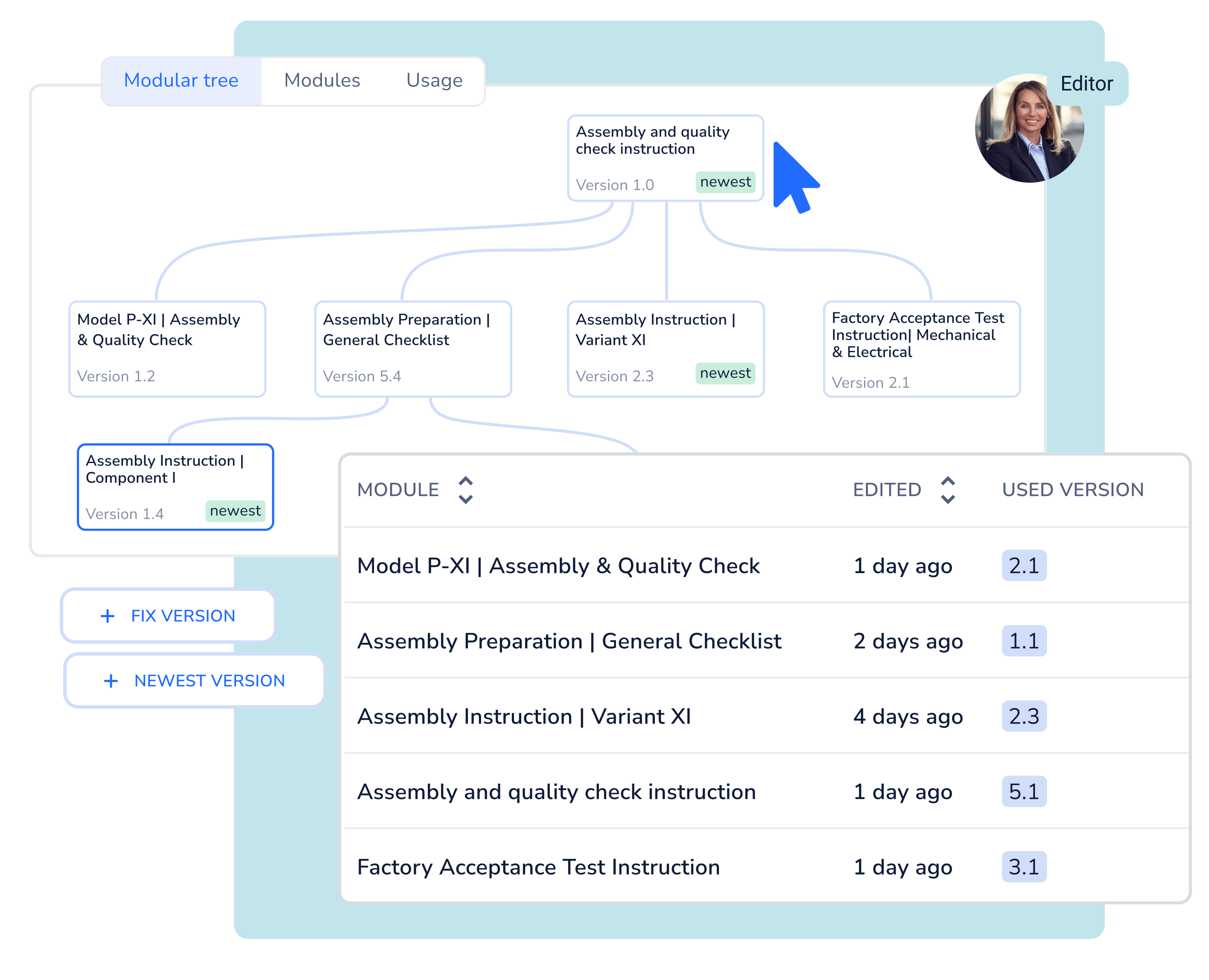

Managing a high variety of variants with reduced effort

Say goodbye to maximum lists: use a document as a module for mapping identical content in multiple documents.

