International production relocation: fast & standardised

Relocate production lines efficiently, error-free and globally scalable - with digital, standardised work instructions.

-67% training time for new employees

-66% time expenditure for production relocation

Consistent & location-independent product quality

Typical challenges when relocating production

Neither secure nor centrally available process knowledge

Knowledge only in the heads of specialised personnel

Process knowledge is only available locally for individual plants

Lack of global transparency & standards

No global overview of processes and activities

No standardised instructions or process standards

Hoher Aufwand bei Anlernung & Transfer

Lange Anlaufphasen bei neuen Linien & Standorten

Sprachbarrieren & ineffiziente Schulungsmethoden

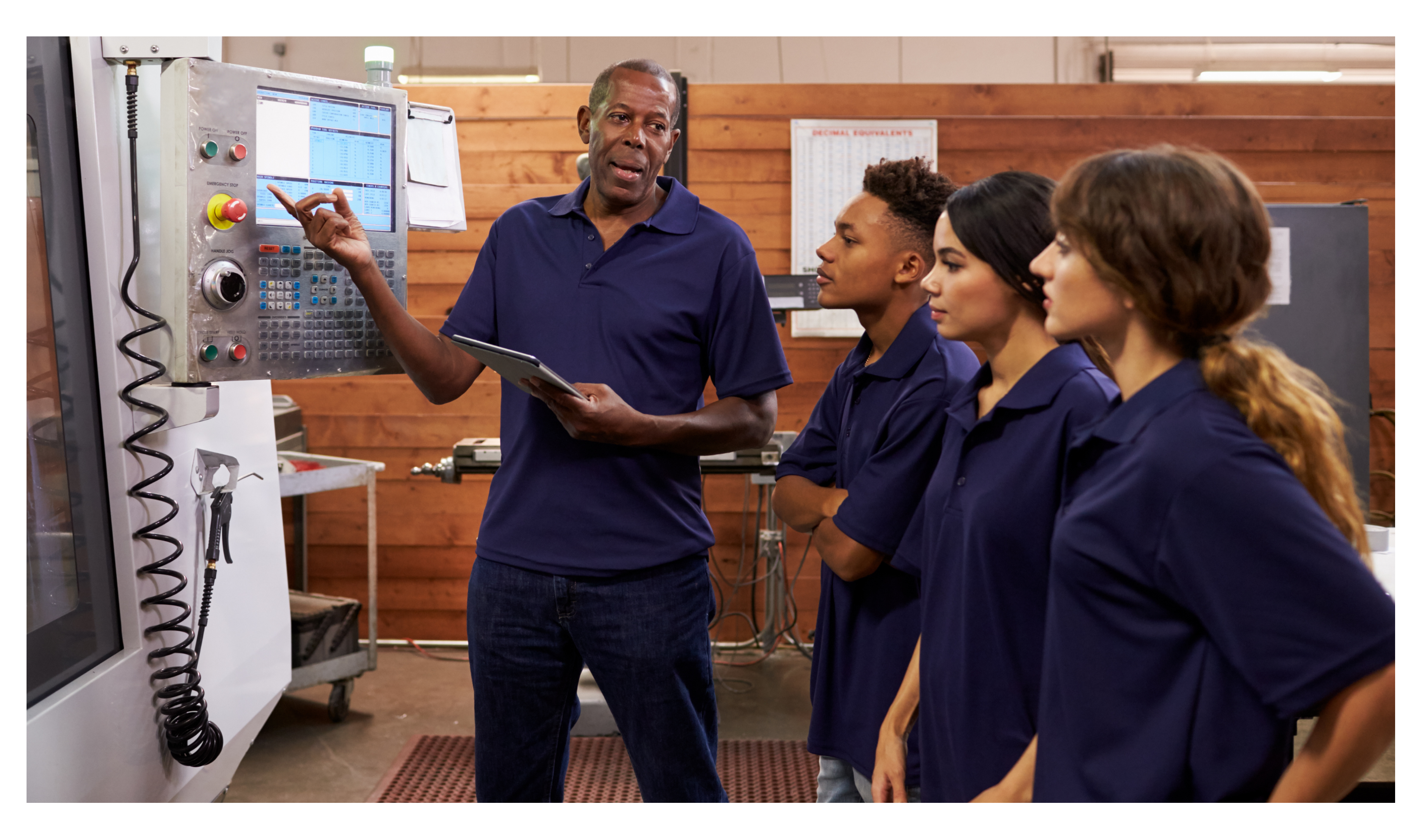

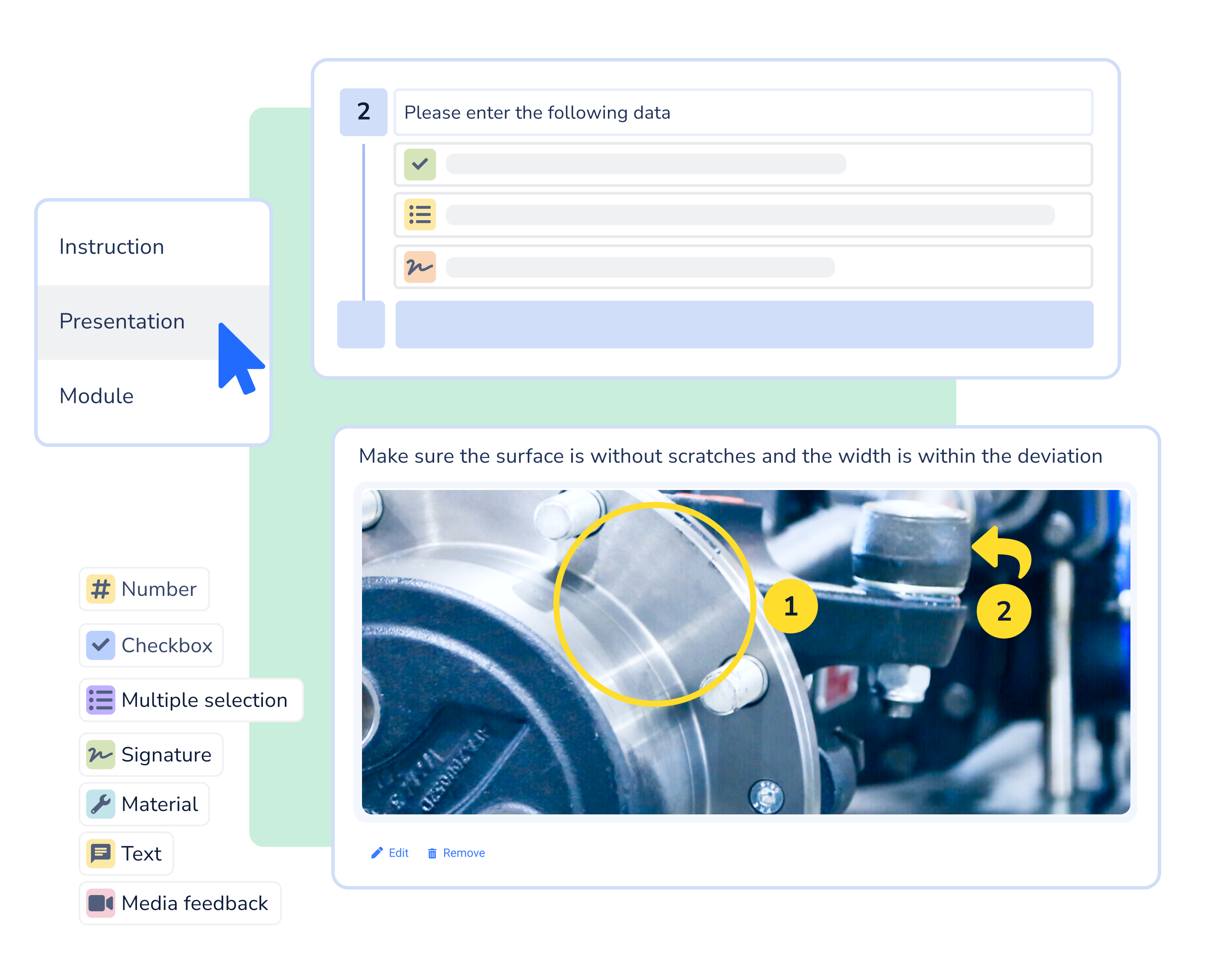

Making production expertise available globally

