Digital error management for fast problem solving

Strengthen your team communication and error documentation for better processes and cost reduction

-67% documentation effort

-100% walk times

Transparent error documentation

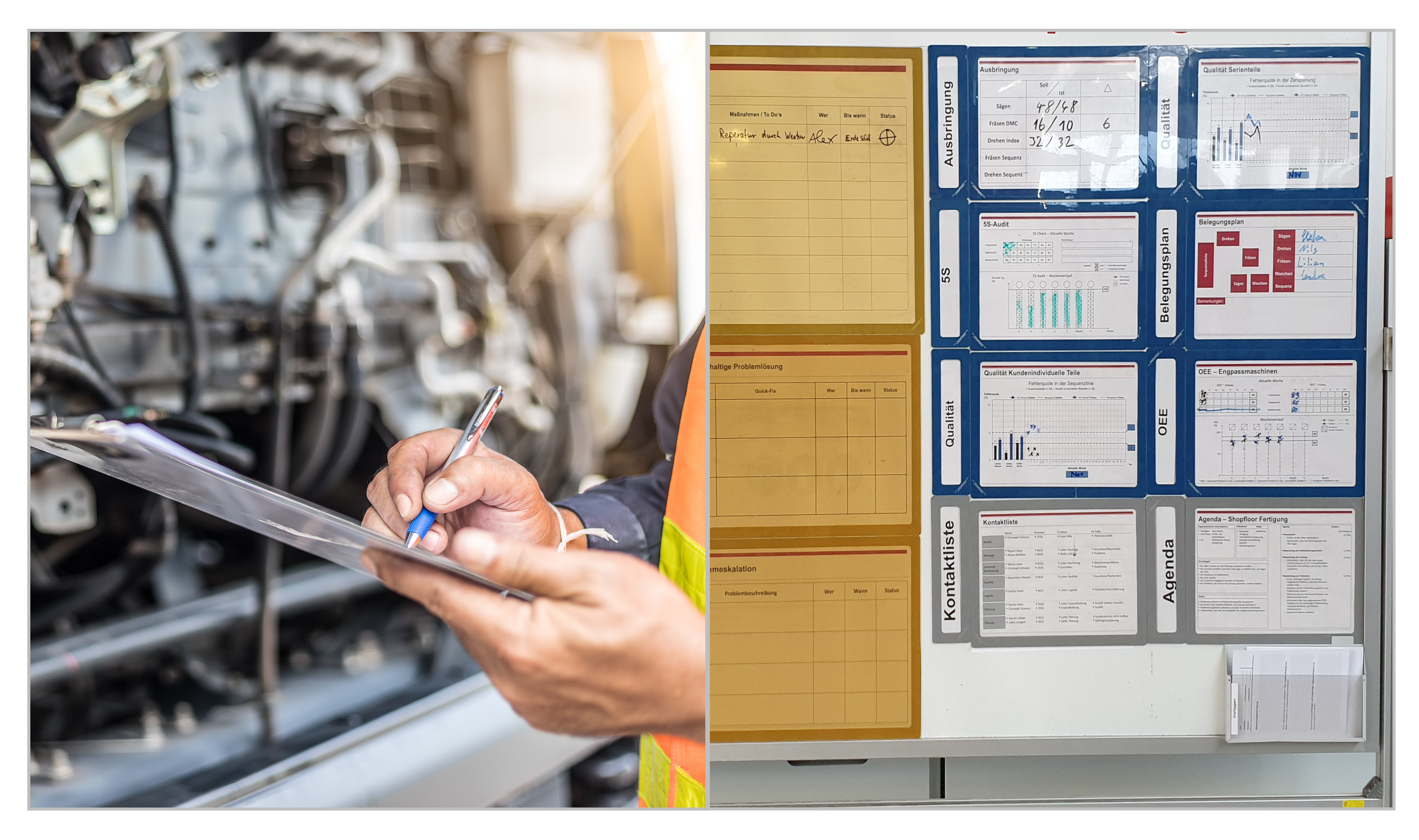

Intransparent error management

at a snail's pace

at a snail's pace

Inefficient documentation of errors and problems

Errors and problems are laboriously collected on paper, whiteboard, etc.

