Production-related support processes. 100% digital.

With digital checklists and process instructions, you can simplify any support process in the Operations1 software through an intuitive interface for your employees, automatic report generation and comprehensive traceability of findings. This way, you know about the process progress at any time, can solve incidents collaboratively and use results to improve your support processes.

- 100% Usability for your employees

- -95% effort for documentation

- +21% higher productivity

Why software for support processes?

The amount of documentation required for process sheets and checklists during production is often so high that the creation, provision and evaluation of these documents requires several full-time positions. At the same time, there is little transparency to systematically evaluate activities, findings and incidents. The Operations1 software makes all employee-led processes intuitively feasible and systematically evaluable. Instead of distributed, poorly standardized MS Office documents, all plant tours, audits, cleaning procedures, instructions, shift handovers and many more can be performed and documented directly in a scalable software solution.

Central functionalities

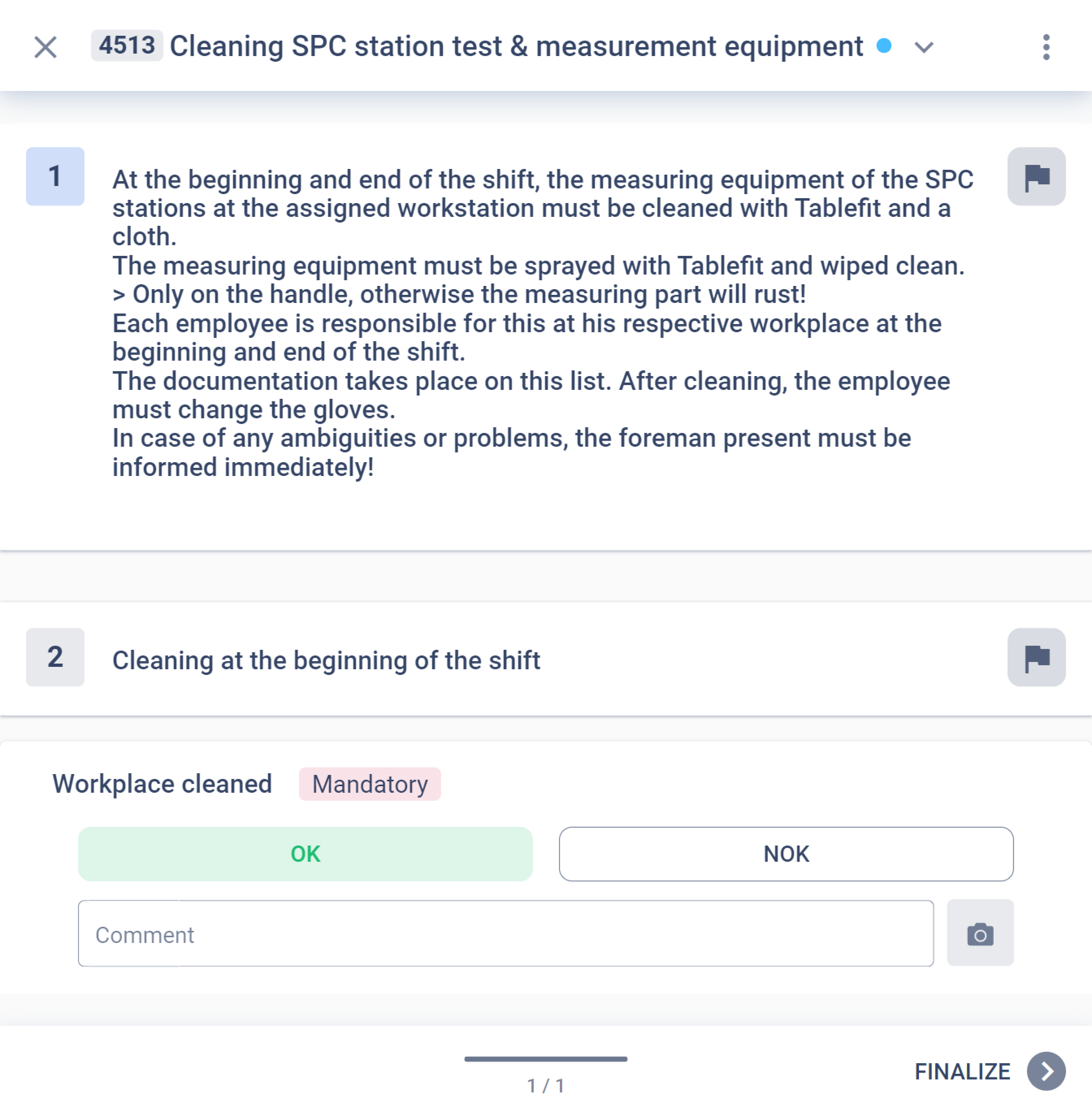

