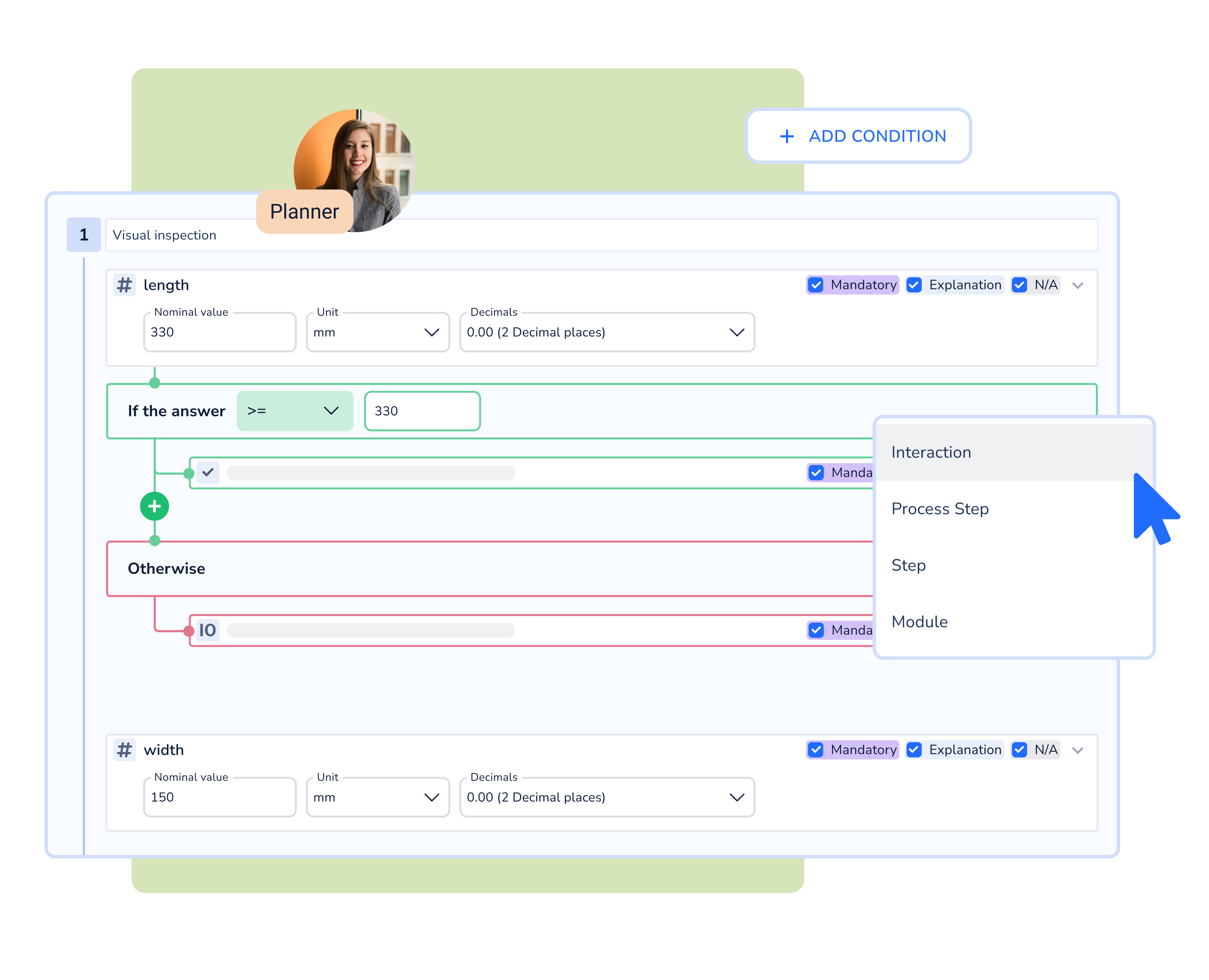

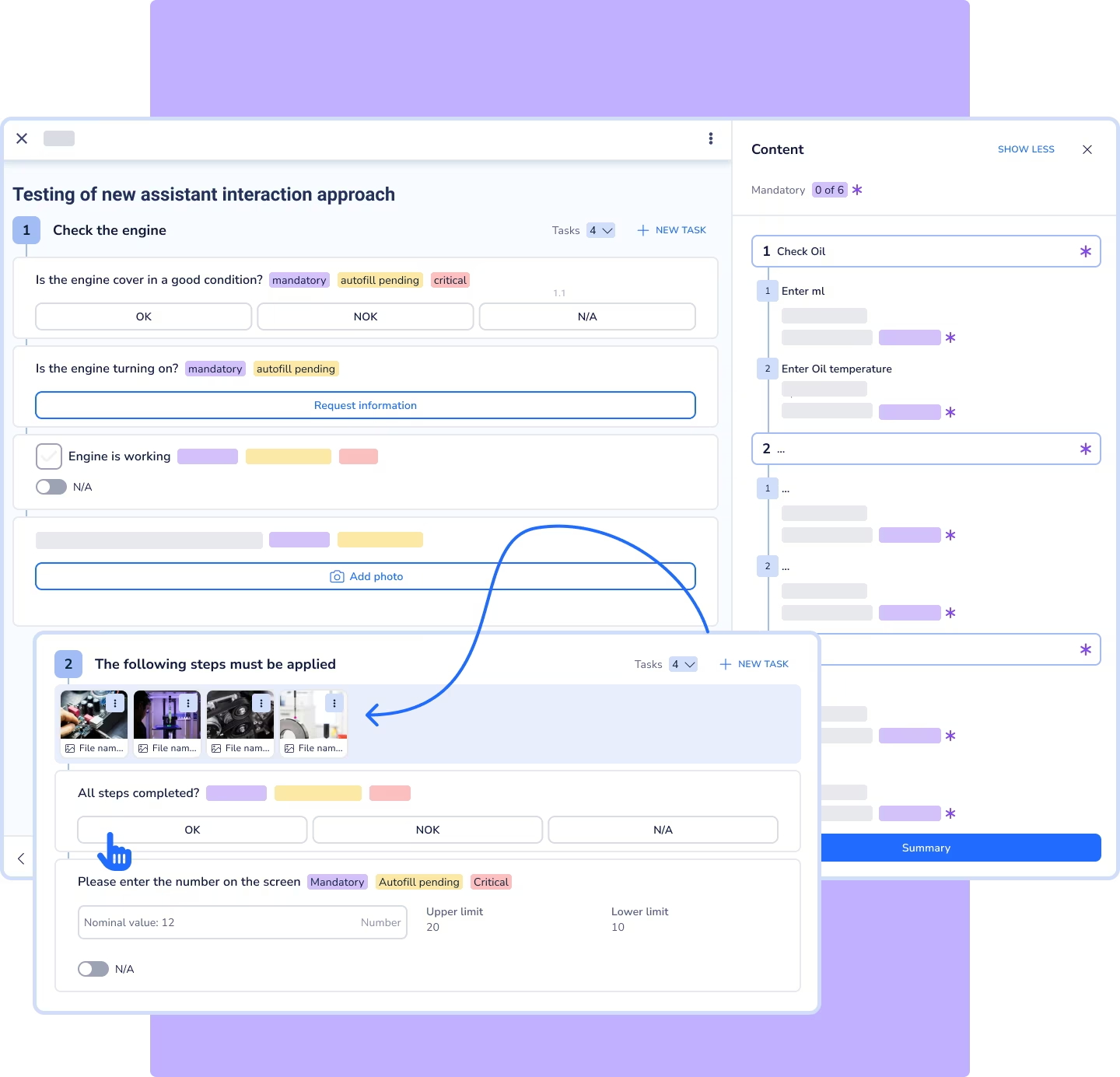

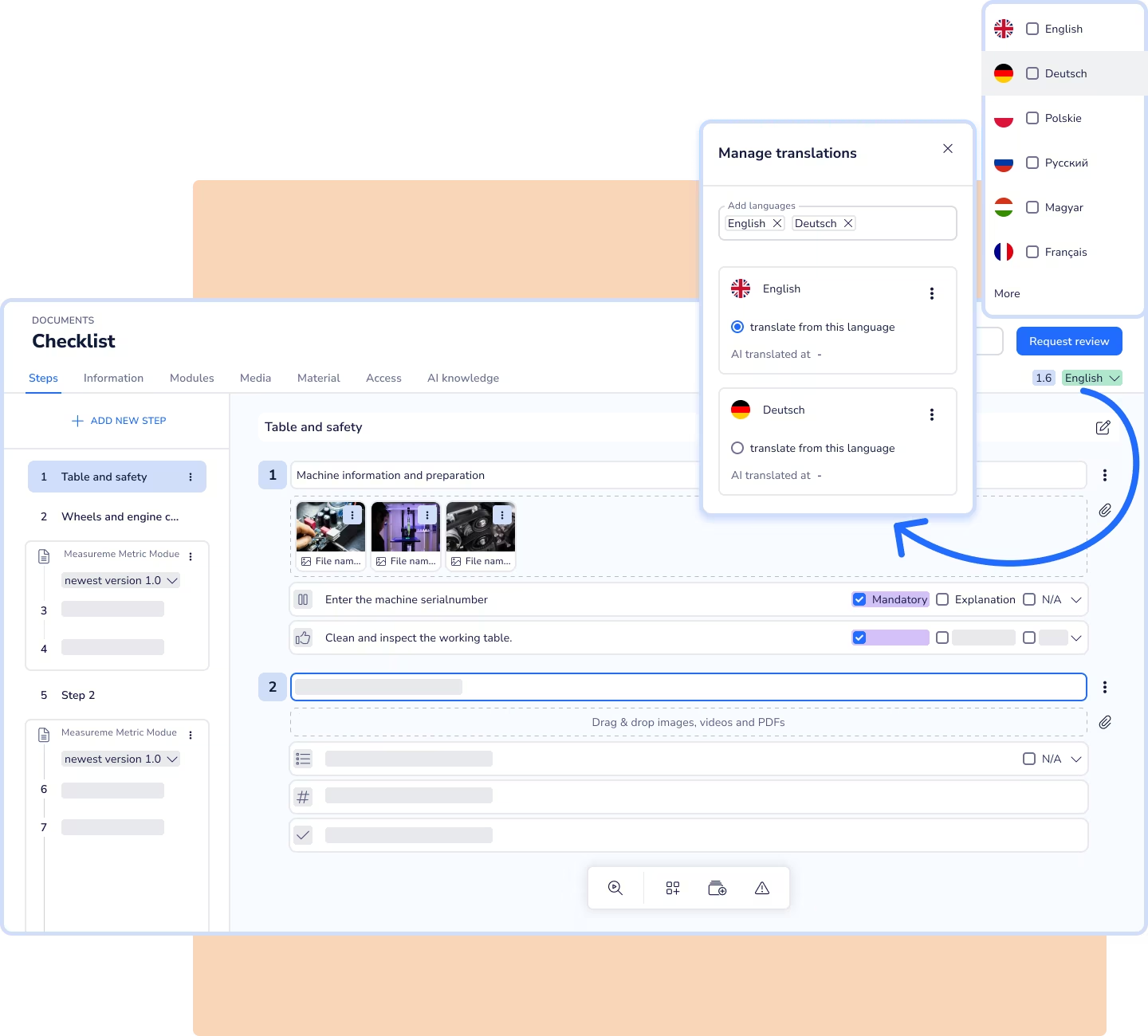

