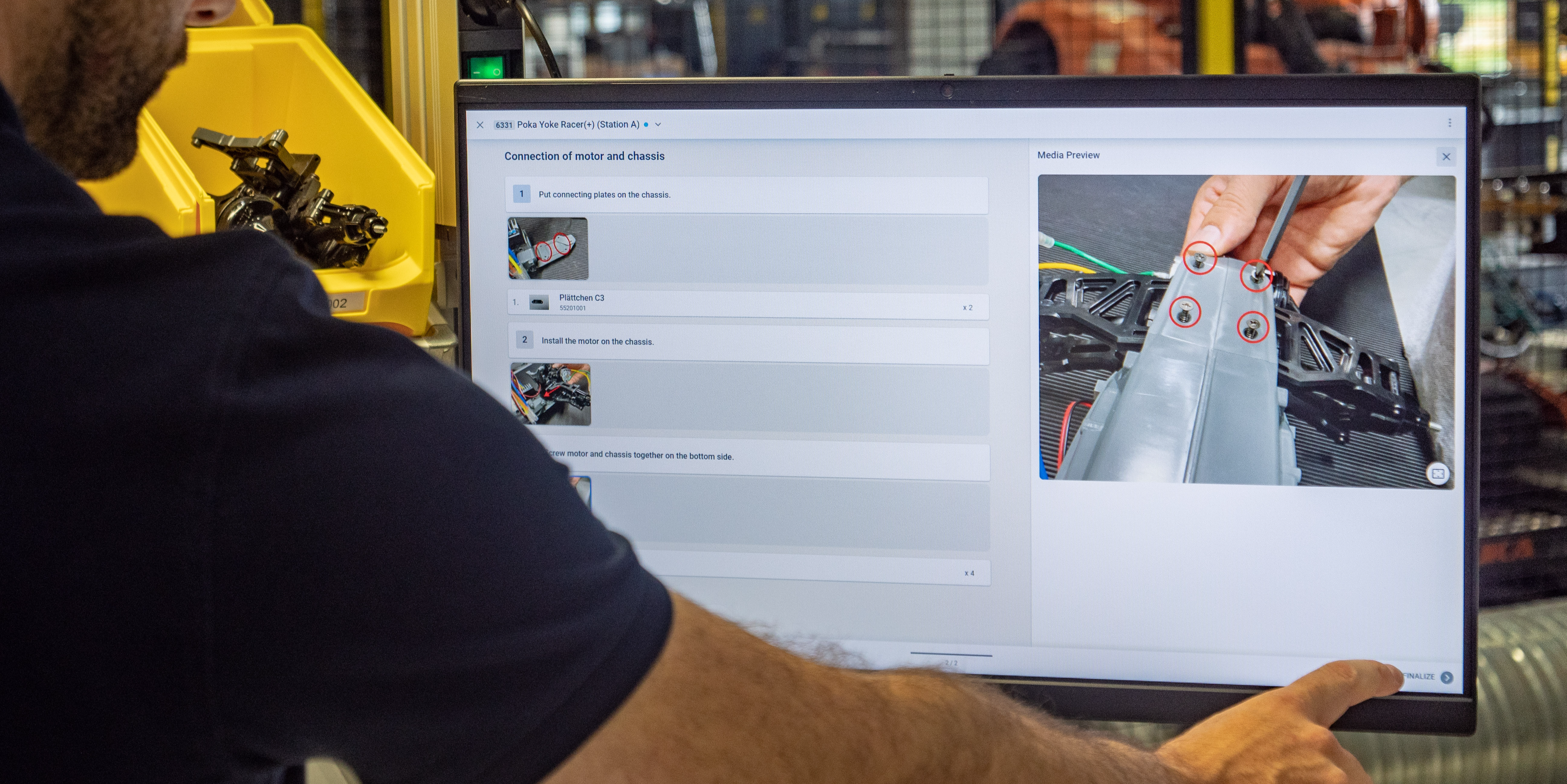

Intuitive digital assembly instructions with Operations1 software

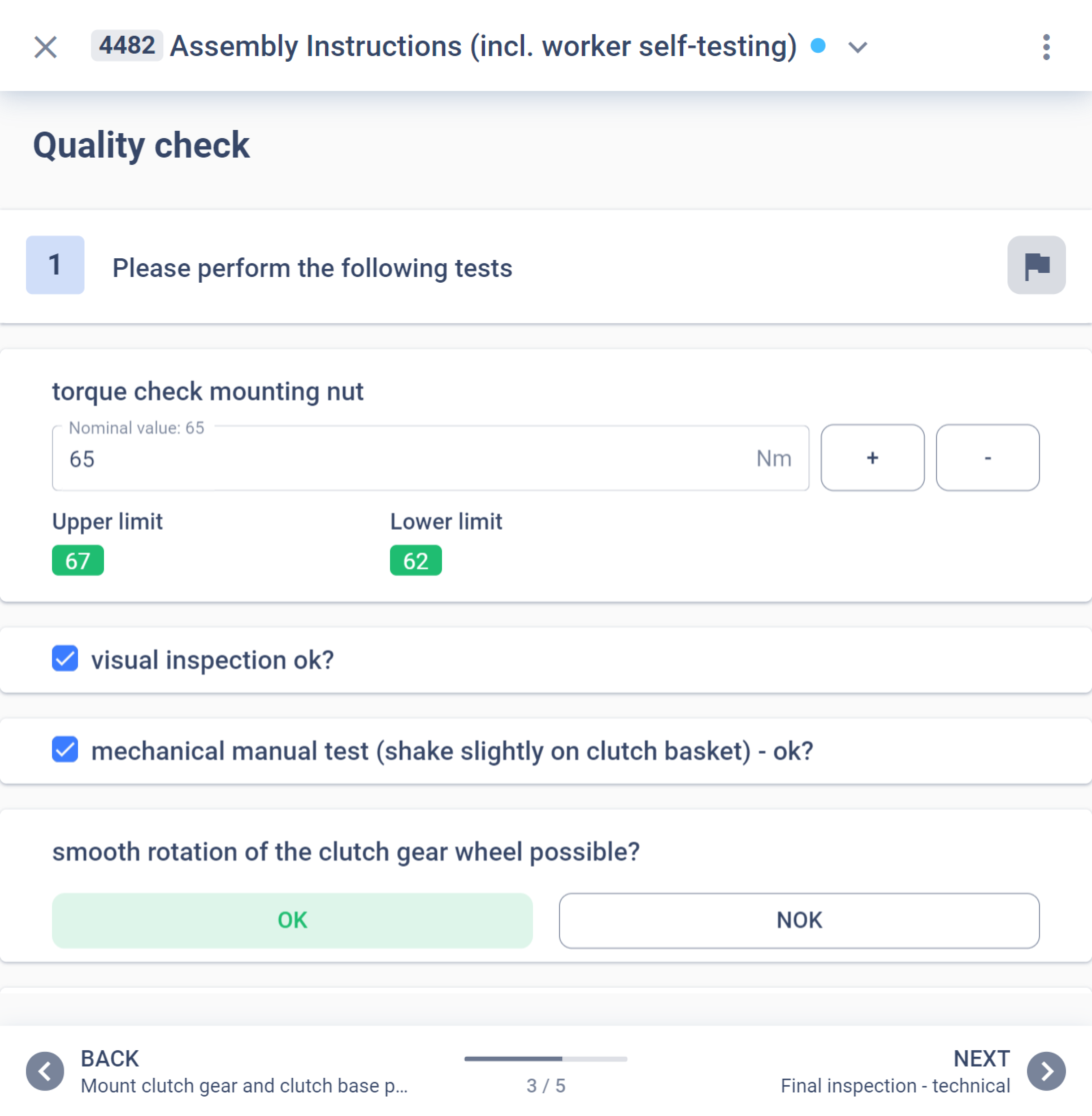

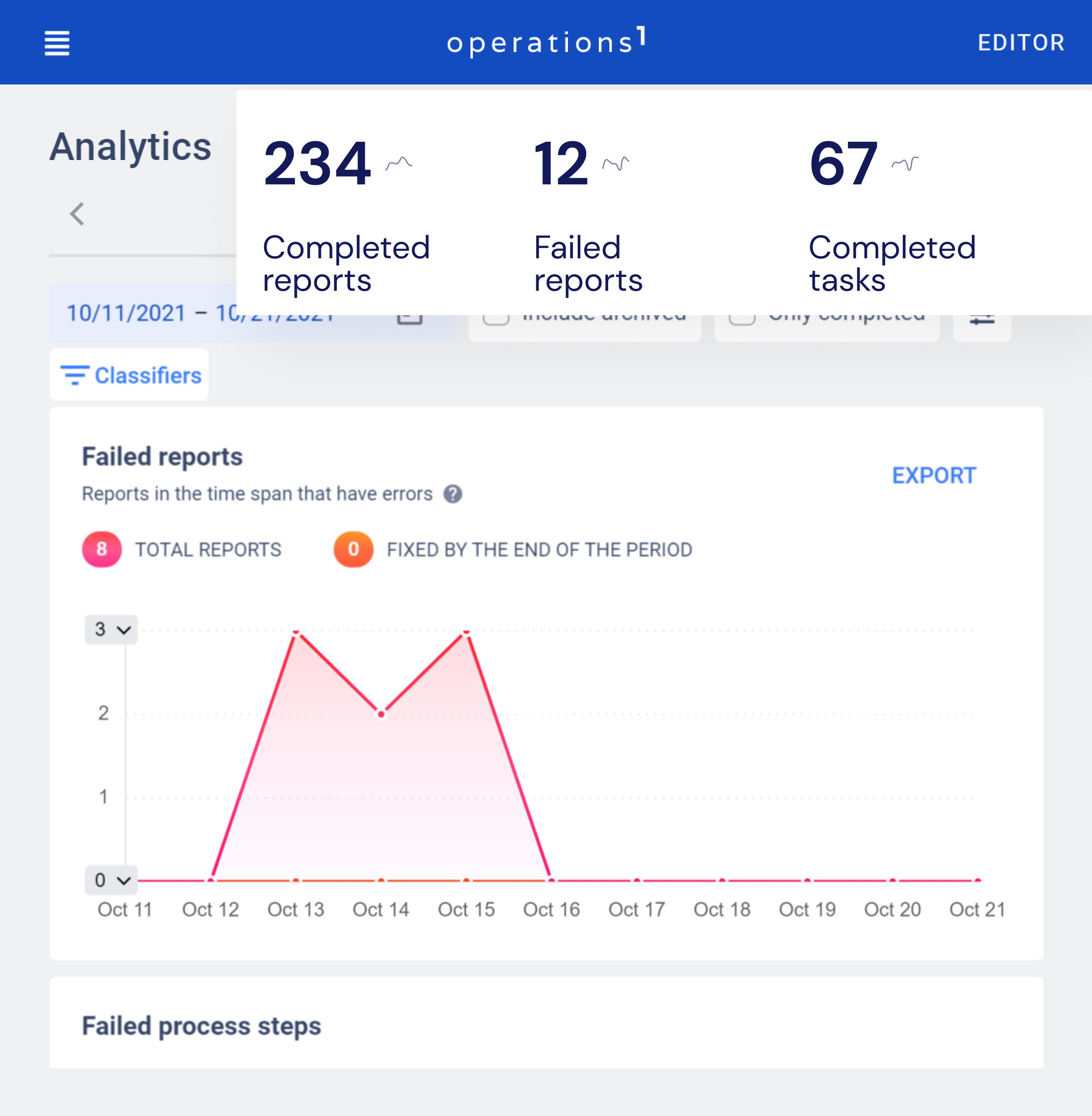

Using image and video-based assembly instructions, your employees deliver highest quality and efficiency regardless of location, language or qualifications. Integrated checkpoints and media return make worker self-testing digitally evaluable.

Arrange a non-binding appointment with our team.

The Operations1 software in assembly

With Operations1, you enable intuitive and simple operational execution of assembly and inspection processes. Put an end to text-based work instructions, time-consuming creation processes and long training periods for new employees.