Document knowledge digitally once and roll it out worldwide

Multilingual provision across country and language borders

Use of multimedia content such as videos and images for clear understanding

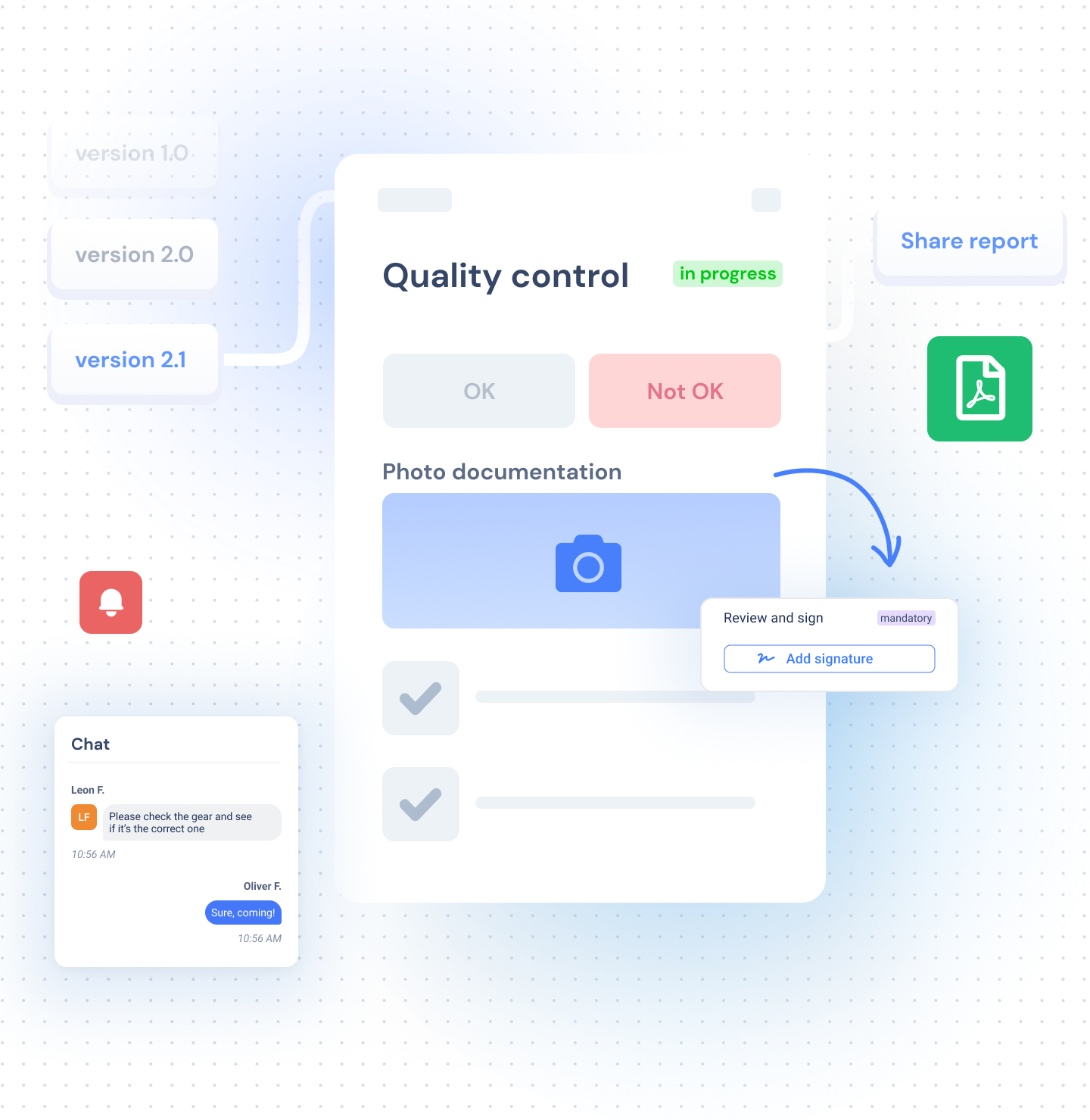

Accelerate relocation & ensure quality

Up to -66 % time expenditure for relocation of product lines

Standardised processes ensure consistent quality at every location

Automatic documentation ensures transparency for the headquarters

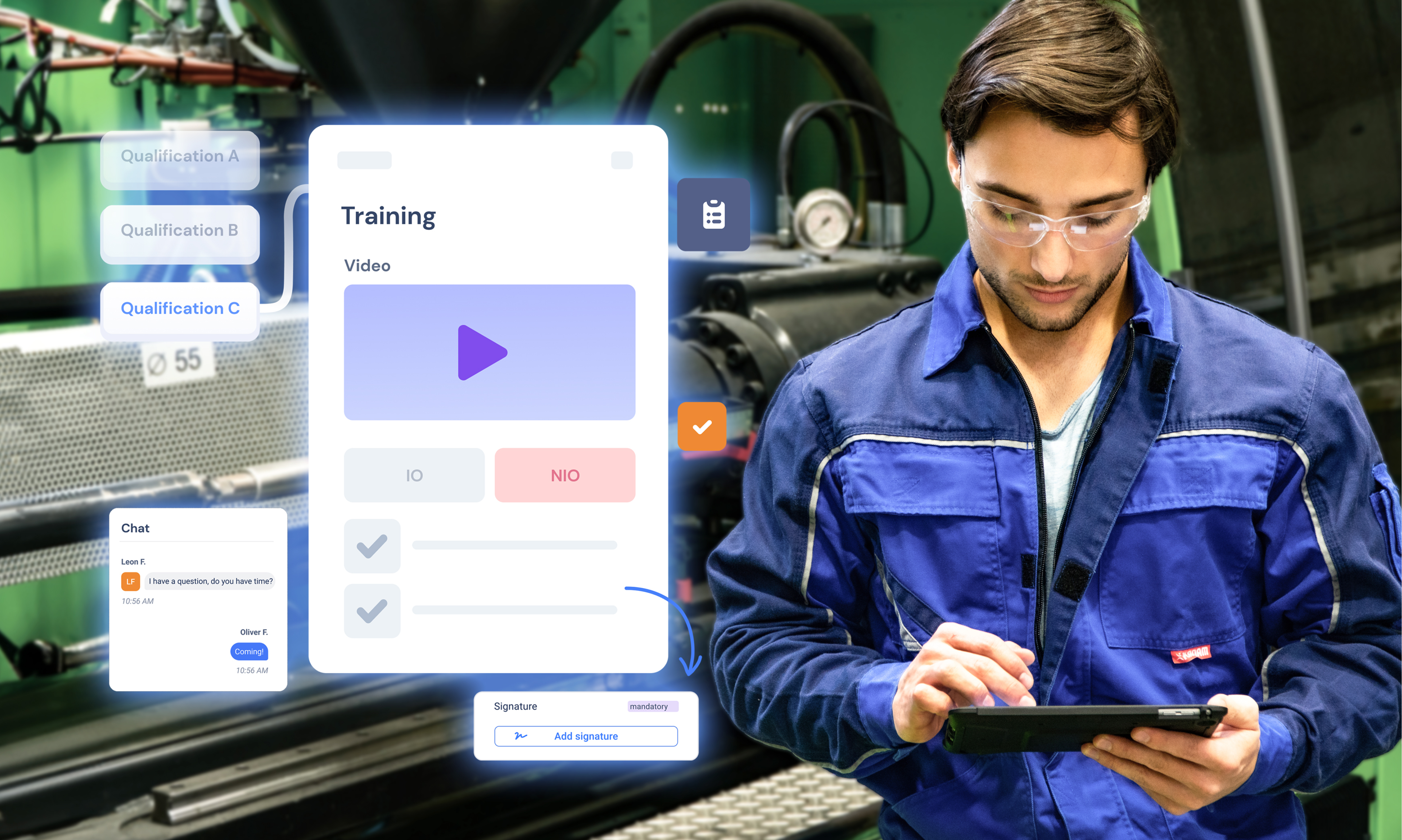

Faster training of employees worldwide

Reduction of training time by up to -67 %

Language-independent, visual instructions for easy familiarisation

Independence from the master-student principle thanks to digital worker guidance

Schedule a meeting

Take advantage of our team's many years of experience and get in touch with our product experts.

Free exchange on your individual use case

Best practices directly from practice

Presentation of solution approaches by Operations1