Digital checklists for easy documentation

Compliant and efficient documentation of your production processes

-67% effort for document management

100% transparent documentation

-67% documentation effort

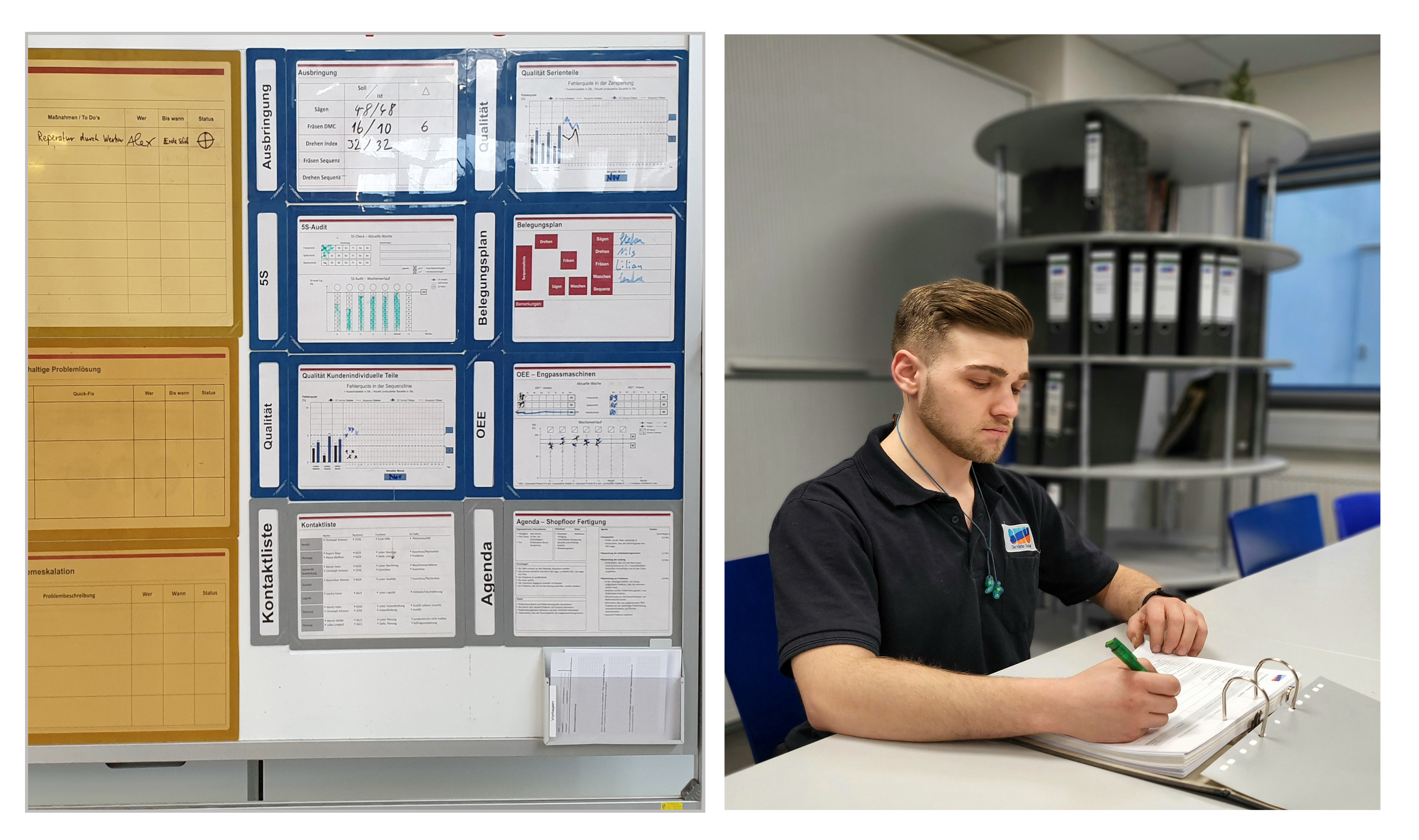

Documentation as in the 90s

Logging is done with various tools & media

Employees document using many different media such as paper checklists, whiteboards and digital cameras

There is a lack of a consistent, comparable documentation standard for adhering to compliance requirements

High effort with risk of errors and documentation gaps

Employees have to document assembly steps and test results laboriously on paper and transfer them to software

Paper-based documentation without control mechanisms harbors high potential for documentation errors and reporting gaps