Functions for industrial use

Drag and drop

Simplify the creation and updating of your documentation

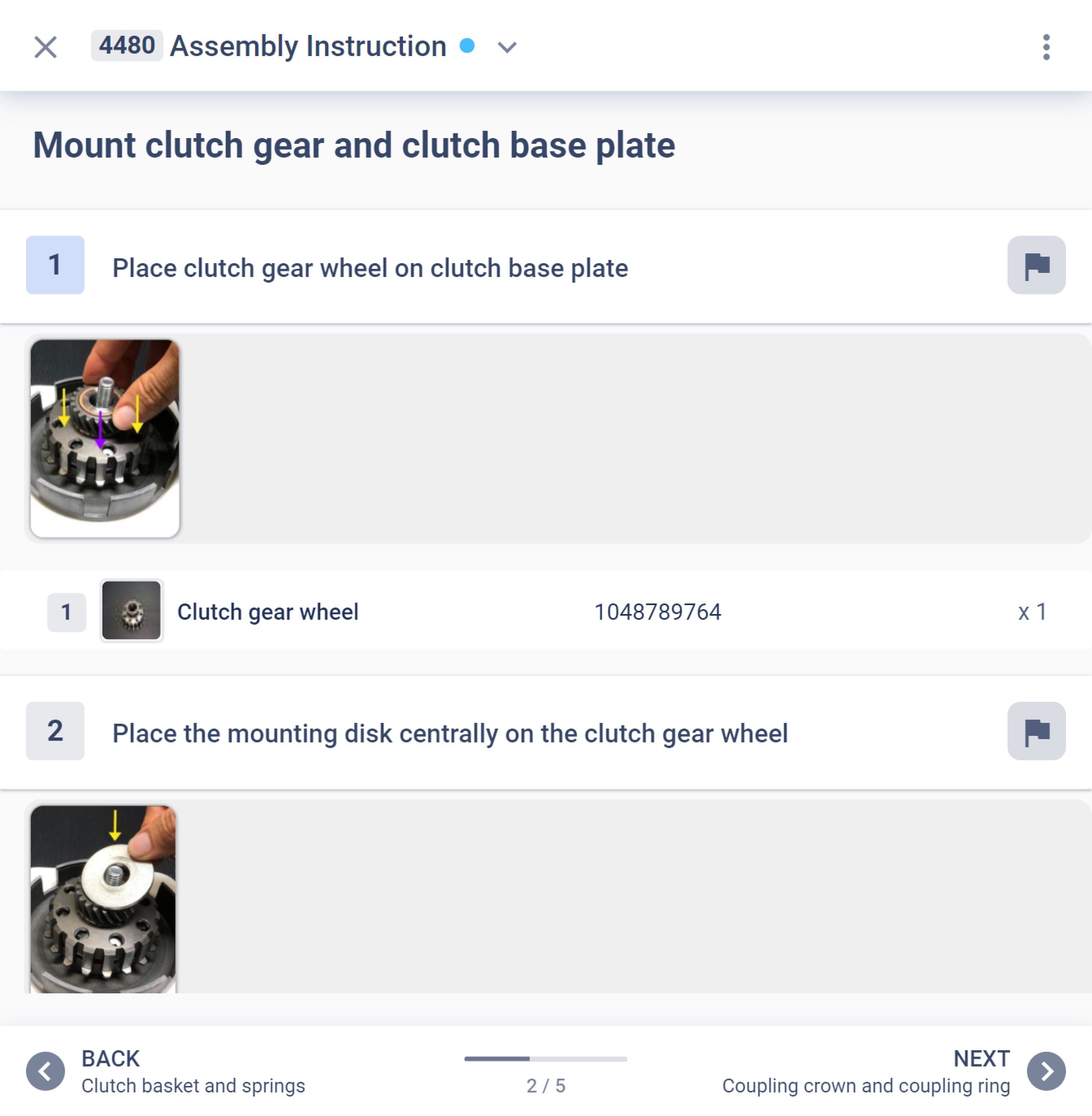

Pictures and videos

Include images and videos in your documents to increase comprehension

Media editor

Increase comprehensibility by easily editing images and videos in Operations1

Change notifications

Inform your staff when a document changes and always use a point of truth

Multi-language

Deliver both software and your instructions in all the world's major languages

Modular structure

Create recurring elements as modules and create a point of truth

QR-code scanning

Start processes via search function or by scanning a QR code

Connection

Synchronize production orders with your MES or ERP system

IoT integration

Use IoT tools and report values error-free and automatically into your digital checklist

Contact our experts!

Arrange a non-binding appointment with our team. Our experts will be happy to advise you on the next steps on your way to a digital assembly based on your individual use case!