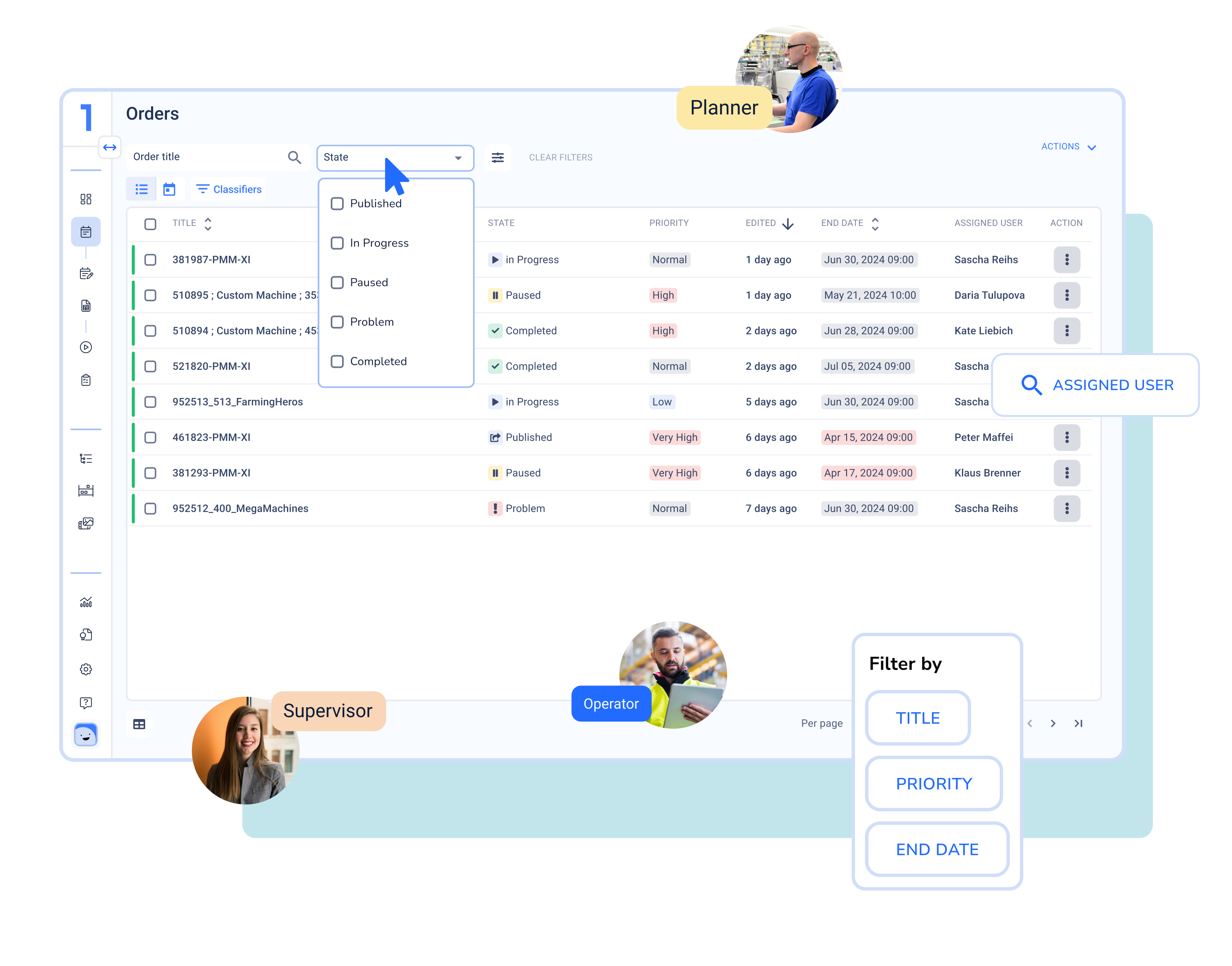

Ensure higher efficiency in production with order management in Operations1

Effort-reduced order planning

Save valuable time when planning one-off or recurring orders and tasks.

Reduce your planning effort and keep track of upcoming, ongoing or completed orders in real-time.

Order planning with media breaks

Whether manufacturing or maintenance orders - order planning generates unnecessary work for many manufacturing companies due to existing media disruptions. The process often looks like this:

Digital planning of orders in Excel, MES etc.