Analog documented findings must later be transferred to software by hand

Problem solutions are not documented in a way that adds value for the future

Long response times due to inconsistent communication

Employees have to leave their workstation for questions and lose valuable working time due to long walk times

The constant change of communication channels leads to a loss of information and long response times

Slow problem solving and CIP measures

Problems are solved too slowly due to analog and non-standardized processes

Error research with folders and paper is laborious and time-consuming

It takes a long time for CIP initiatives to find their way back into the operational process

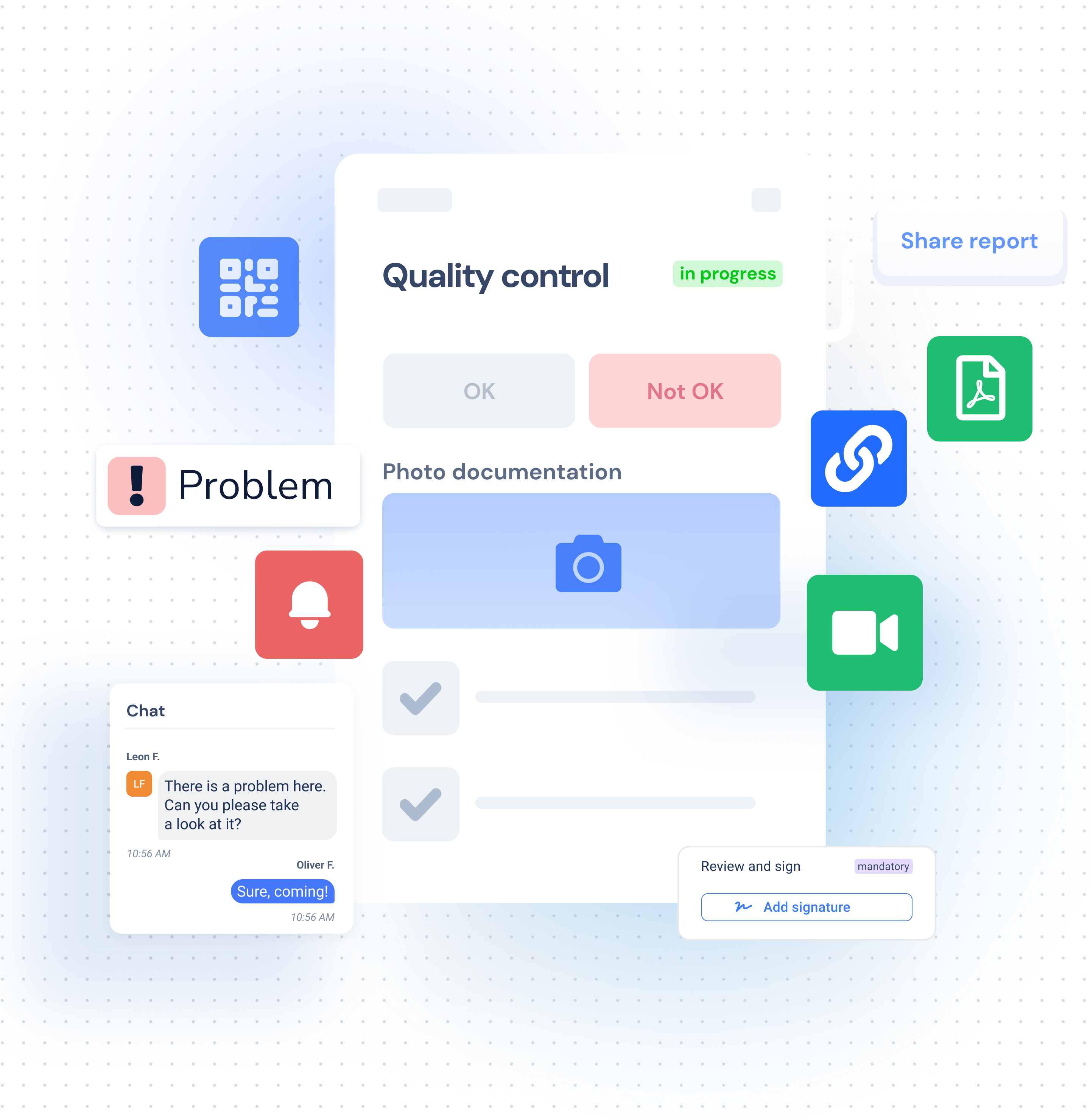

Problems captured digitally and efficiently

Realize more efficient error management with digital error collection cards, test protocols, inspection checklists, etc.

