Digital inspection documentation for high-performance and secure production processes

Structured execution of audits and inspections to quickly identify and rectify deficits

-80% time spent on 6S audit

-67% documentation effort

Fast collaborative problem solving

Analog inspections:

Paper jam instead of improvement

Paper jam instead of improvement

No regular process

5S/6S audits, Gemba Walks, safety walks or inspections take place infrequently and sporadically

There is a lack of a standard for internal audit processes that is comparable across departments and plants

High effort for your employees

Observations have to be elaborately documented with paper or a separate camera

Paper-based inspections make it difficult to solve problems quickly and collaboratively

Video or photo documentation must be added separately to the protocol

Difficult analysis and traceability

Audit results recorded in analogue form must be manually transferred to software or be digitized

Difficult traceability of measures implemented to comply with or improve process or occupational safety standards

Findings documented digitally and regularly

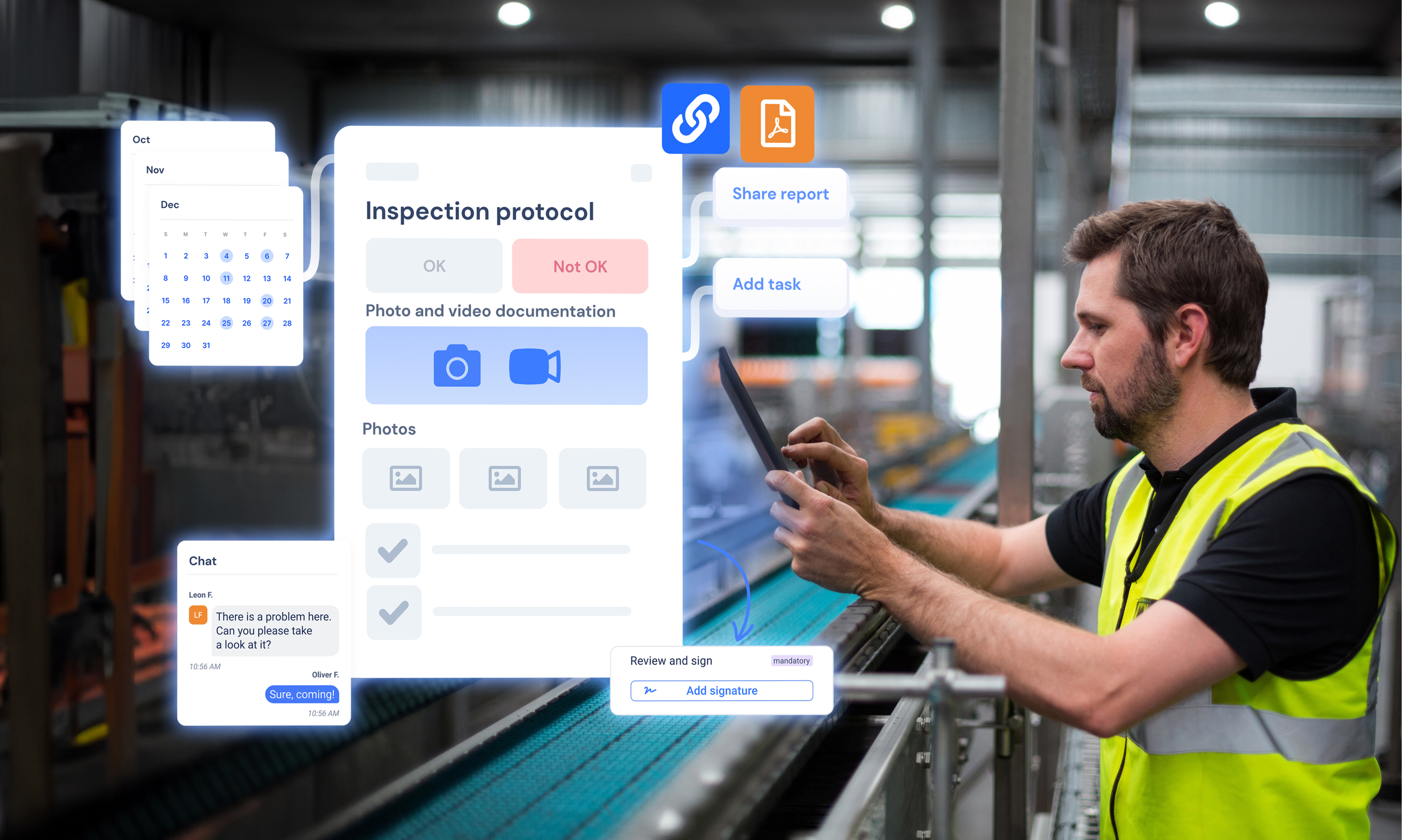

Standardized execution and complete documentation of inspections through intuitive instructions