Transfer of pending orders to analog whiteboard

Manual provision of paper-based orders in production folders or order trays

Employees may have to check the documents again before they can start working on them

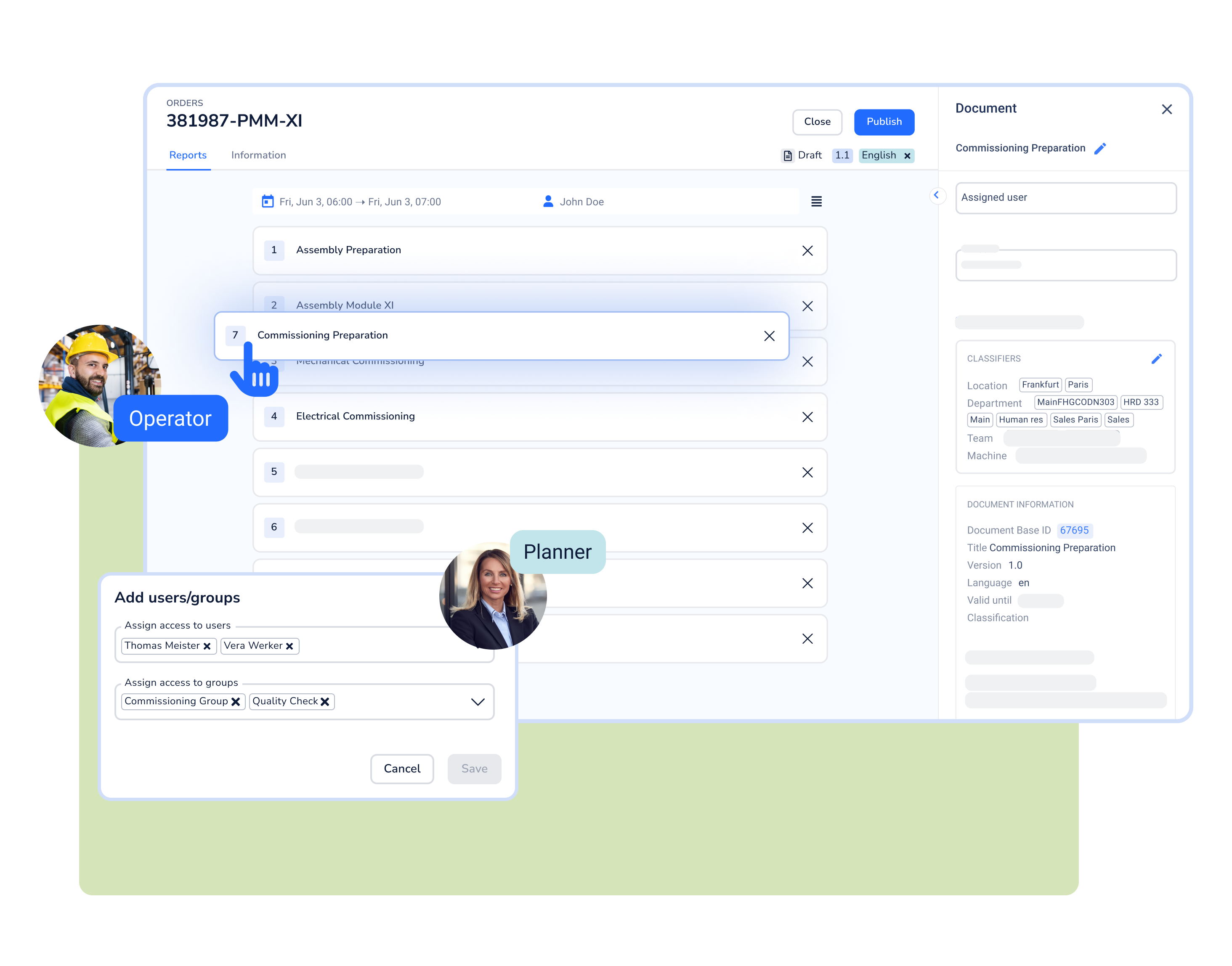

Orders professionally planned and made available ready-to-go to your employees

Orders

Create one-off orders with the right documents and assign them to your employees.