Little transparency and inefficient traceability

The work progress of employees is not immediately accessible

Analog and partially digitized protocols and documentation are not immediately available

Time-consuming research and tracking when inquiring about orders and error logs

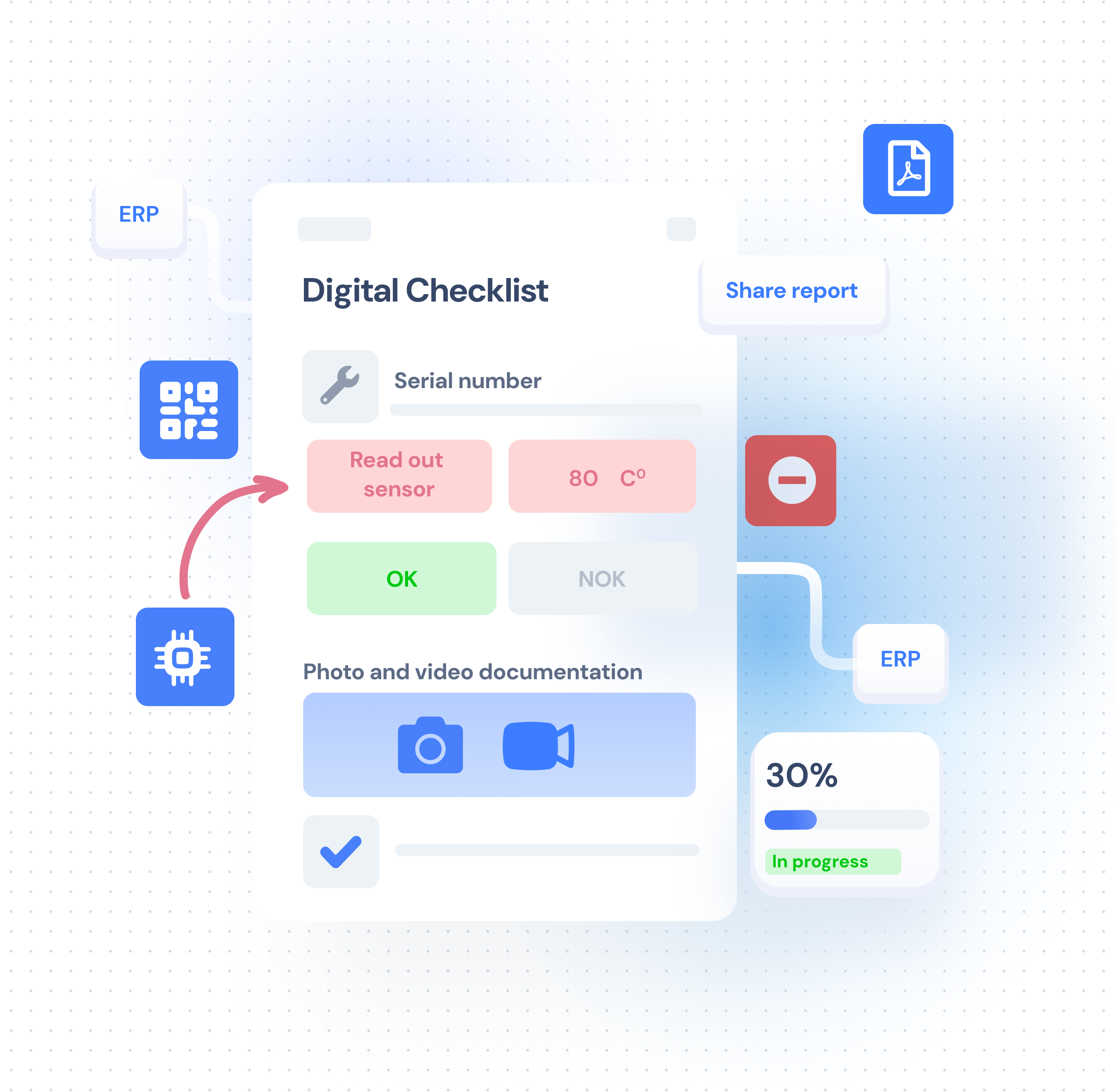

Results documented efficiently and digitally

Documentation of process steps and test results directly in the digital checklist

Measurements and serial numbers can be logged with a click by connecting external sensors or scanning barcodes

Process and error documentation directly via photo and video function using the smartphone or tablet camera