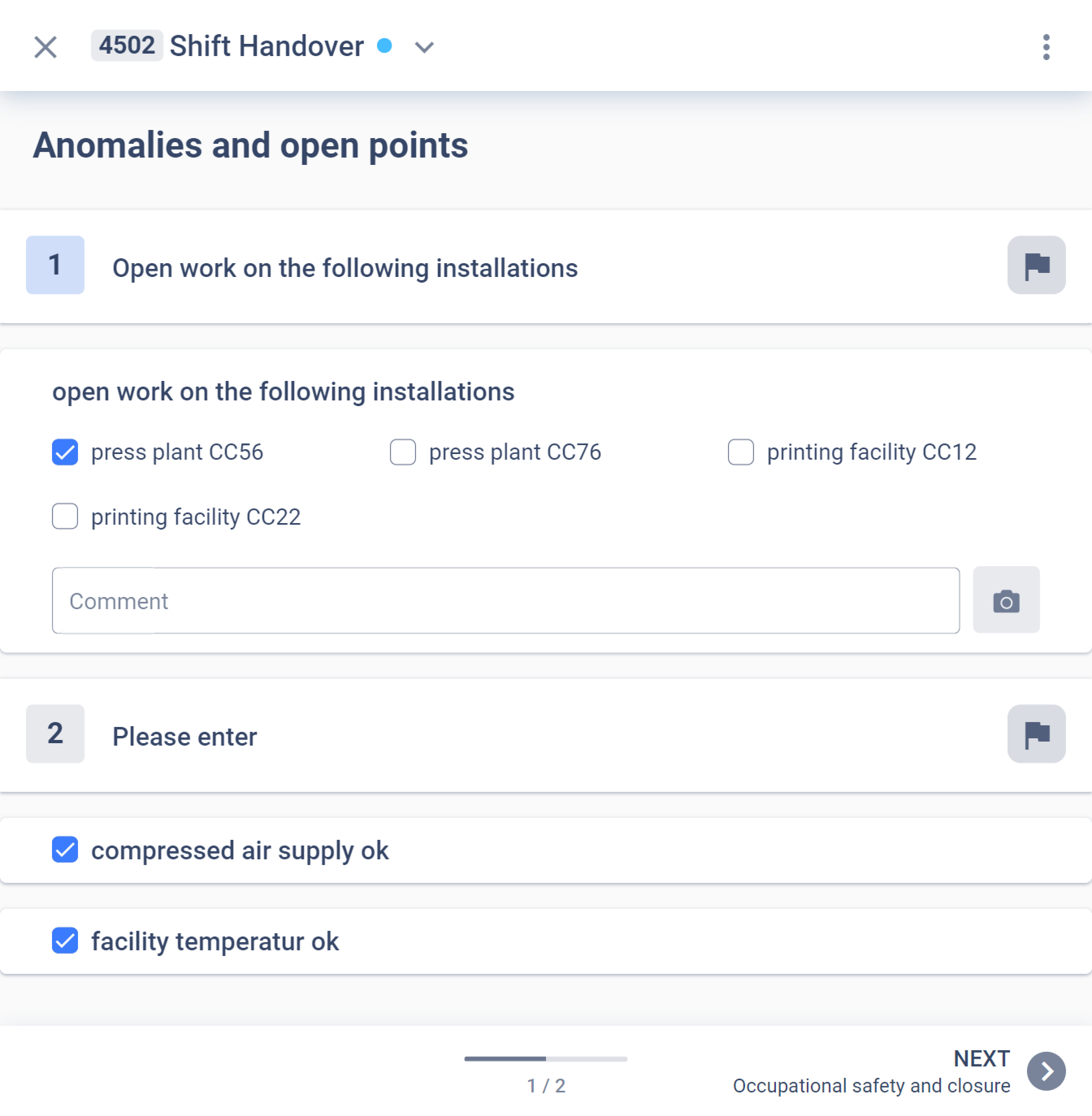

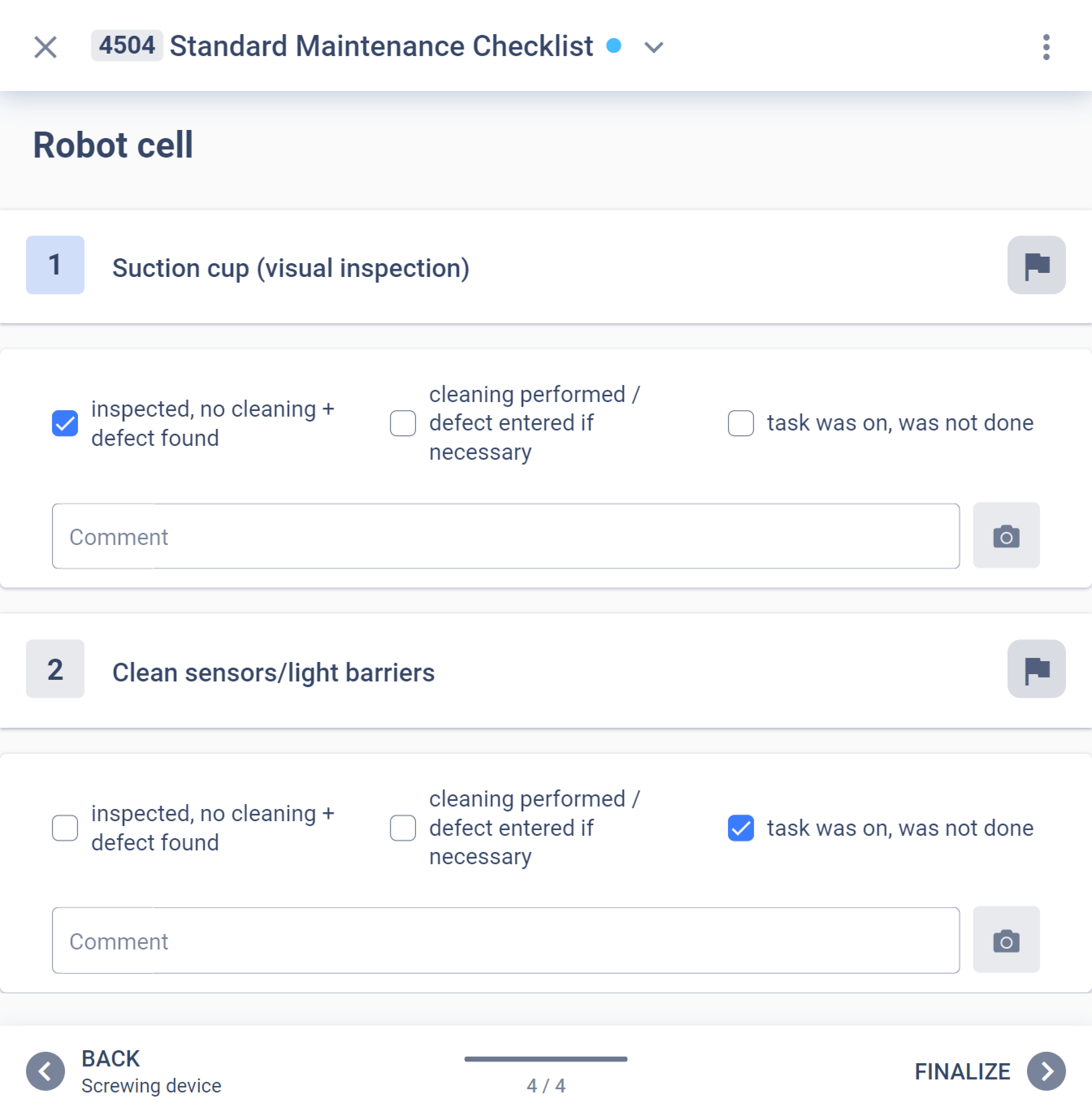

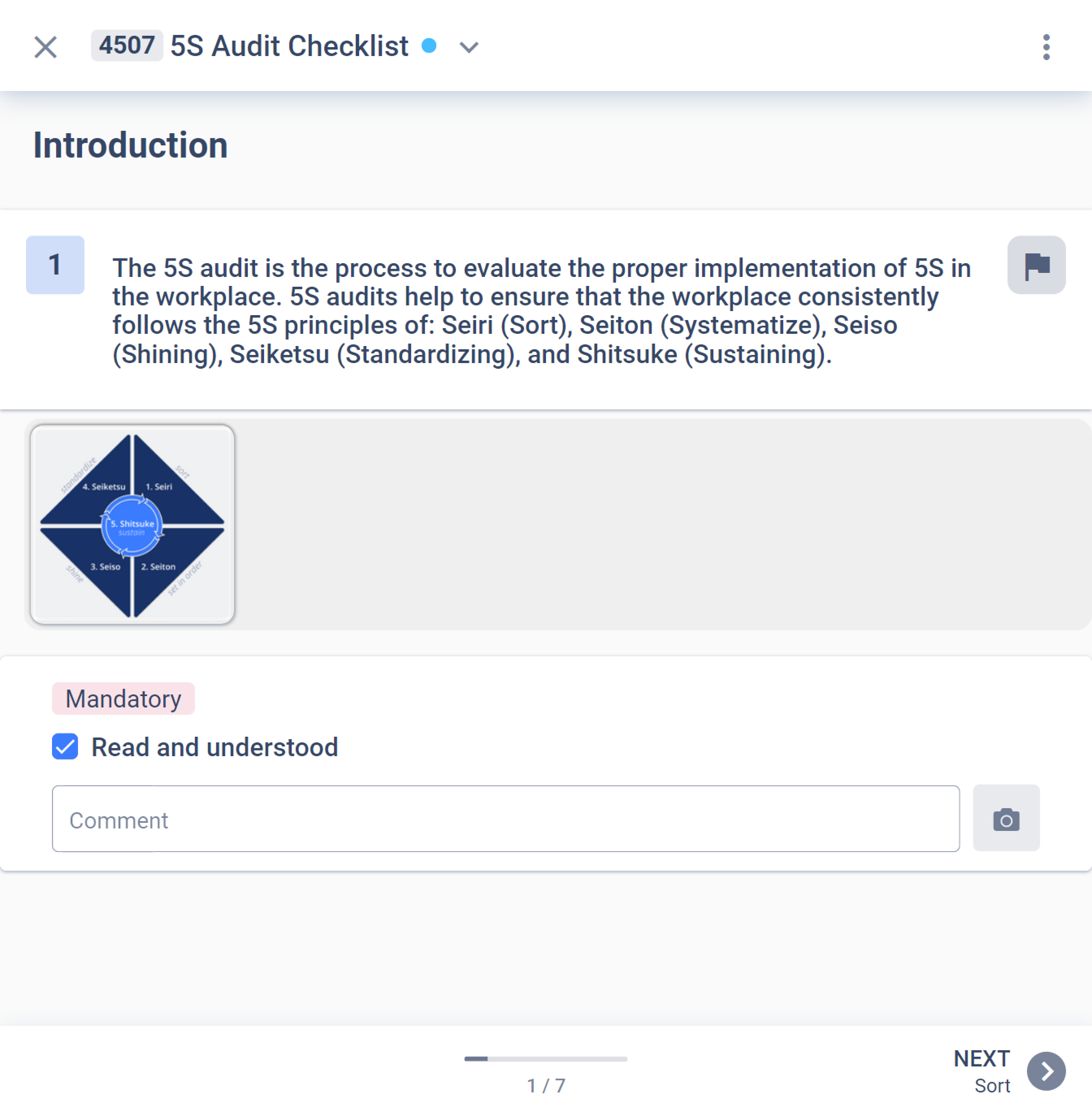

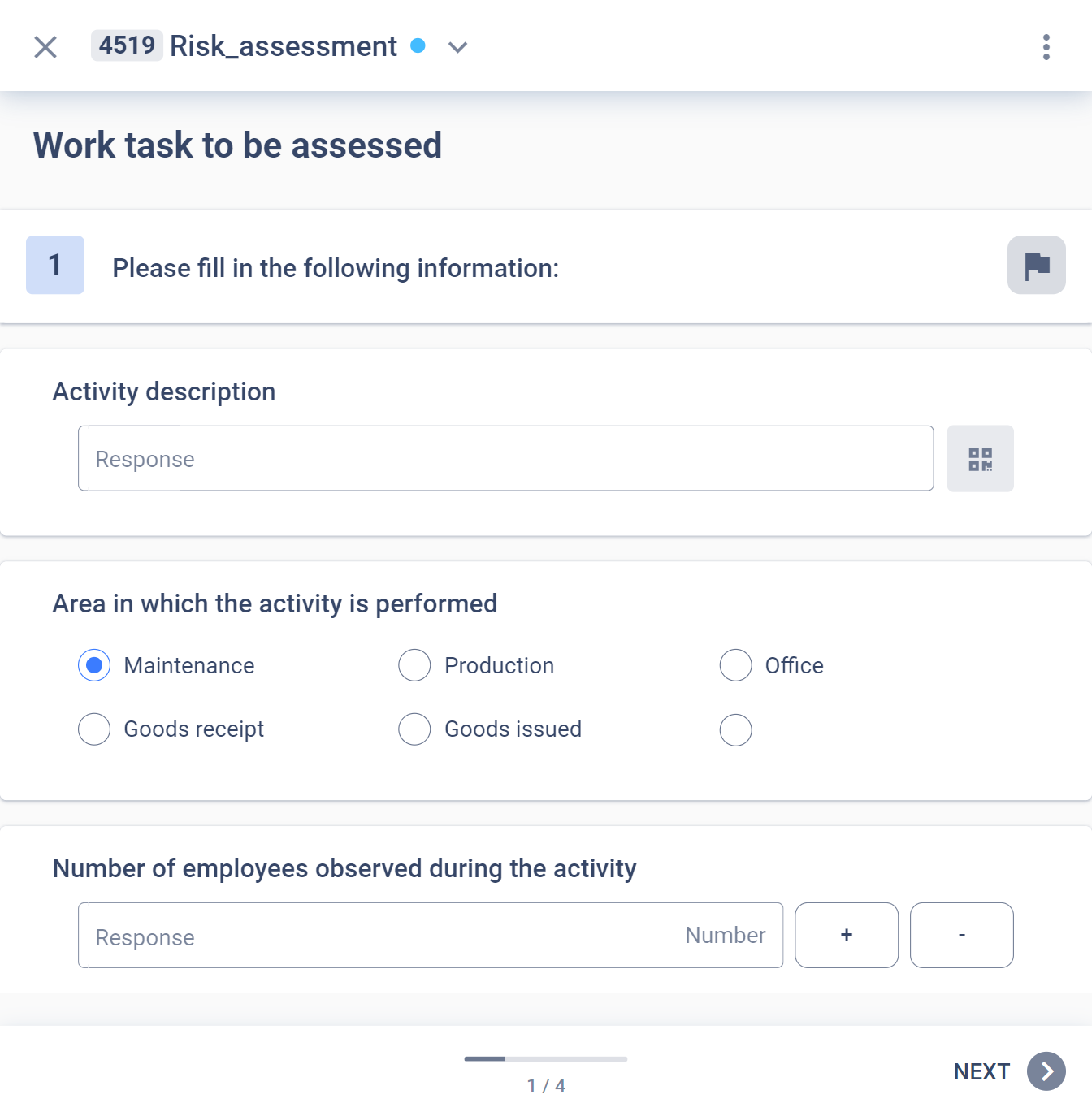

With Operations1, you eliminate any paper in your production-related support processes like 6S. All checklists and process instructions can be created simply by drag & drop and released digitally. Your operational staff will always receive the latest version of your documents on the device of your choice thanks to the cloud approach. The document can be accessed via search function, QR code scan or through an order link. Generated data points as well as information on process progress are made evaluable in a central overview. This ensures that all processes are carried out, incidents are resolved and the collected data is used for continuous improvement.