Rules

Automate the creation of recurring tasks by creating rules.

Detailed Planning

Refine the planning of your recurring orders on the basis of a detailed schedule.

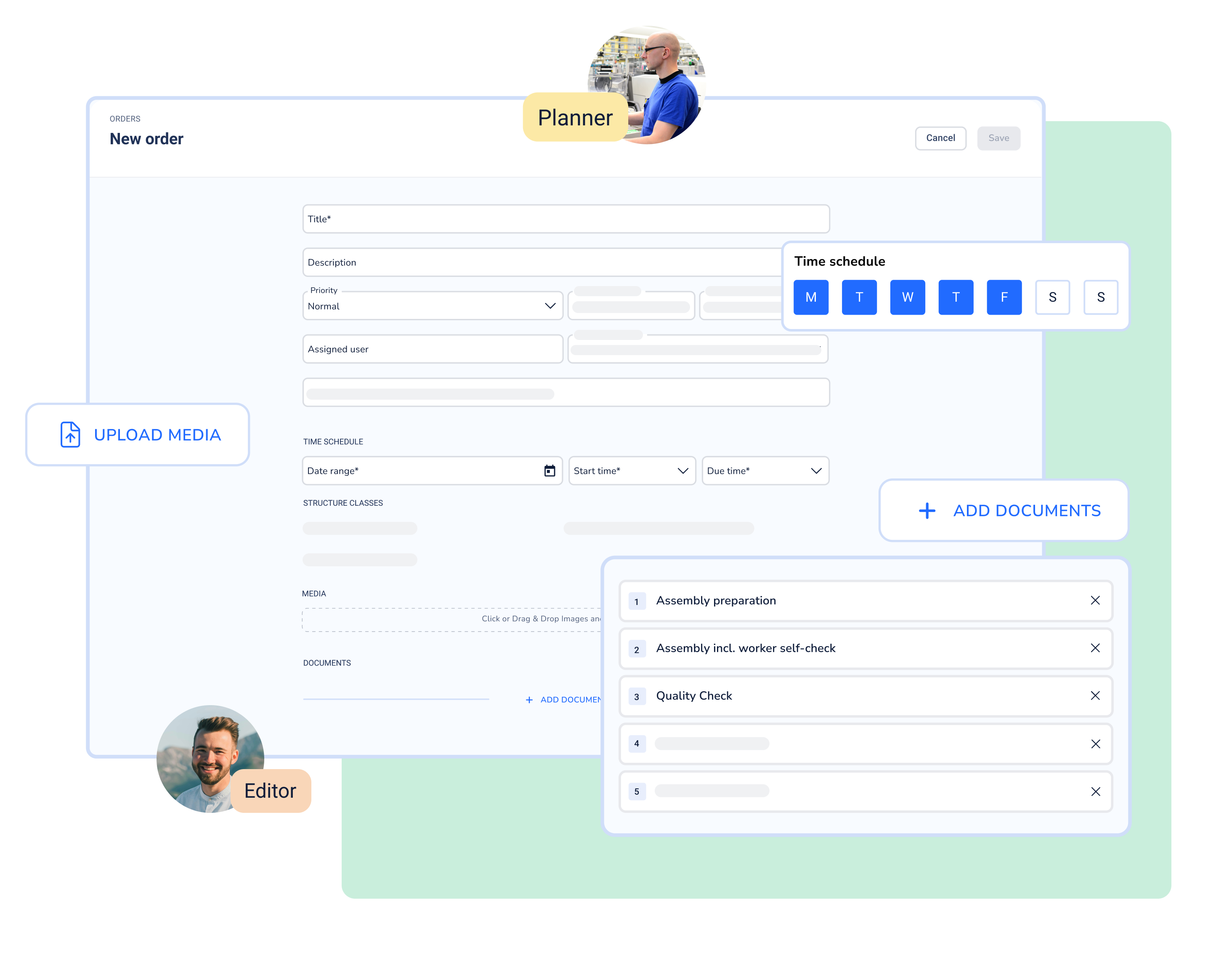

Plan and assign activities efficiently

Create new orders with just a few clicks and assign priorities, employees and due dates to them.