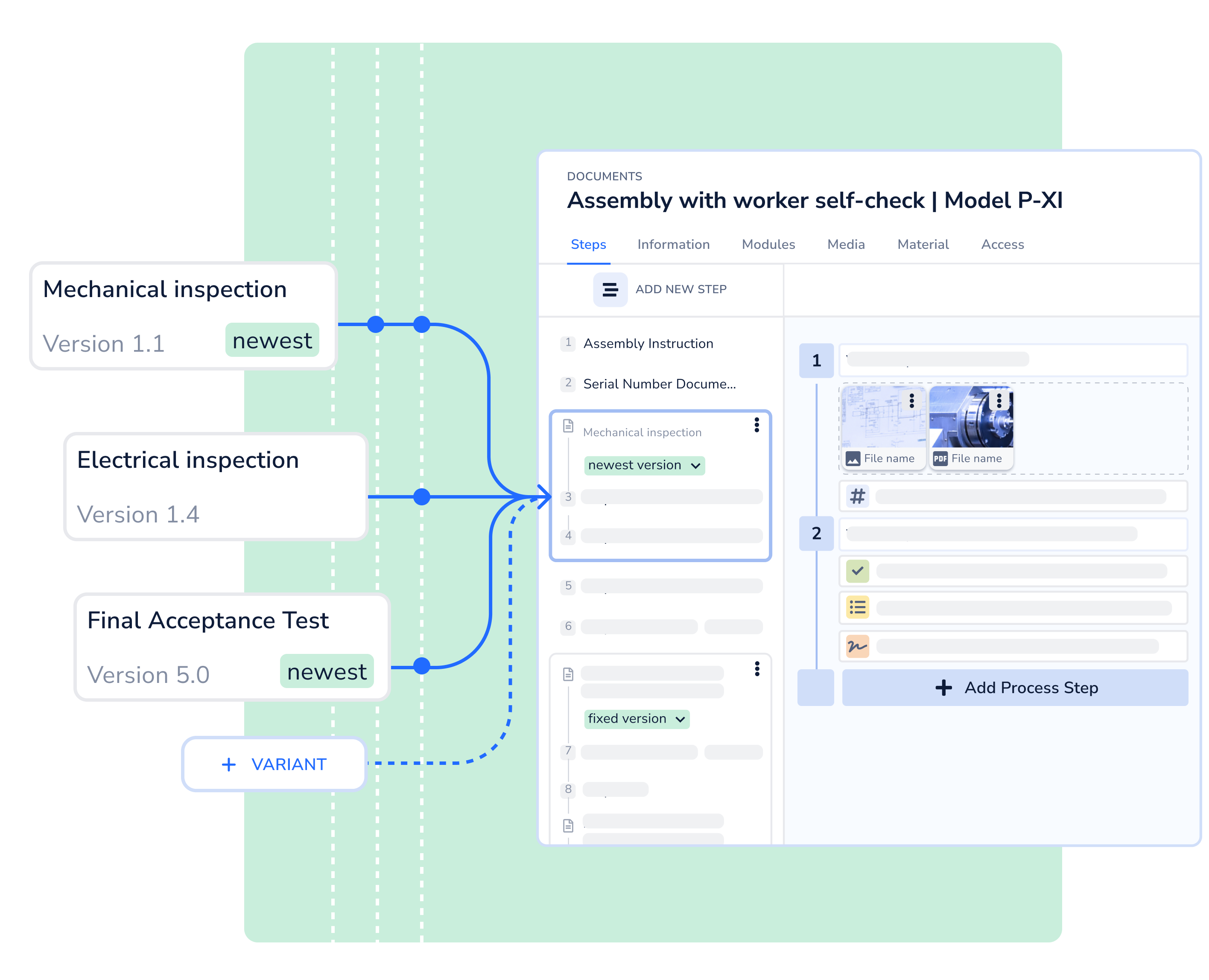

Digital checklists can be mapped in a variant-specific way by showing or hiding inspection steps depending on the context. Product variants, machine types, or order characteristics automatically determine which content is relevant in each inspection process.