Document errors and incidents directly in digital checklists using photo and video functions

Your employees can create error, quality or maintenance reports directly in the process

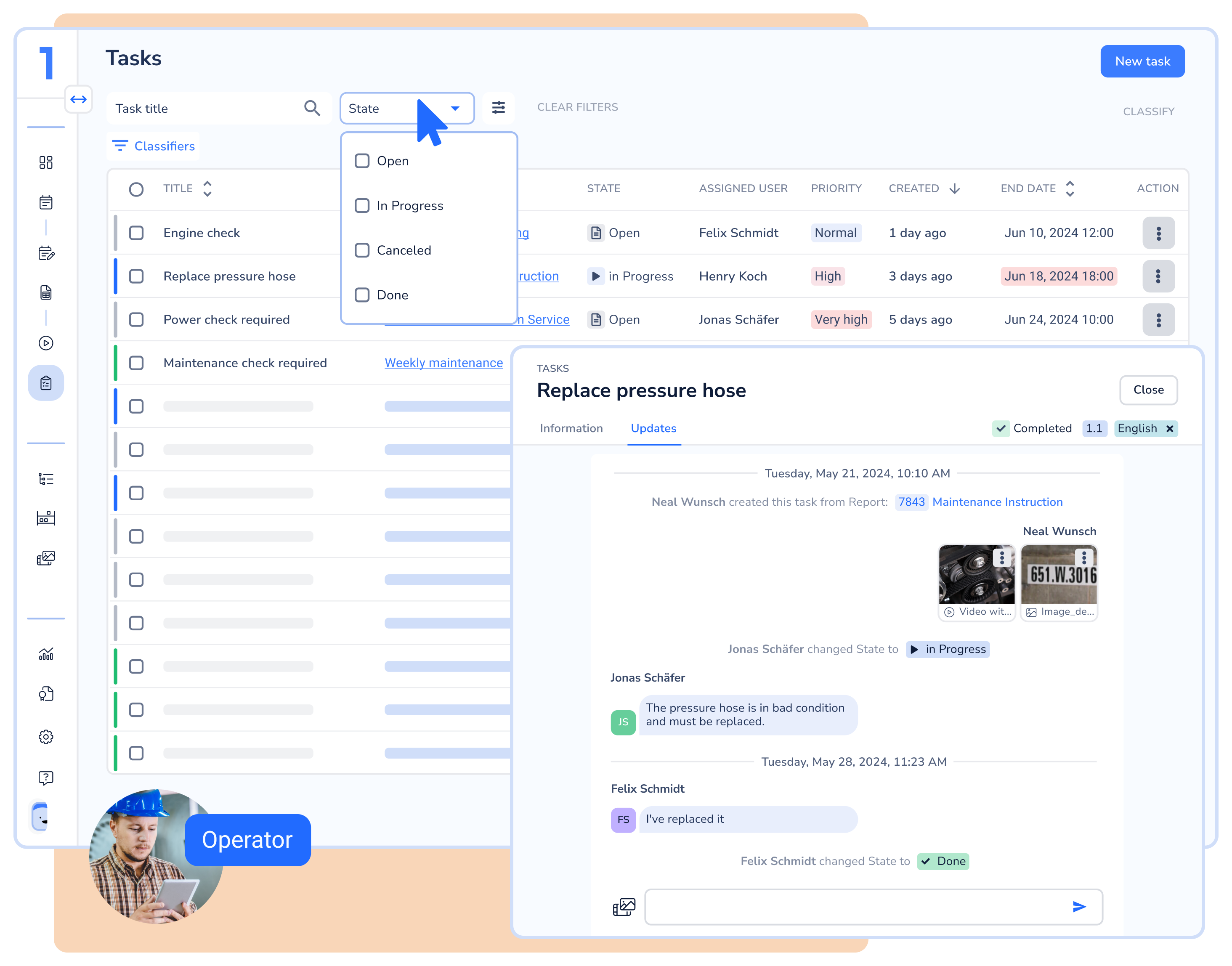

All tasks in view and solved transparently

Track, manage and solve all tasks transparently, collaboratively and in real-time via chat for you and your employees