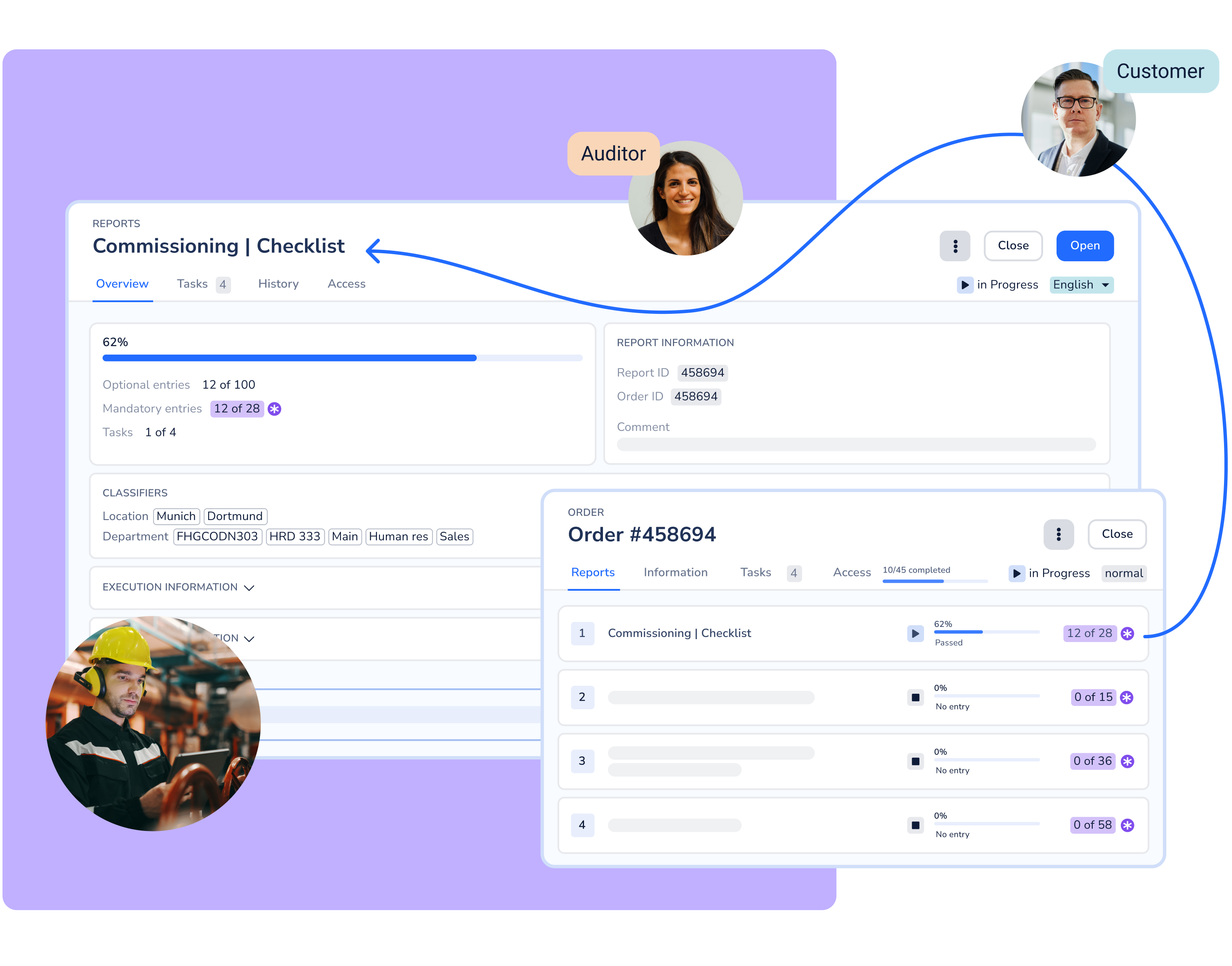

Full documentation for process optimization

Digital reports are generated automatically and log operational activities seamlessly in real-time

Research and analyze findings more easily with digital reports and filter functions

Easily share digital reports with your colleagues, customers or partners via link or PDF

Schedule a meeting

Take advantage of our team's many years of experience and get in touch with our product experts.

A cost-free discussion about your use case and your problems

Demonstration of solution approaches using the Operations1 software

You will learn how you can benefit from Operations1 and how you can get started quickly