Image and video

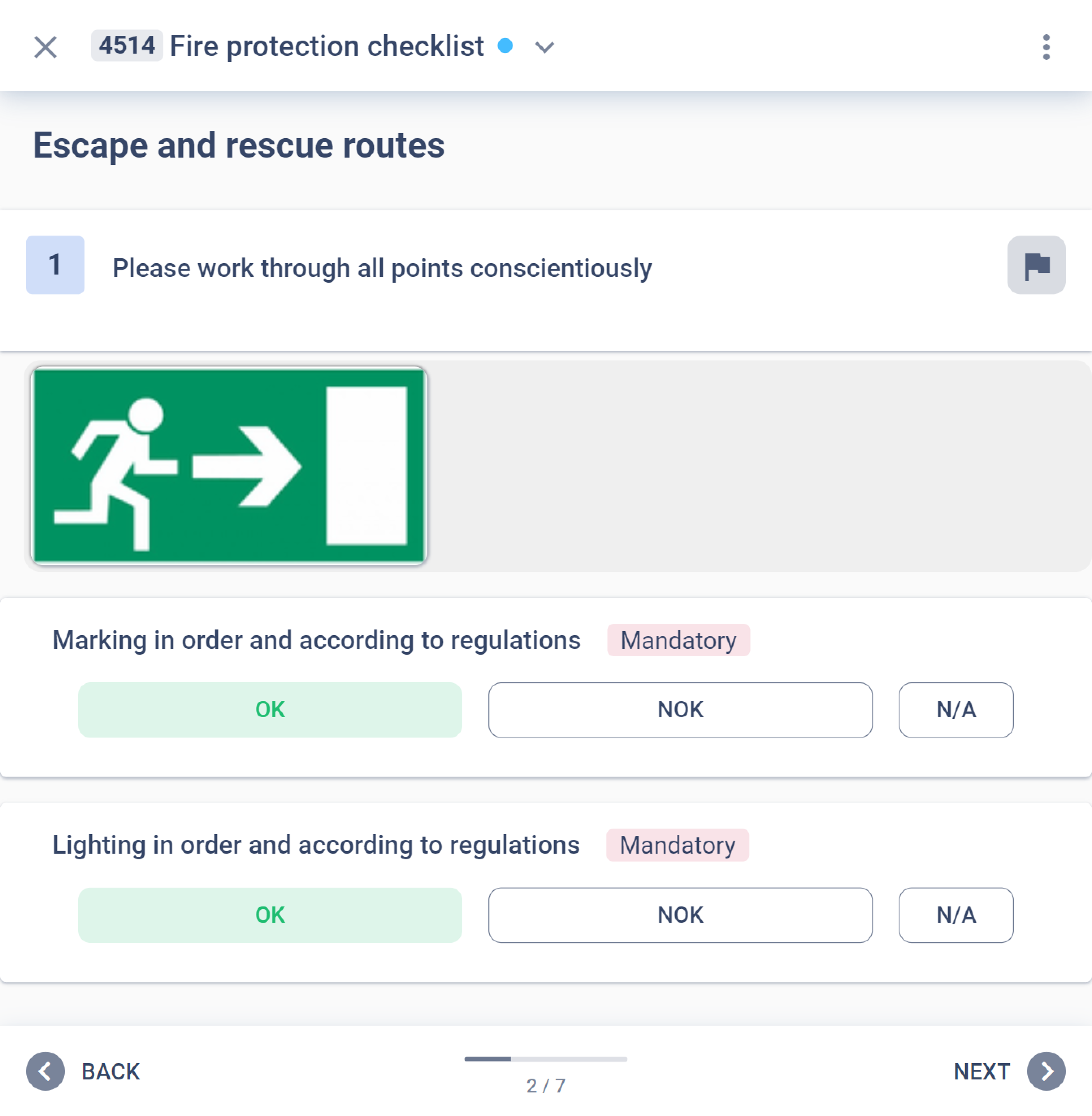

Use images and videos to make processes intuitively understandable regardless of employee qualifications and language.

Mobile

Use checklists and process instructions mobile on tablets, smartphones and laptops for any walk-throughs and audits.