Ensure that all tasks are carried out through a standardized communication proce

Derive CIP measures and quickly push them back into the process via Operations1

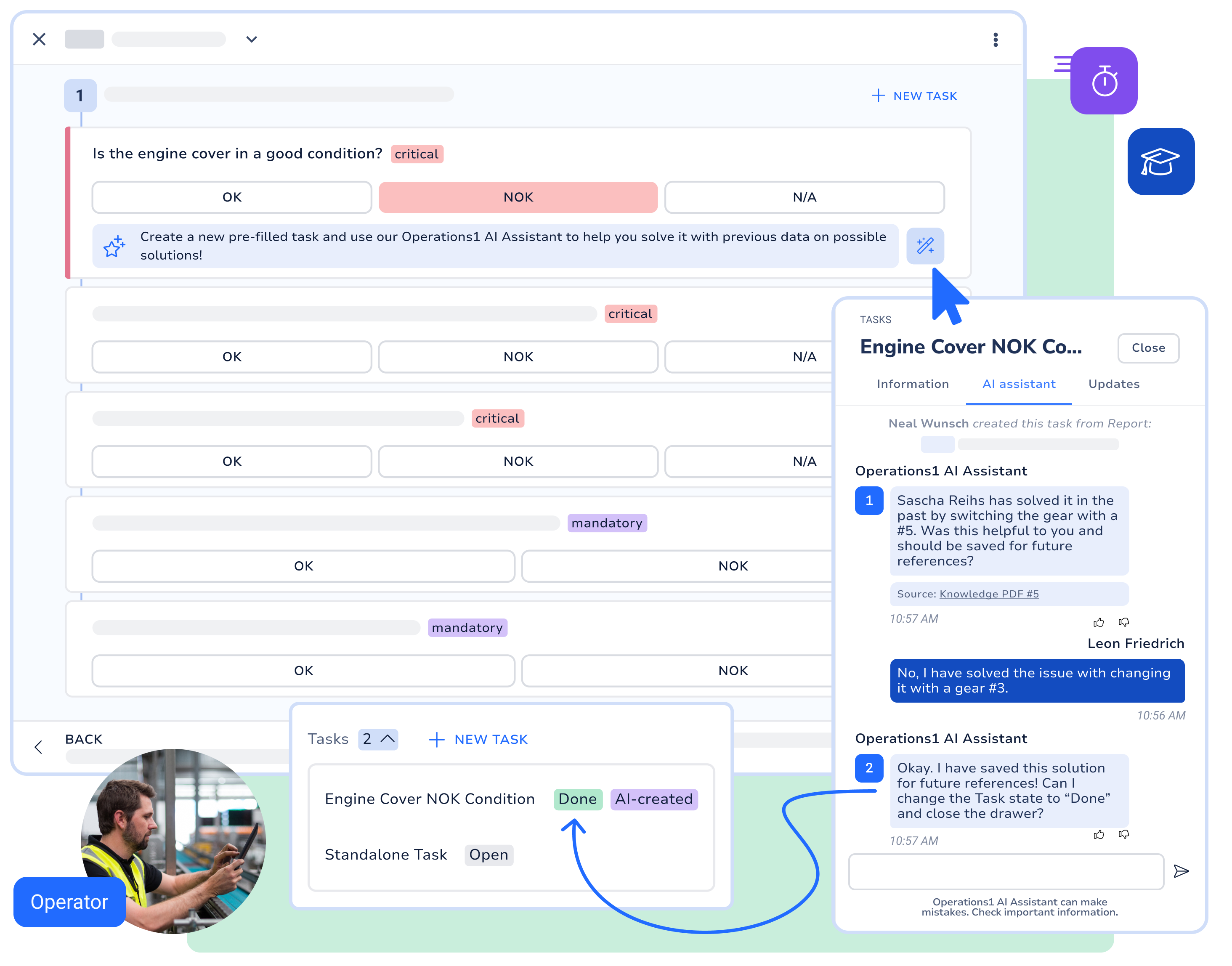

Incidents solved efficiently with AI support

Use your existing knowledge to solve problems and give your employees real support in resolving incidents with the AI Assistant.

Effectively using your existing knowledge to solve recurring problems on the shopfloor

Reduce the time employees spend searching for relevant reports, manuals, and other documents

Fast problem solving through AI-supported solution suggestions based on the knowledge you have uploaded to Operations1

Schedule a meeting

Take advantage of our team's many years of experience and get in touch with our product experts.

A cost-free discussion about your use case and your problems

Demonstration of solution approaches using the Operations1 software

You will learn how you can benefit from Operations1 and how you can get started quickly