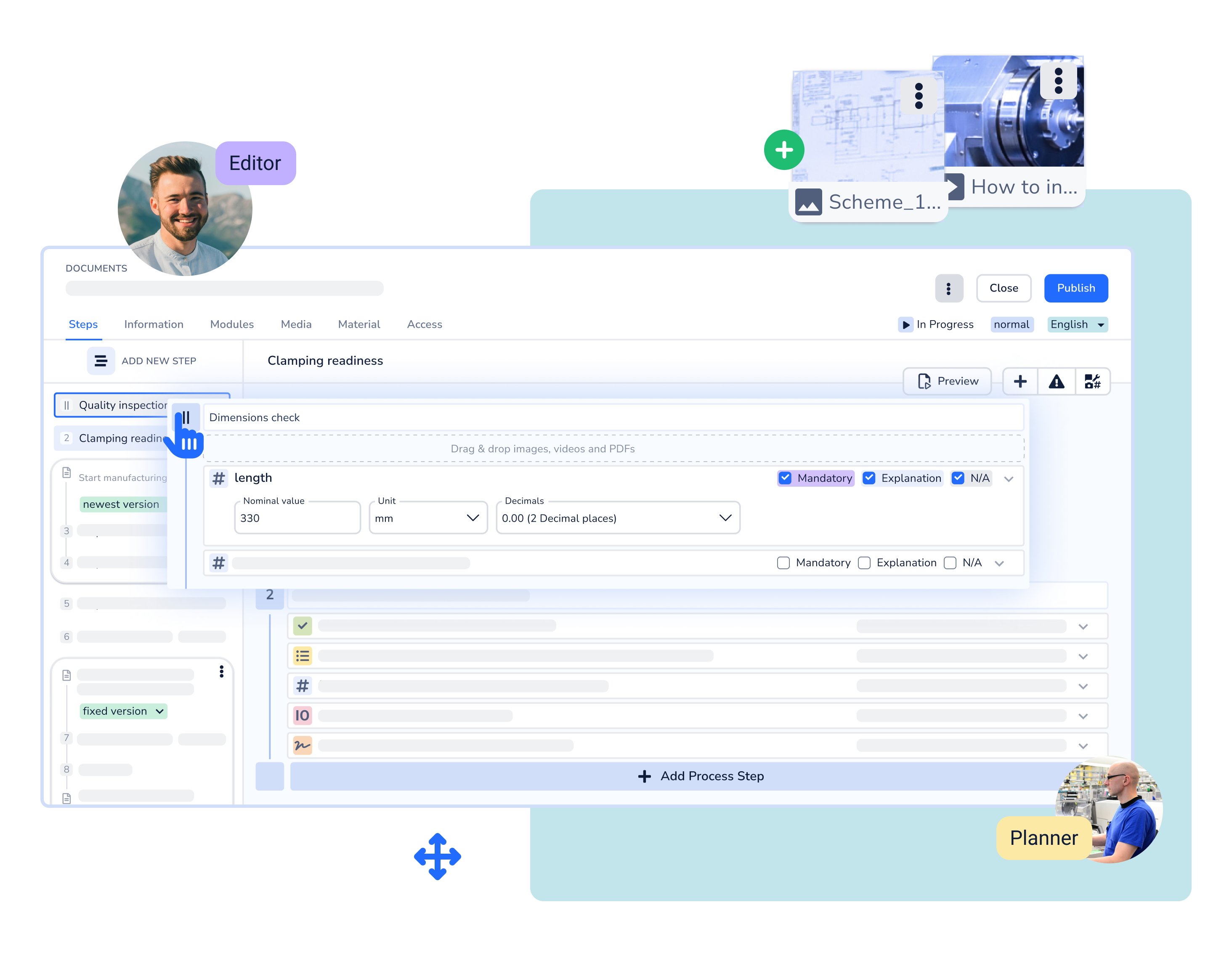

In Operations1, variant management enables a structured mapping of complex variant logic without unnecessarily complicating the checklist for workers. Reusable modules and centralized maintenance ensure that changes automatically take effect in all linked checklists.