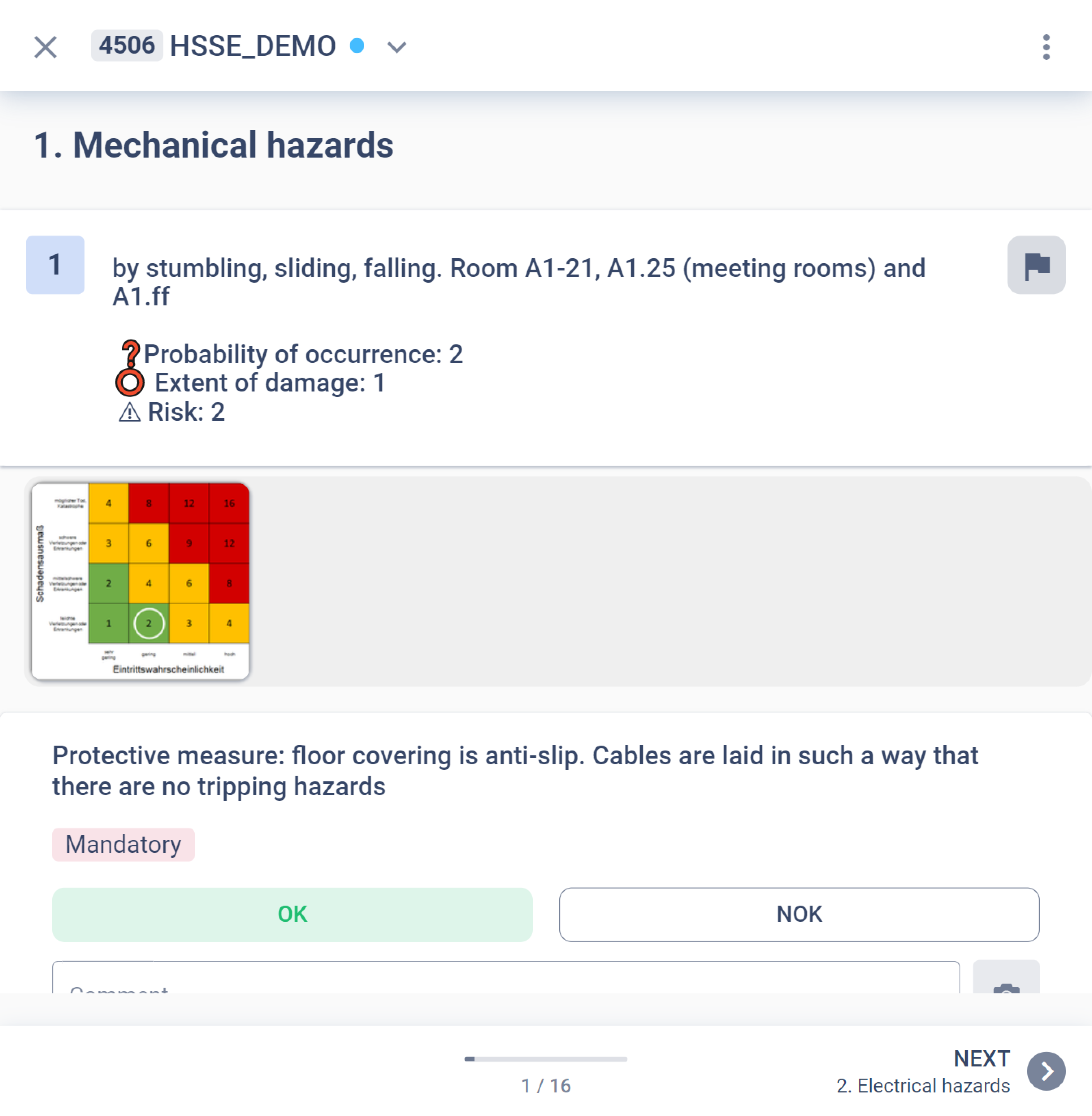

Safety instructions

Increase work safety by integrating typical safety instructions before starting an interactive process instruction.

Markings

Add markers, icons, and characters to increase the intuitive comprehensibility of digital documents.

Error Images

Incidents and findings can be digitally documented and analyzed across any number of process runs.

Use test logics

Use individual test logics. This guides your employees intuitively and efficiently through the process.

Signature Field

Confirm the execution of your processes directly on the tablet or smartphone via digital signature.

Incidents-Management

Unforeseen incidents can be created, tracked and processed as tasks on any checklist or instruction.

Wide range of applications

With Operations1 you can create your checklists and process instructions in no time and scale them company-wide. Whether it’s a cleaning checklist, shift handover protocol, HSSE checklist, fire safety inspection, plant tour, 6S, plant audit, safety briefing or process sheet. Benefit from an intuitive interface for your employees across all production-related support processes.

Do you employ external personnel?

No problem. Many manufacturing companies use external personnel for facility management tasks such as cleaning activities. With Operations1, you can create external users, track process progress via live monitoring and have comprehensive transparency on findings.

Get to know Operations1 in a live demo

We would be happy to show you the functions of Operations1 in an individual live demo and answer your questions.