Reduced effort for order creation and planning

A central point of truth for your orders

Increased process reliability, as tasks are not forgotten

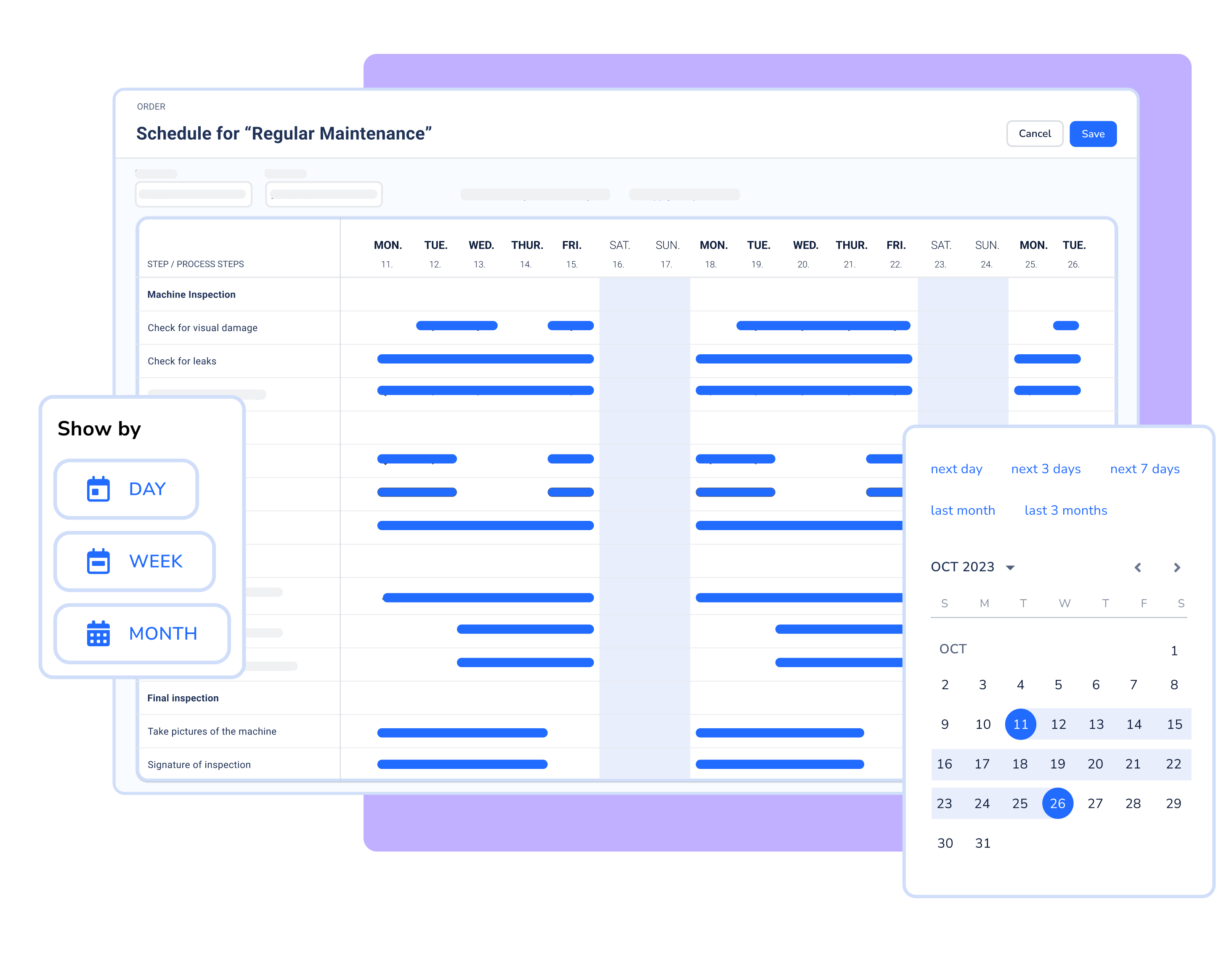

Orders planned down to the last detail

You can plan recurring tasks such as maintenance work on a monthly, weekly or daily basis using rules and have them created automatically.

The Scheduling Rows feature also allows you to plan in even more detail: Select specific modules for the specific intervals. This allows you to adapt the activities to the needs of your production.