Schedule recurring tasks for safety walkds and inspections so that they are carried out regularly by date

Have findings captured directly via smartphone or tablet camera by photo or video

Professional audit reporting for internal and external stakeholders

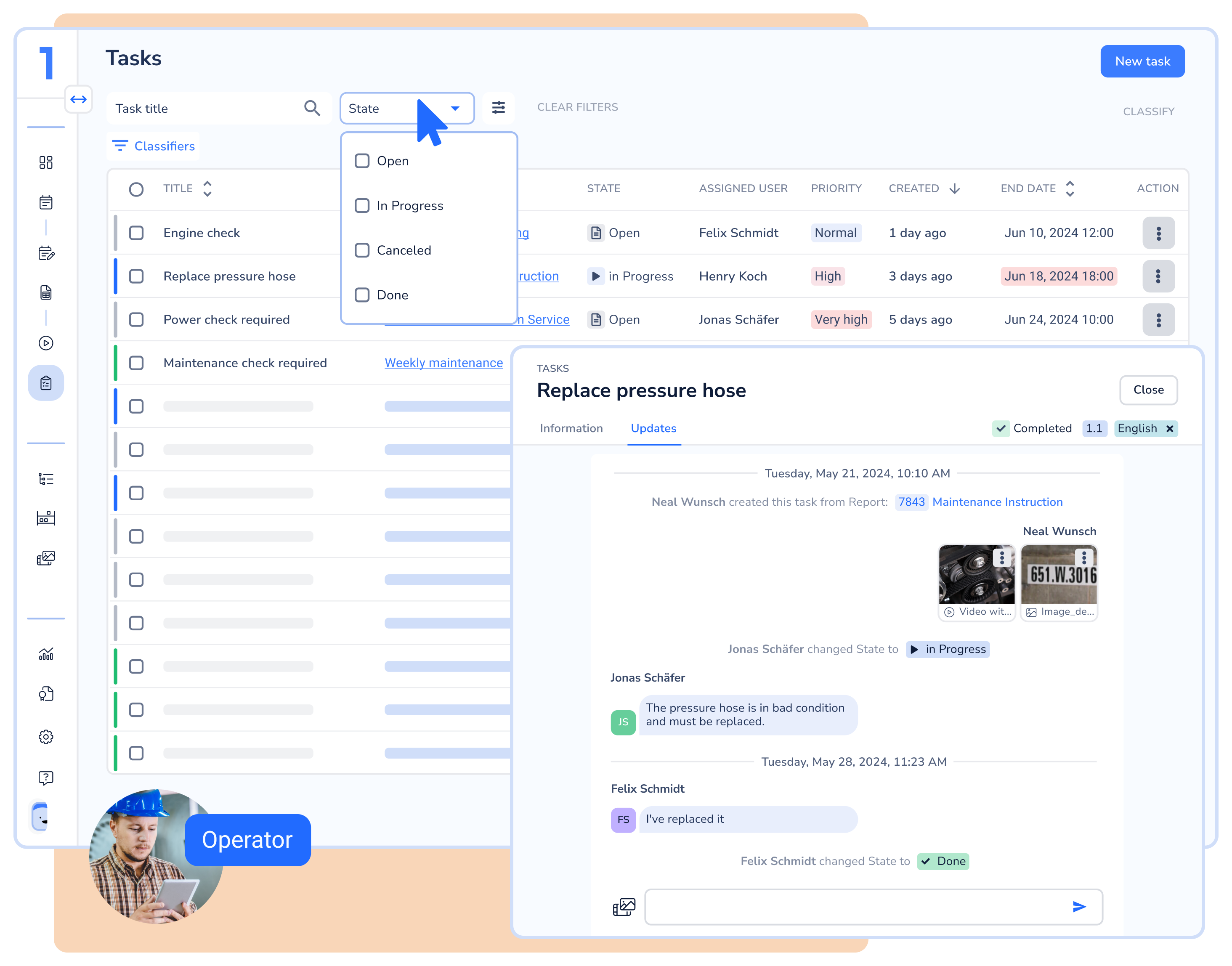

Problems can be assigned directly to individual employees for quick resolution using the task function

Automatically generated reports provide complete documentation for audits and traceability

Share your reports digitally and easily with other departments and external auditors or customers

Schedule a meeting

Take advantage of our team's many years of experience and get in touch with our product experts.

A cost-free discussion about your use case and your problems

Demonstration of solution approaches using the Operations1 software

You will learn how you can benefit from Operations1 and how you can get started quickly