Identical content maintained and updated centrally

Reduced effort and time savings

Less interpretation work for your employees

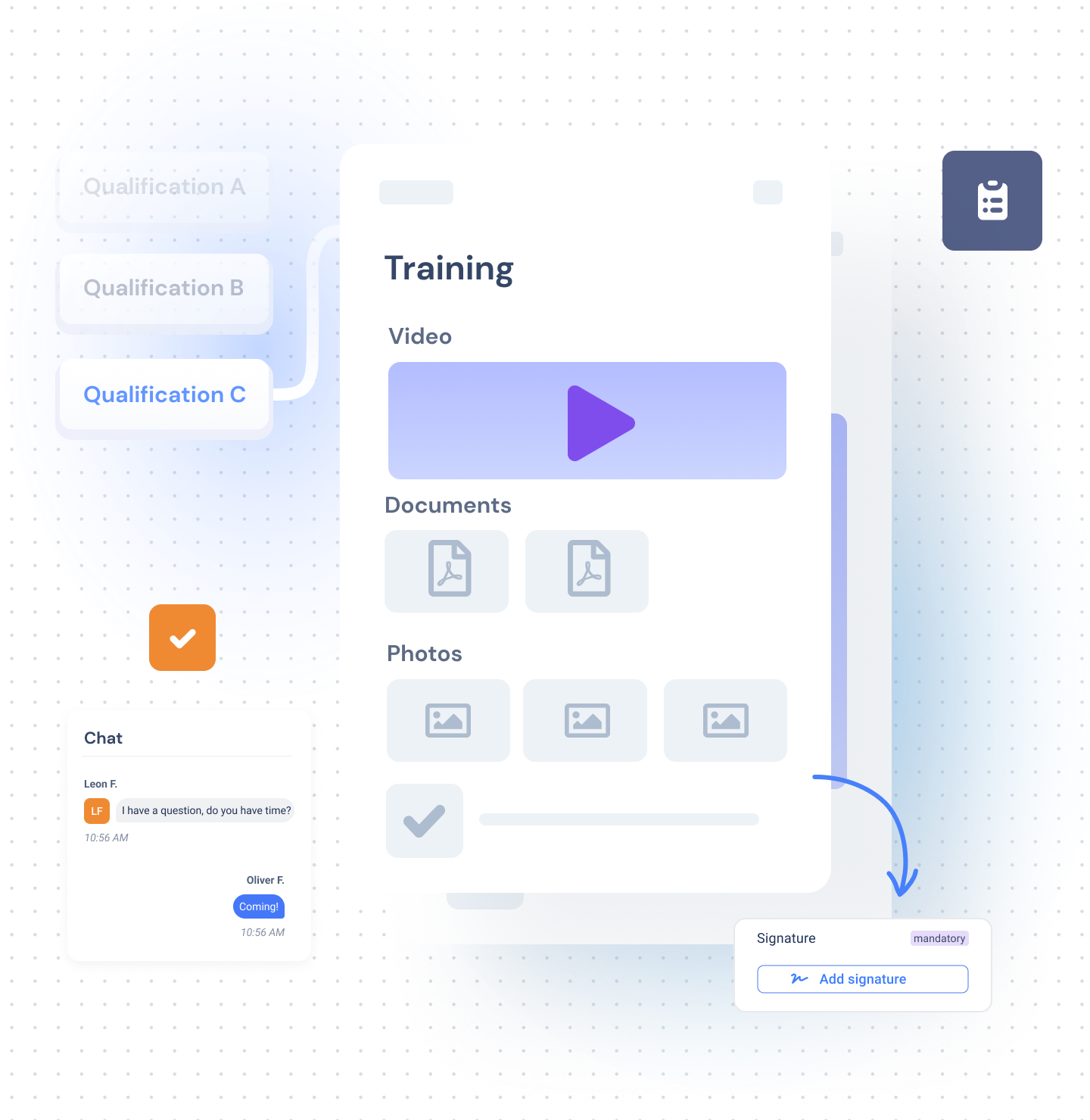

Train employees faster and make them more flexible

Present complex information to your employees in an understandable way using images, video and multilingualism. This enables both new and experienced employees to carry out new tasks quickly and independently.

Up to -67% training time for new employees

Empowering employees for further tasks

Fast productivity achievement

Operations1 contributes to an improvement in costs and thus also to our competitiveness

Maintenance Leader, Hirschvogel Holding

Costs for external service providers saved

The Hirschvogel Automotive Group not only avoids costs by reducing machine downtimes with digital checklists:

Insourcing maintenance by making employees more flexible

Savings of € 250,000 per site

Through Operations1 we save over € 180,000 per year.

Head of Production and Test Bench, Soudronic

Increased quality and cost savings

By digitizing employee-led processes, Soudronic can increase productivity and quality standards while saving costs.

Error reduction through greater process reliability

Time savings: -95% effort for documentation

Watch our demo video

Get to know our software in just 7 minutes.

Fill out the form and get access to the video.