Reduction of order planning through automation

Reducing complexity in document management through module selection

Simplified execution for employees thanks to automatically tailored documents based on planning

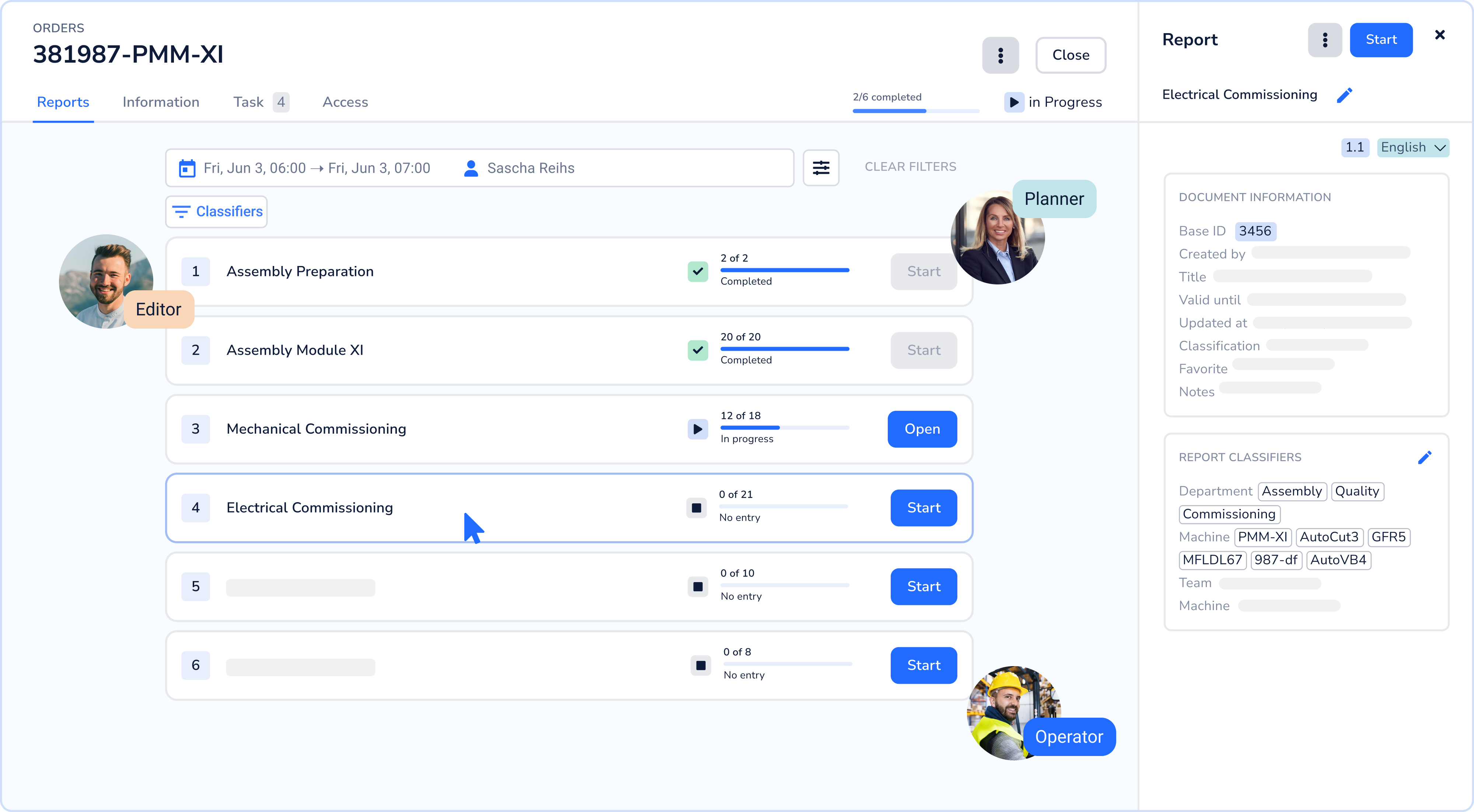

Process progress and status in real-time

See the status of your orders at a glance in the order overview. You can access individual orders at any time to gain a detailed insight.

Simple monitoring of order progress

Increased informative value for questions from other departments or customers

Seamlessly documented process data for CIP measures

Say goodbye to MS Office & paper

Contact us now and take the first step towards digitizing your employee-led processes with us.